A kind of production process of high temperature resistant precipitation antagonist

A production process and antagonist technology, applied in the field of high temperature resistant precipitation antagonists, can solve the problems of time-consuming and labor-intensive, delaying the production process, etc., and achieve the effect of increasing the cost of use, ensuring the quality of oil products, and reducing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A production process of a high temperature resistant precipitation antagonist is prepared from the following raw materials, and the parts are all parts by weight:

[0053] 3-5 parts of 2,6-di-tert-butyl-p-cresol; preferably 4 parts;

[0054] 3-5 parts of zinc dialkyldithiophosphate; preferably 4 parts;

[0055] Anticoagulant 0.5-1 part; preferably 0.8 part;

[0056] 0.5-1.5 parts of dispersant; preferably 1.2 parts;

[0057] 5-10 parts of ultraviolet absorber; preferably 8 parts;

[0058] The rest are base oil; the base oil includes the following components according to parts by weight:

[0059] 30-40 parts of polyalpha-olefin; preferably 35 parts;

[0060] 5-8 parts of polyether; preferably 7.5 parts;

[0061] Phosphate 10-15 parts; preferably 12 parts;

[0062] Triphenyl phosphite 5-15 parts; preferably 12 parts.

[0063] Component A is obtained by mixing 2,6-di-tert-butyl-p-cresol and base oil in a weight ratio of 1:10-15;

[0064] Component B is obtained by ...

