Ultra-high molecular weight polyethylene fiber varicose veins sock and production equipment thereof

A polyethylene fiber and ultra-high polymer technology, which is applied in the directions of processing textile material equipment configuration, yarn, processing textile material cleaning device, etc., can solve the problems of difficulty in ensuring smooth blood, low dyeing efficiency, poor dyeing quality, etc., and achieves a simple structure. , Reasonable design, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

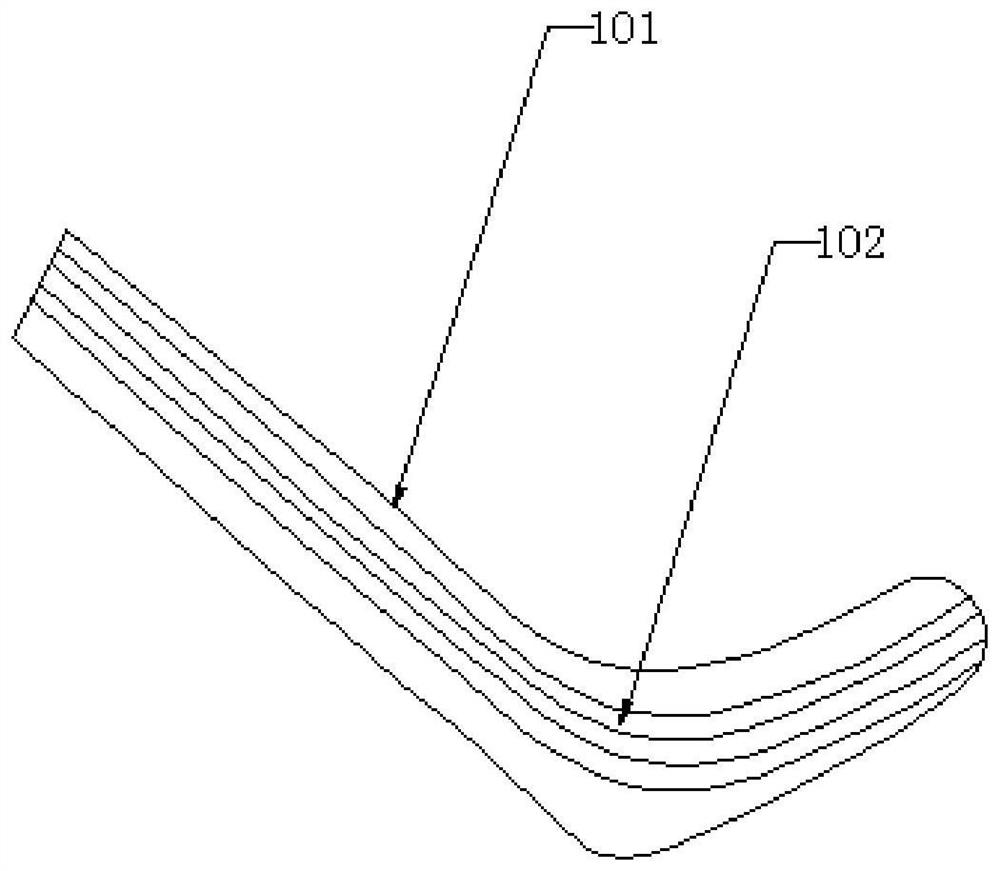

[0037] Such as figure 1 As shown, the present invention discloses a varicose vein socks made of ultra-high molecular polyethylene fiber, which includes a sock body 101, the sock body 101 is composed of an outer layer fabric with a weight fraction of 45% to 55% and an inner layer with a weight fraction of 45% to 55%. Fabric composition, in a specific embodiment of the present invention, the material of the outer layer fabric is woven from yarn, and the yarn is made of raw materials with the following weight fractions: 45 parts of kapok fiber, 45 parts of cotton fiber, and 2 parts of softening agent , 4 parts of dispersant, 90 parts of water; the inner layer fabric is woven with 75% to 80% inner layer yarn and 25% to 30% nano silver-plated fiber by weight fraction, and the inner layer yarn is made of the following weight Fractional raw materials: 15 parts of spandex, 25 parts of kapok fiber, 25 parts of cotton fiber, 15 parts of zinc oxide / gelatin / polyvinyl alcohol composite ant...

