Pyrolysis raw gas high-temperature efficient dust removal method

A raw gas, high temperature technology, applied in the direction of gas dust removal, removal of gas pollutants, combustible gas purification, etc., can solve the problems that affect the service life of the dust removal device, blockage of equipment and pipelines, complex composition of crude gas, etc., to reduce Safe production risk, super long service life, and the effect of improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be described in further detail below in conjunction with the accompanying drawings.

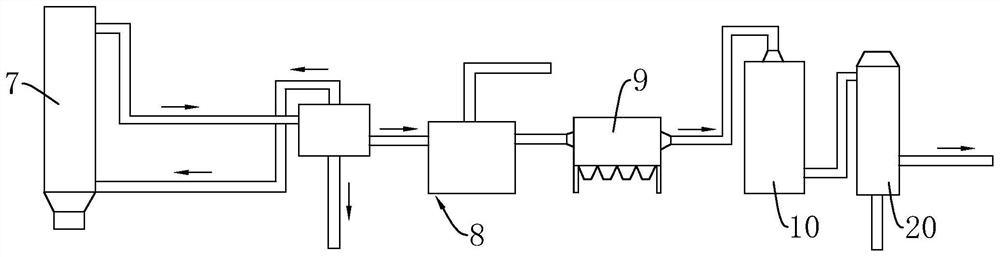

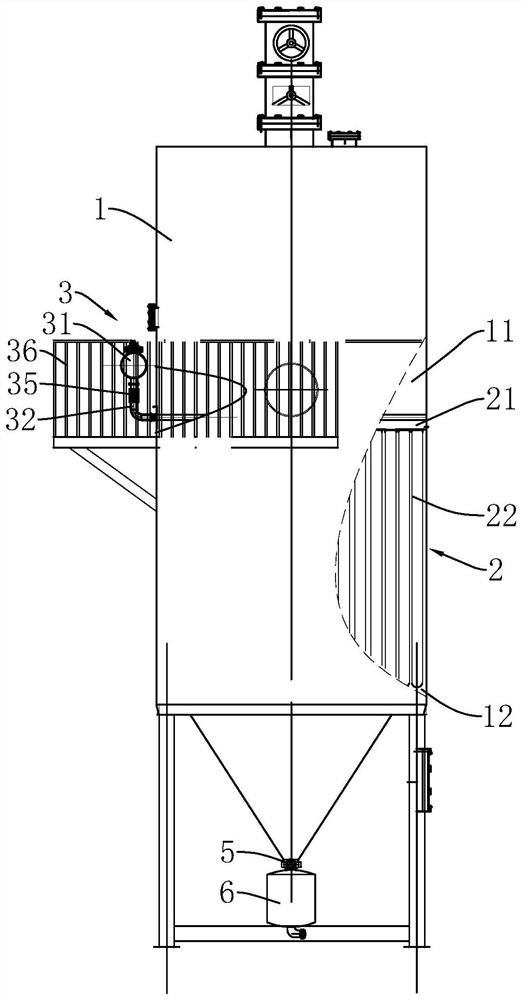

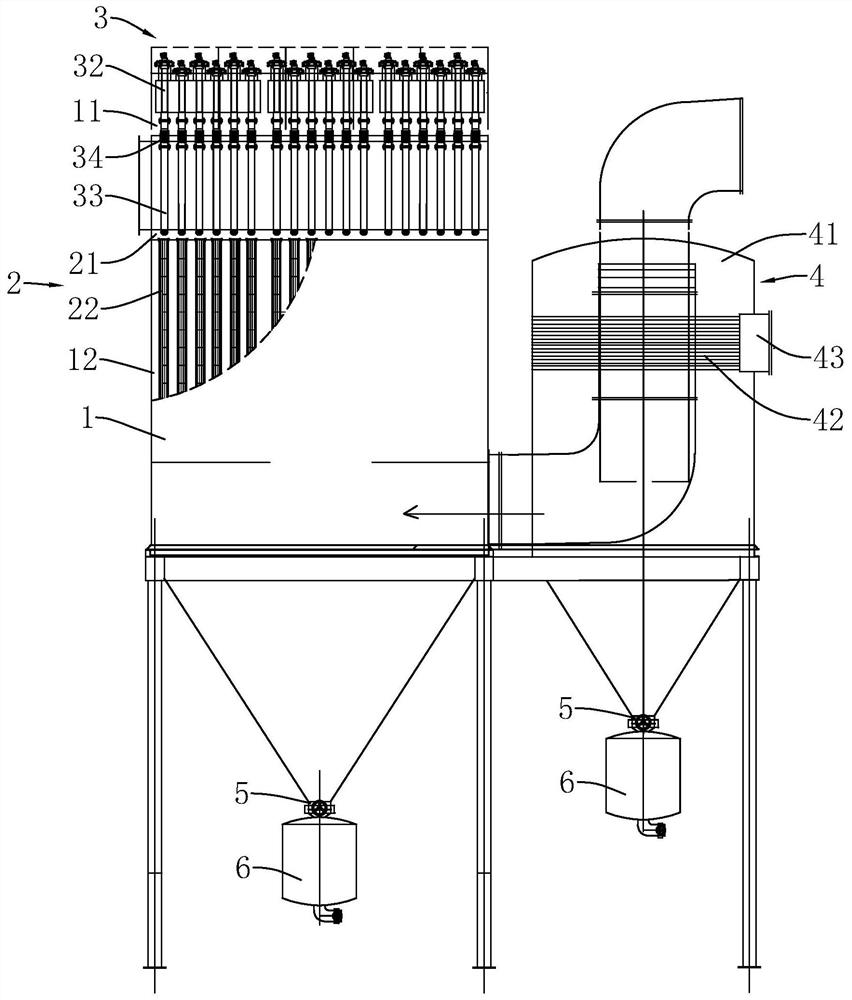

[0040] The embodiment of this application discloses a high-temperature, high-efficiency, explosion-proof integrated modular dust removal equipment for pyrolysis crude gas, such as figure 2 , image 3 As shown, the pyrolysis crude gas high-temperature, high-efficiency, explosion-proof integrated modular dust removal equipment includes a casing 1, a high-temperature ceramic filter system 2, a high-pressure backflushing system 3, and a pre-dust removal system 4.

[0041] Wherein, the inside of the casing 1 has a chamber that allows the medium to flow in or out, and the outer side of the casing 1 is provided with an air inlet and an air outlet communicating with the chamber, and the air outlet is relatively located above the air inlet. The exterior of the casing 1 is covered with a thermal insulation layer, which is used to reduce the interaction between the high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com