Silver carp dried meat slice processing technology

A processing technology, the technology of silver carp meat, applied in the field of silver carp jerky processing technology, can solve the problems of rare leisure fish products, low processing ratio, insufficient freshwater products, etc., achieve the prediction of deodorization effect, high accuracy, and optimize the processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

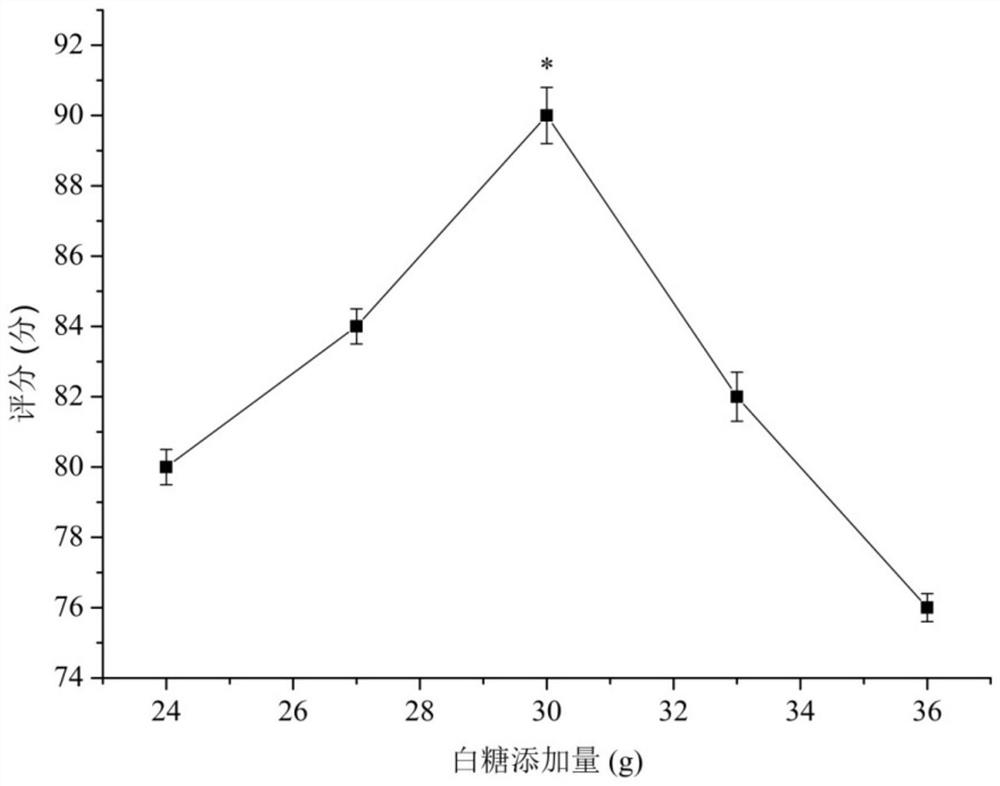

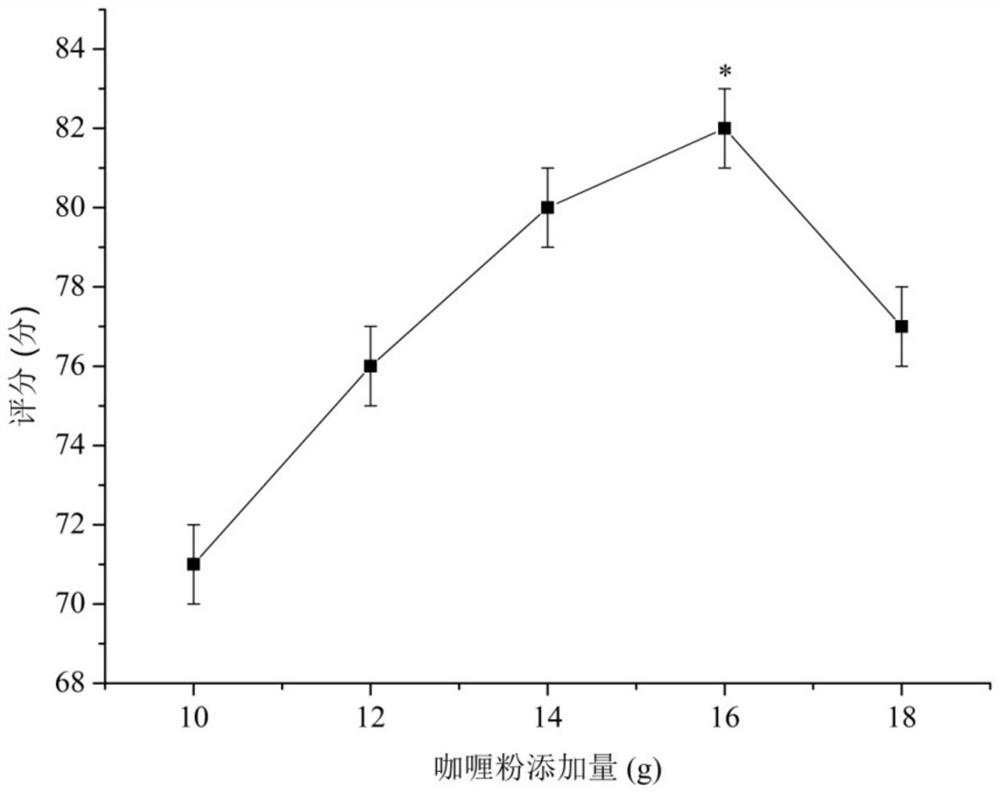

[0059] Optimization of the basic formula of curry-flavored dried fish:

[0060] Using crushed surimi as the main raw material, and under the same conditions as other treatments, the effects of salt, sugar, curry powder, and soy sauce on the sensory quality of dried fish were analyzed.