Embodiment 2

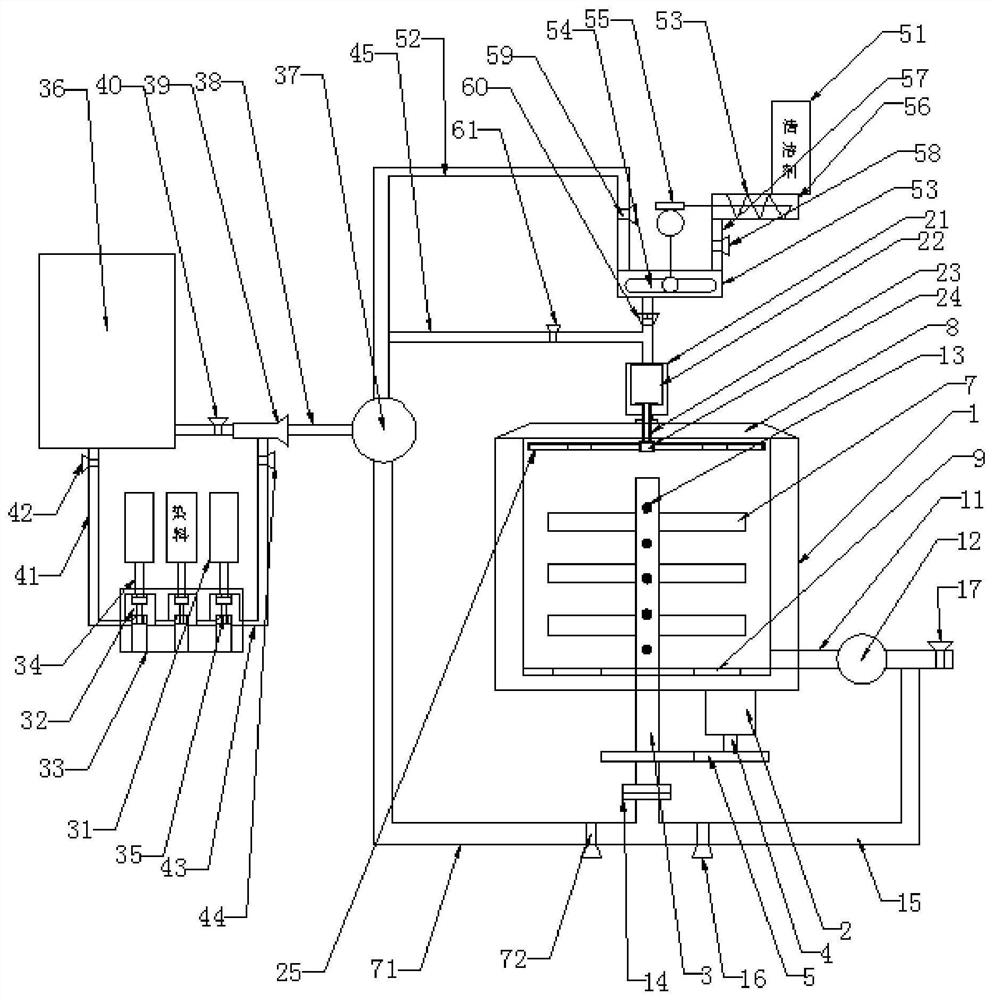

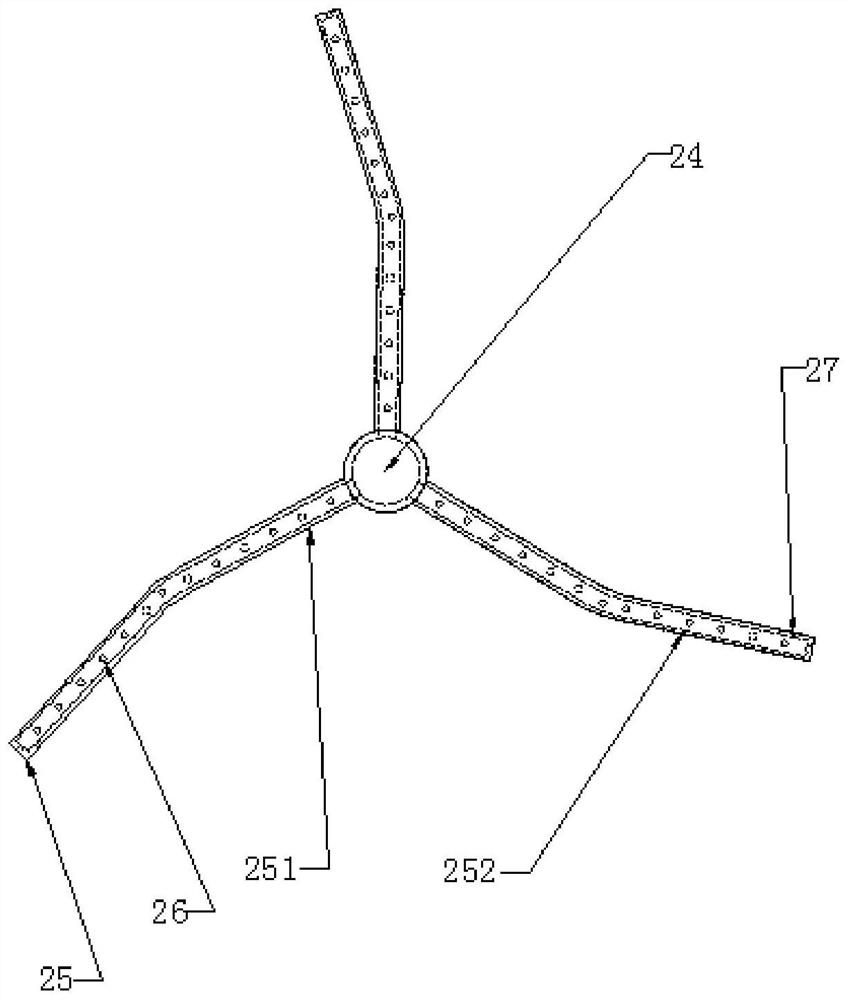

[0042] Such as figure 2 As shown, the present invention simultaneously discloses a production equipment for ultra-high molecular weight polyethylene fiber varicose socks, including a dyeing cylinder 1. In a specific embodiment of the present invention, a stirring assembly is arranged in the dyeing cylinder 1, so that The stirring assembly includes a stirring motor 2 and a stirring rotating shaft 3, the stirring motor 2 is arranged at the bottom of the dyeing vat 1 and the output end is connected with a vertical rotating shaft 4, the lower end of the vertical rotating shaft 4 is provided with a driving toothed disc 5, the The side wall of the stirring shaft 3 is provided with a driven toothed disc 6 that is compatible with the driving toothed disc 5. The upper end of the stirring shaft 3 runs through the inner bottom of the dyeing vat 1 and then extends to the inside of the dyeing vat body 1. The side of the stirring shaft 3 The wall is provided with a number of stirring blade...

Embodiment 3

[0049] Such as Figure 2-Figure 3 , the difference from Embodiment 2 is that, in a specific embodiment of the present invention, the lower cleaning agent pipe 57 is provided with a third washing control valve 58 electrically connected to the plc controller.

[0050] By adopting the above technical scheme, after the full cleaning is completed, the circulation pump 12 keeps running, the waste dye valve 17 is opened, and the waste water is discharged, and during the discharge process, the plc controller controls the switching of the second washing control valve 61 on the water pipe 45 To the open state, the first washing control valve 59 switches to the closed state, and stops sending clean water. At this time, the water directly enters the inner cavity 22 through the water pipe 46, and the left and right sides of the one-way valve 60 will not refill the cleaning agent. In the mixing box 53, switch to the function of washing and dyeing the inside of the vat 1 at this moment, full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com