Method for preparing preserved vegetables

A technology of dried plum vegetables and dried vegetables, which is applied in the field of preparing dried plum vegetables, can solve the problems of long production cycle and increase fragrance, and achieve the effect of shortening the pickling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

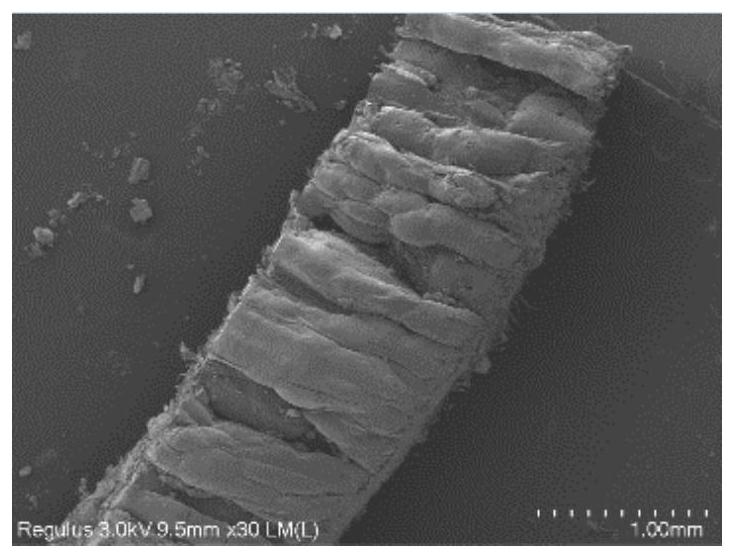

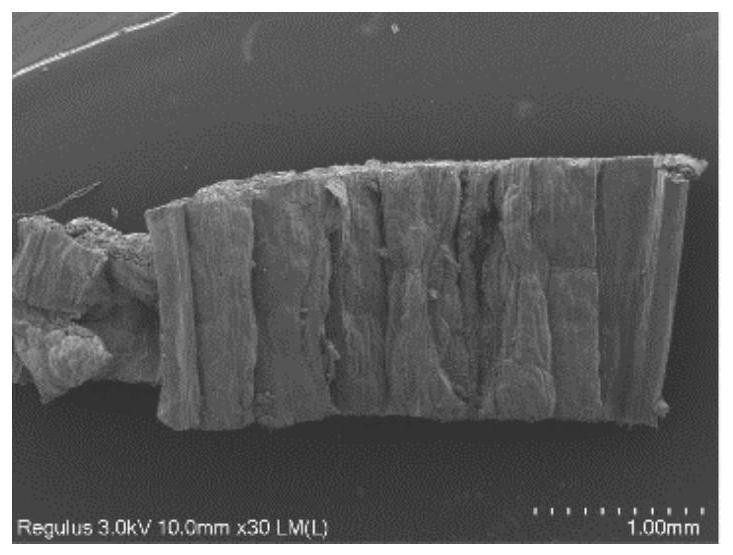

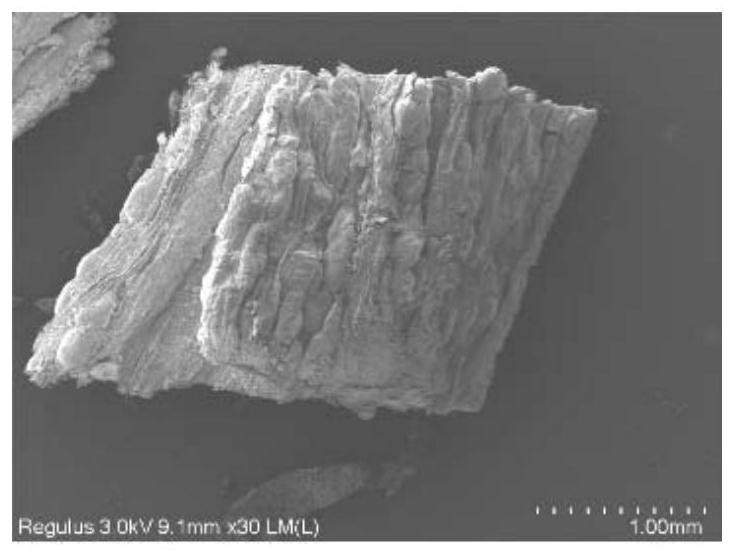

Image

Examples

Embodiment 1

[0033] A kind of method that is suitable for large-scale prunes production, comprises the following steps:

[0034] (1) Select potherb mustard from the natural limit of 130 days in Zhejiang area and harvested from the whole plant as raw material;

[0035] (2) Use 10 times the volume of water to wash the potherb mustard raw materials, add edible salt according to the ratio of 3kg of salt per 100kg of fresh vegetables, stir evenly, add vegetables in layers, fill them into containers in a solid manner, and marinate after solidification After 8 days of preparation, it was cut into 1.0 cm length vegetable segments.

[0036] (4) After putting the processed vegetables into the puffing tank, the temperature of the puffing tank is 120°C and the pressure is 1.0 MPa. After keeping it for 15 minutes, open the valves of the puffing tank and the vacuum tank, release the pressure instantly, and repeat puffing twice.

[0037] (5) Steam the puffed sample in an atmospheric steamer, and continu...

Embodiment 2

[0043] The method for producing prunes with reference to Example 1 differs only in that the pressure of the expansion tank is adjusted to 0.2MPa, 0.5MPa, 1.0MPa, 1.5MPa and 2.0MPa, and other conditions are the same as in Example 1.

[0044] Table 1 Effects of different puffing pressures on the volatile components of prunes

[0045]

[0046] It can be seen from the above Table 1 that with the increase of the puffing pressure, the volatile components gradually increase; but when the puffing pressure exceeds 1.5 MPa, the amount of the volatile components does not increase significantly. The browning index and the amount of intermediate products of Maillard reaction also increased with the increase of puffing pressure. Since the material is segmented and thin and the resulting product requires moderate chewiness, 0.5-1.5 MPa is selected as the appropriate puffing pressure to promote the release of the volatile components of the sample and the progress of the Maillard reaction. ...

Embodiment 3

[0048]Refer to the method of Example 1 to produce prunes, the only difference is that the temperature of the expansion tank is adjusted to 60°C, 80°C, 100°C, 120°C and 140°C, and other conditions are the same as in Example 1.

[0049] Table 2 Effects of different puffing temperatures on the volatile components of prunes

[0050]

[0051] It can be seen from the above Table 2 that with the increase of the puffing temperature, the volatile components gradually increase; but when the puffing temperature exceeds 120°C, the amount of the volatile components does not increase significantly. The browning index and the amount of intermediate products of Maillard reaction also increased with the increase of puffing pressure. Since the material is segmented and thin and the resulting product requires moderate chewiness, 80-120°C is selected as the appropriate puffing temperature to promote the release of the volatile components of the sample and the progress of the Maillard reaction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com