Electric motorcycle part polishing and grinding device

An electric motorcycle, polishing and grinding technology, applied in the direction of grinding drive device, grinding machine tool parts, grinding/polishing equipment, etc., can solve the problems of reduced grinding effect, inconvenient replacement, cumbersome loading and unloading of polishing wheels, etc., and achieve the goal of grinding Increased area, easy replacement, and improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

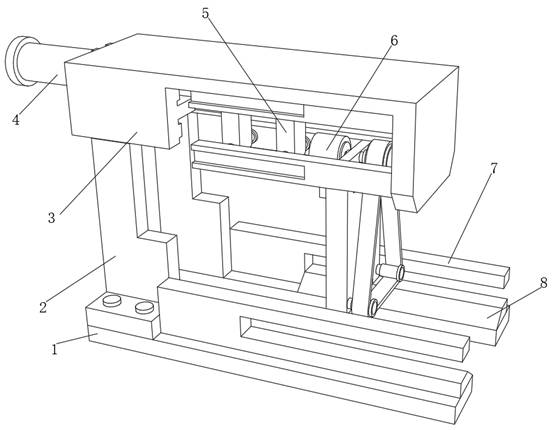

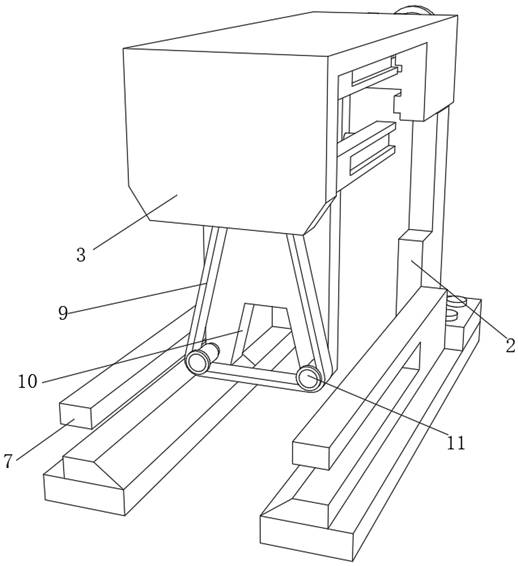

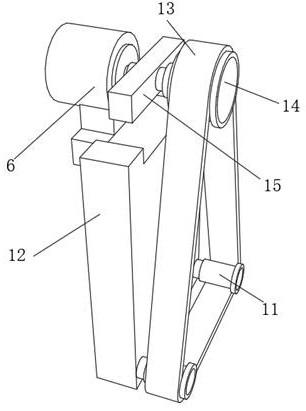

[0031] A polishing and grinding device for electric motorcycle parts, such as Figure 1-4 As shown, the base 1 is included, and the outer walls on both sides of the top of the base 1 are respectively fixed with limit rods 7 by bolts, and the outer walls on one side of the two limit rods 7 are provided with card slots, and the two card slots on the opposite side The structure on one side of the bottom is a fixed slope 8, and the outer wall on the other side of the top of the base 1 is respectively fixed with two support plates 2 by bolts, and the top outer walls of the two support plates 2 are fixed with the same top seat 3 by bolts. The outer wall of one side of the seat 3 is fixed with a hydraulic cylinder 4 by bolts, the outer wall of the bottom of the top seat 3 is provided with an L-shaped guide mechanism 5, and the bottom output end of the L-shaped guide mechanism 5 is provided with a grinding mechanism 9, and the output end of the grinding mechanism 9 is set. A polishing...

Embodiment 2

[0036] A polishing and grinding device for electric motorcycle parts, such as Figure 5 As shown, in order to improve the grinding efficiency of the grinding belt 13; this embodiment makes the following improvements on the basis of embodiment 1: the outer surface of the grinding belt 13 has installation grooves distributed equidistantly, and the bottom of each installation groove Crescent friction strips 25 are clamped on the inner walls, and each crescent friction strip 25 bottom outer wall is provided with card protrusions 27, and one side of the crescent friction strip 25 is provided with three clamping holes 26, and the outer walls of both sides of the crescent friction strip 25 are glued respectively. Arc spacer 24 is connected, and the bottom outer wall of each mounting groove is all provided with limiting groove, and the inner walls of both sides of the mounting groove are welded with three spring columns, and the spring columns are compatible with the clamping hole 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com