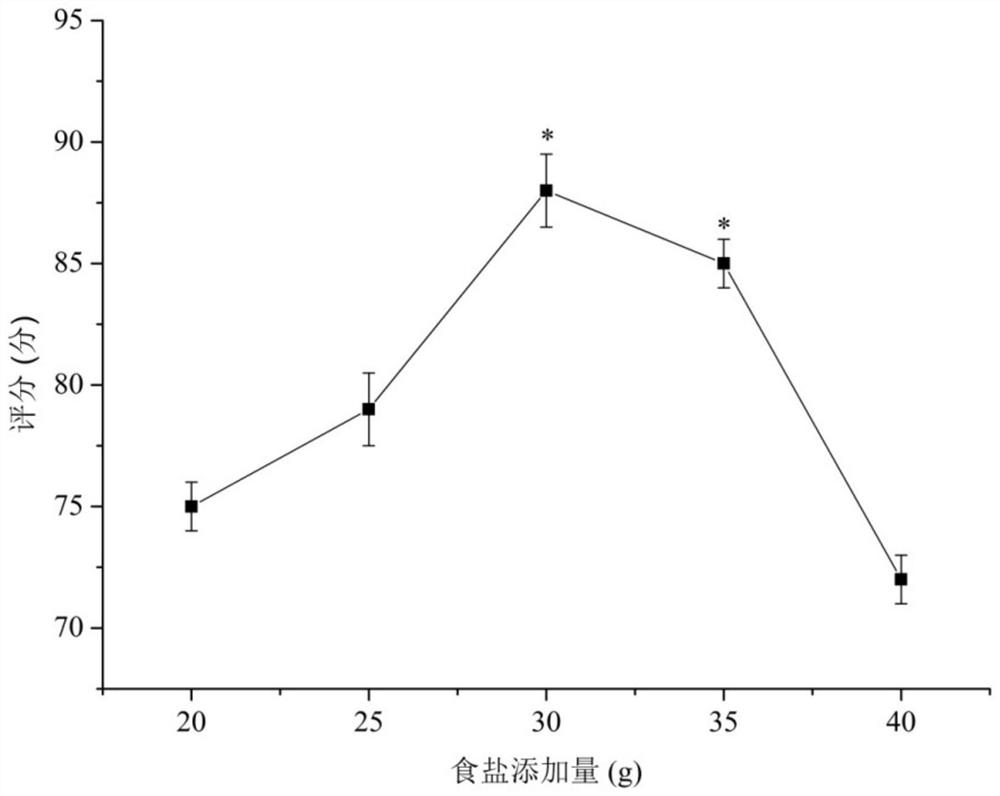

[0061] (1) The effect of salt addition on the sensory quality of dried fish:

[0062] When adding 30g of sugar, 18g of soy sauce, and 14g of curry powder to 1kg of surimi, the amount of salt added was 20g, 25g, 30g, 35g, and 40g, respectively, and the sensory evaluation was carried out for the dried fish under different amounts of salt;

[0063] Depend on figure 1 As shown, when the salt addition is in the range of 20-30g / kg, with the increase of salt addition, the sensory score of dried fish increases; when the salt addition is 30g / kg, the sensory score of dried fish increases significantly (P<0.5); when the salt addition was higher than 30g / kg, with the increase of salt addition, the sensor...

Embodiment 2

[0082] Research on deodorization process of fish meat:

[0083] (1) Single factor experiment of fish deodorization treatment:

[0084] ① Effect of soaking material-liquid ratio on deodorization of fish meat:

[0085] The fish is soaked in salt water for 30 minutes, and the salt concentration of the soaking liquid is 6%. When soaking, the ratio of material to liquid was set to 1:1, 1:2, 1:3, and then after rinsing, crushing, spreading, baking, and cooking, the deodorization effects of fish under different ratios of material to liquid are shown in Table 4 , sensory evaluation is carried out on the fish meat under different material-to-liquid ratios, and a better level of deodorization is selected;

[0086] Table 4 Fish meat deodorization effect under different material-to-liquid ratios

[0087]

[0088]It can be seen from Table 4 that when the ratio of material to liquid for soaking fish meat is 1:1, the taste of dried fish meat is the worst, the taste is bad and the fishy...

Embodiment 3

[0112] Research on vacuum frying and drying process of dried fish meat:

[0113] (1) Effect of frying temperature on product quality:

[0114] Set the vacuum degree to 0.09MPa, fry for 50s, and fry at temperatures of 85°C, 95°C, 105°C, 115°C, and 125°C, record the sensory evaluation of the product, and study the effect of frying temperature on the quality of dried fish;

[0115] Depend on Figure 5 It can be seen that when the frying time is 50s, the vacuum degree is 0.09MPa, and the frying temperature is 105°C, the sensory score of dried fish meat is the highest, which is 86 points. When the frying temperature is lower than 105℃, the quality of dried fish meat increases with the increase of temperature; when the frying temperature is higher than 105℃, the quality of dried fish meat decreases with the increase of temperature. This may be due to the low temperature and slow evaporation of dried fish meat, resulting in high moisture content and reduced quality of the product; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com