Embodiment 2

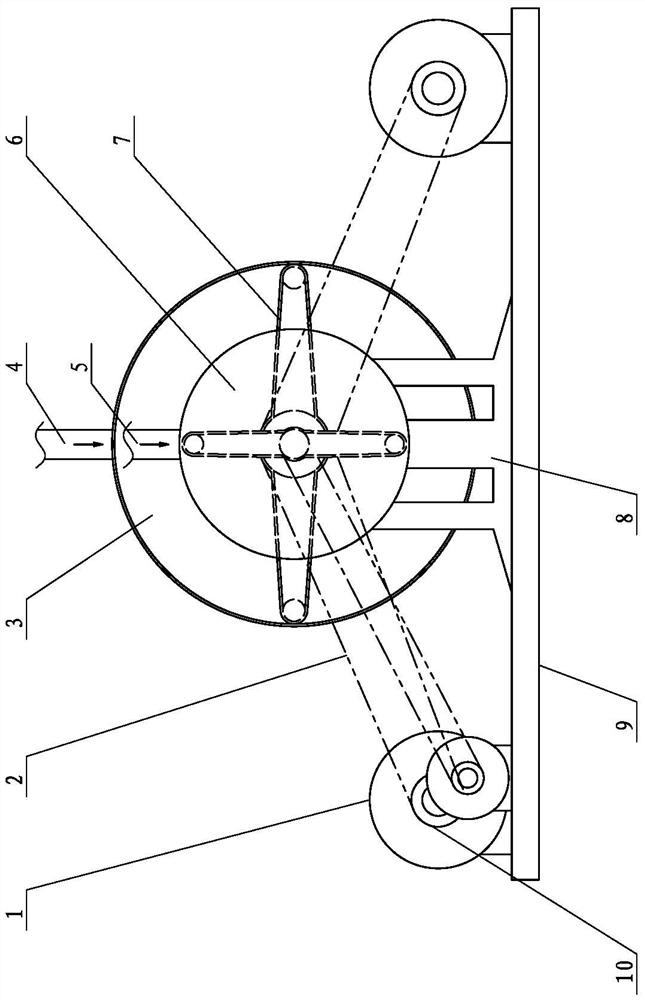

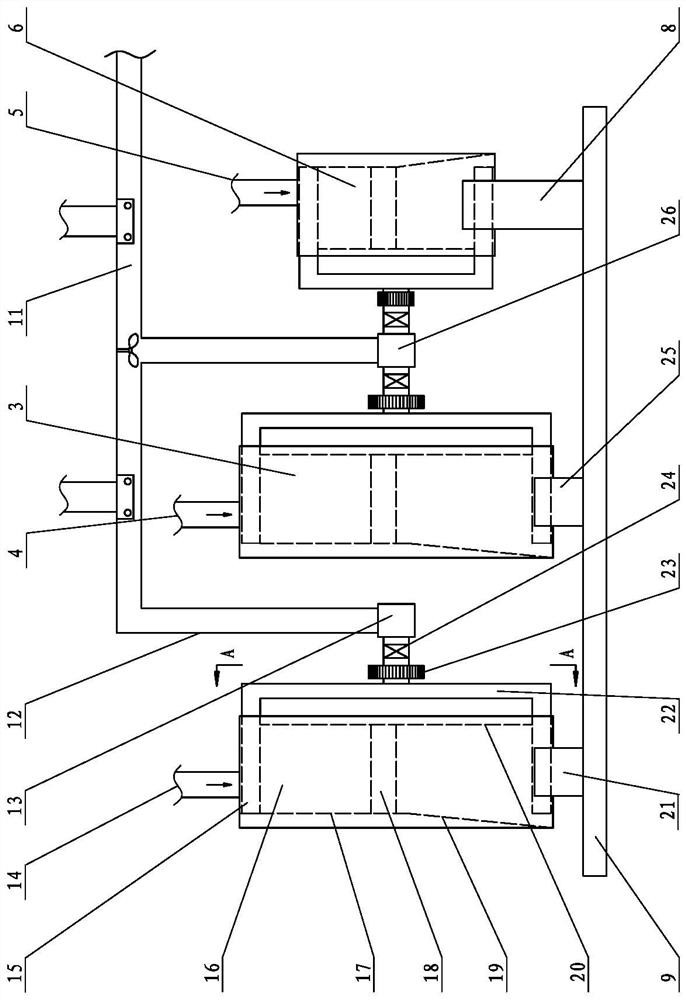

[0071] like Figure 1-5 As shown, the online blending and filling equipment includes a quantitative pre-mixing device, a nitrogen-added pulse blending device, and a suction-type replacement device, and the quantitative pre-mixing device, the nitrogen-added pulse blending device, and the suction-type replacement device are from front to back. Sequential connection settings.

[0072] like figure 1 and 2 As shown, the online blending and filling equipment includes a support base, on which a first silo, a second silo and a third silo are sequentially supported by a first support frame, a second support frame and a third support frame. ; The first, second and third silos are all hollow cylindrical silos; a first feeding pipe, a first feeding pipe, a The second feeding tube and the third feeding tube.

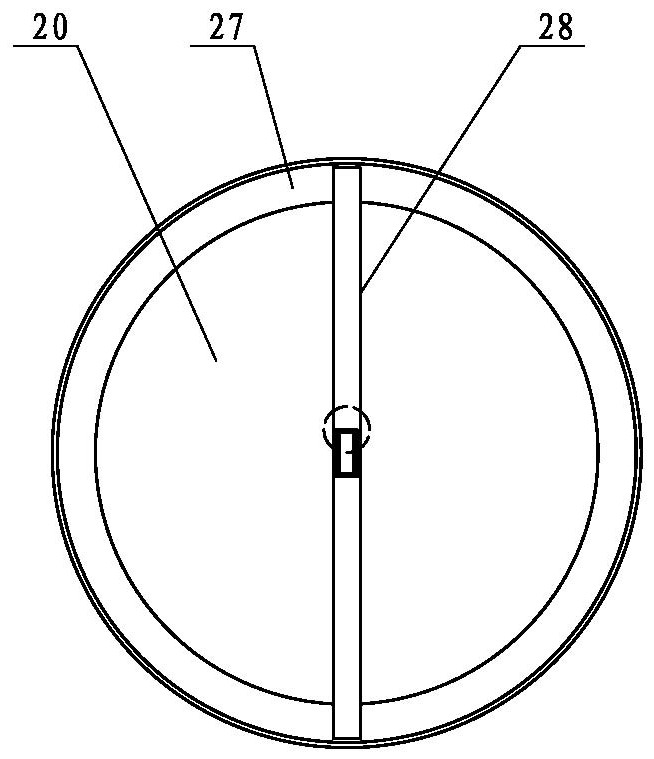

[0073] The first silo, the second silo and the third silo all include a homogeneous material absorbing function silo body, and the homogeneous material absorbing function silo bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com