Volatile oil spray grinding inclusion equipment

A technology for volatile oil and equipment, applied in the field of volatile oil spray grinding inclusion equipment, can solve the problems of fine particle size of inclusion compounds, low inclusion rate, large loss, etc., achieve fine and uniform droplets, improve inclusion rate, structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

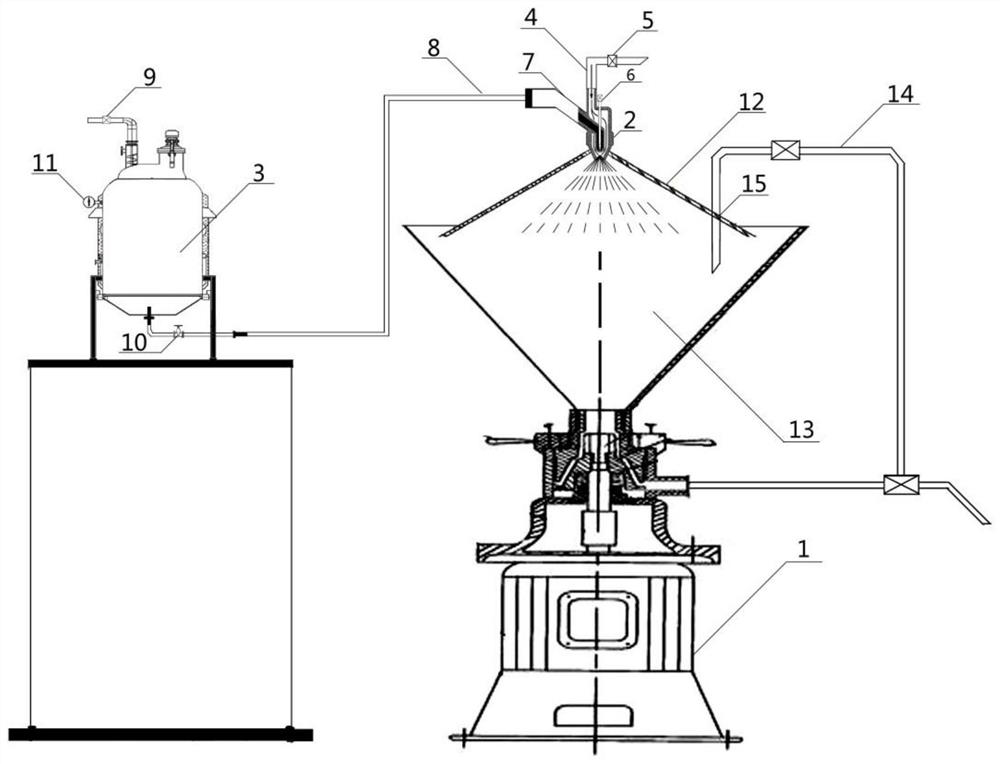

[0032] Embodiment 1 The structure and operation mode of the volatile oil spray grinding inclusion equipment

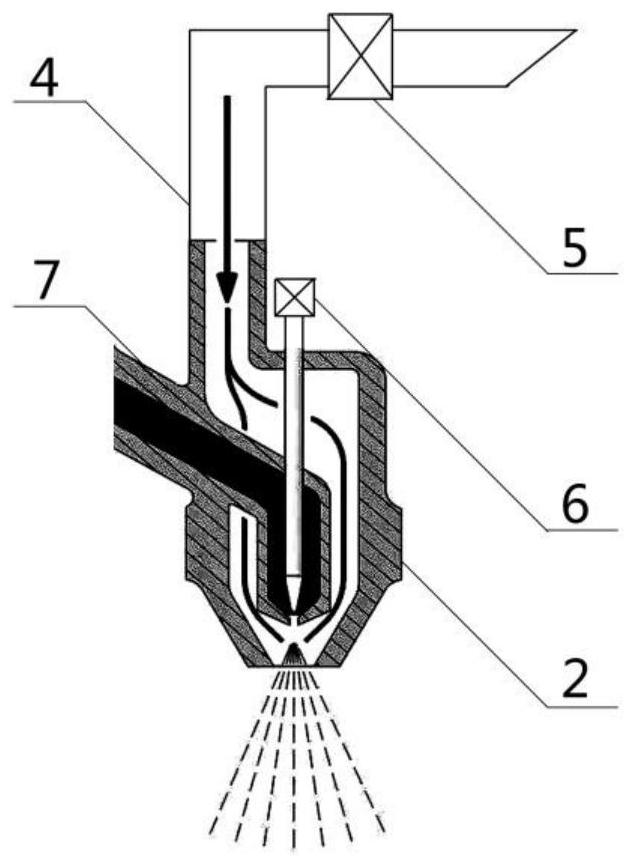

[0033] as attached figure 1 As shown, the volatile oil spray grinding inclusion equipment of the present invention is mainly composed of a colloid mill 1, a high-efficiency atomization nozzle 2 and a pressure-bearing liquid material tank 3. There is a high-efficiency atomizing nozzle 2; at the same time, the pressure-bearing liquid material tank 3 is in communication with the liquid inlet pipe 7 of the high-efficiency atomizing nozzle 2 through a liquid material pipe 8.

[0034] An air pressure conduit 4 is arranged on the upper part of the high-efficiency atomizing nozzle 2, and a first air pressure regulating valve 5 is arranged on the air pressure conduit 4. The middle part of the high-efficiency atomizing nozzle 2 is provided with an electromagnetic flow regulating valve 6, and the spraying frequency, spraying time and atomization degree of the high-efficiency ato...

Embodiment 2

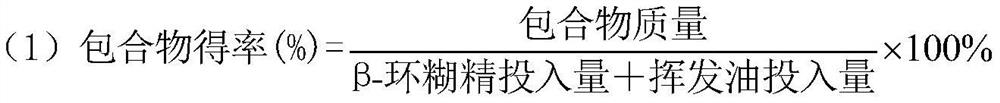

[0038] Example 2 Research on the inclusion rate and yield of chaiyin particle volatile oil grinding clathrate

[0039] 1 material

[0040] 1.1 Instruments TCS-30 electronic platform scale (Mettler-Toledo), QT-2 straight multifunctional extraction tank (Shanghai Yuanyue Pharmaceutical Machinery Co., Ltd.), BJG-60 electric heating and stirring insulation tank (Wenzhou Pharmaceutical Equipment Factory), SHB-B95 circulating water multi-purpose vacuum pump (Zhengzhou Great Wall Technology Industry and Trade Co., Ltd.), GZX-9240MBE electric heating constant temperature blast drying oven (Shanghai Boxun Industrial Co., Ltd. Medical Equipment Factory), JM50AL colloid mill (Wenzhou colloid mill factory), SD600 three-legged hanging bag centrifuge (Zhangjiagang Gaohong Centrifuge Manufacturing Co., Ltd.), XS204 electronic analytical balance (Mettler-Toledo).

[0041] 1.2 Reagents and drugs β-cyclodextrin (Mengzhou Huaxing Biochemical Co., Ltd., batch number: 20190201); Bupleurum, honeys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com