Civil engineering construction waste treatment device

A construction waste and processing device technology, applied in construction waste recycling, grain processing, transportation and packaging, etc., can solve problems such as dust pollution, affecting the normal operation of waste processing devices, and low transfer efficiency of broken materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the content of the present invention is further clearly described below in conjunction with the examples, but the protection content of the present invention is not limited to the following examples. In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details.

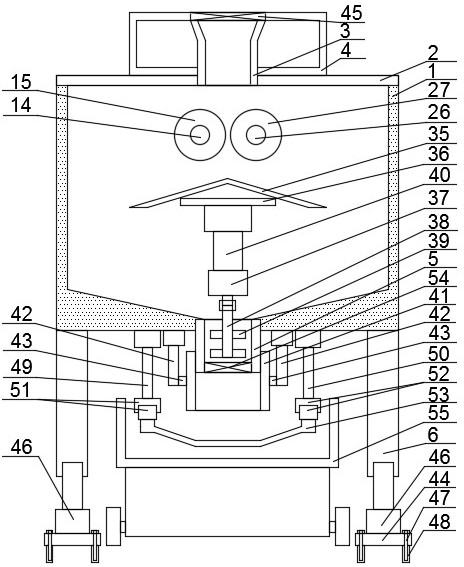

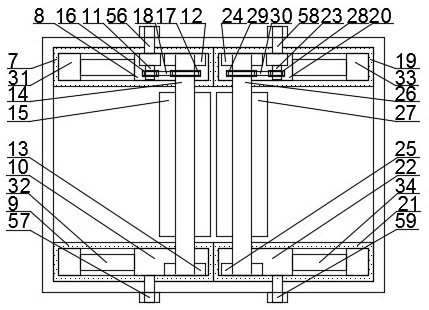

[0029] Such as Figure 1-5 As shown, a civil engineering construction waste treatment device includes a crushing module and a discharge auxiliary module adapted to the crushing module;

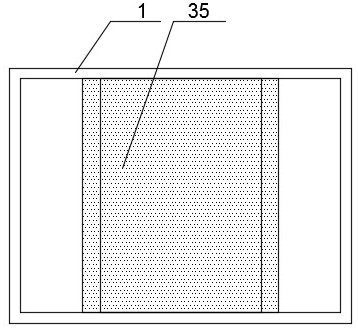

[0030] The crushing module comprises a box body 1, a cover body 2 arranged on the top of the box body 1, a feed hopper 3 arranged on the cover body 2, an anti The dust cover 4, the feed through hole arranged on the dust cover 4 and adapted to the feed hopper 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com