PCB production device and production equipment

A production device, first-class technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problem of large PCB production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

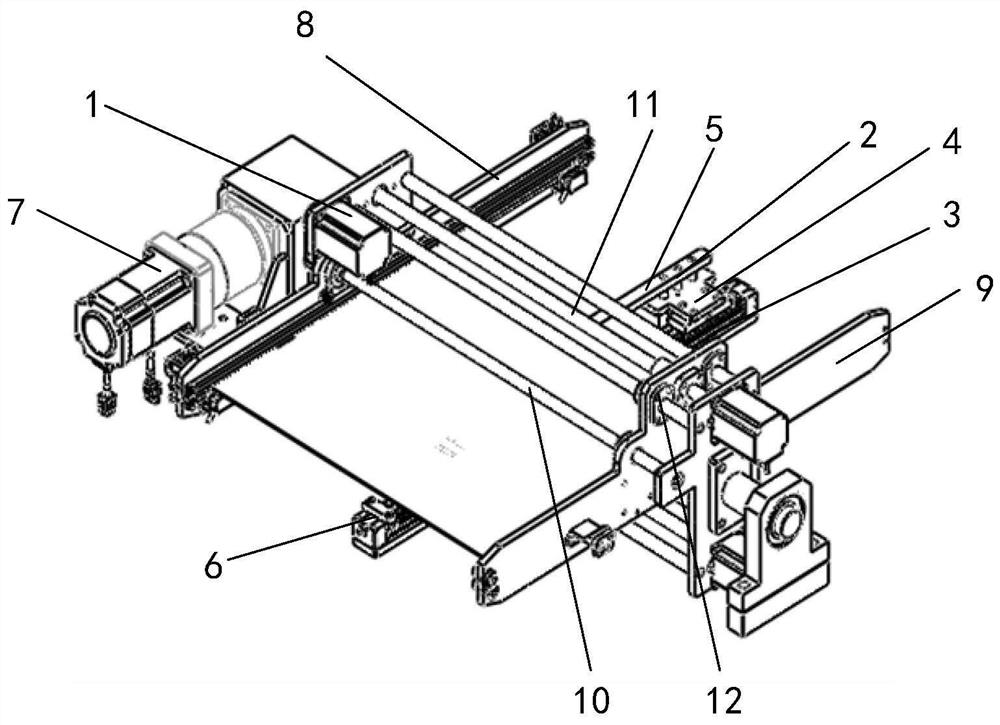

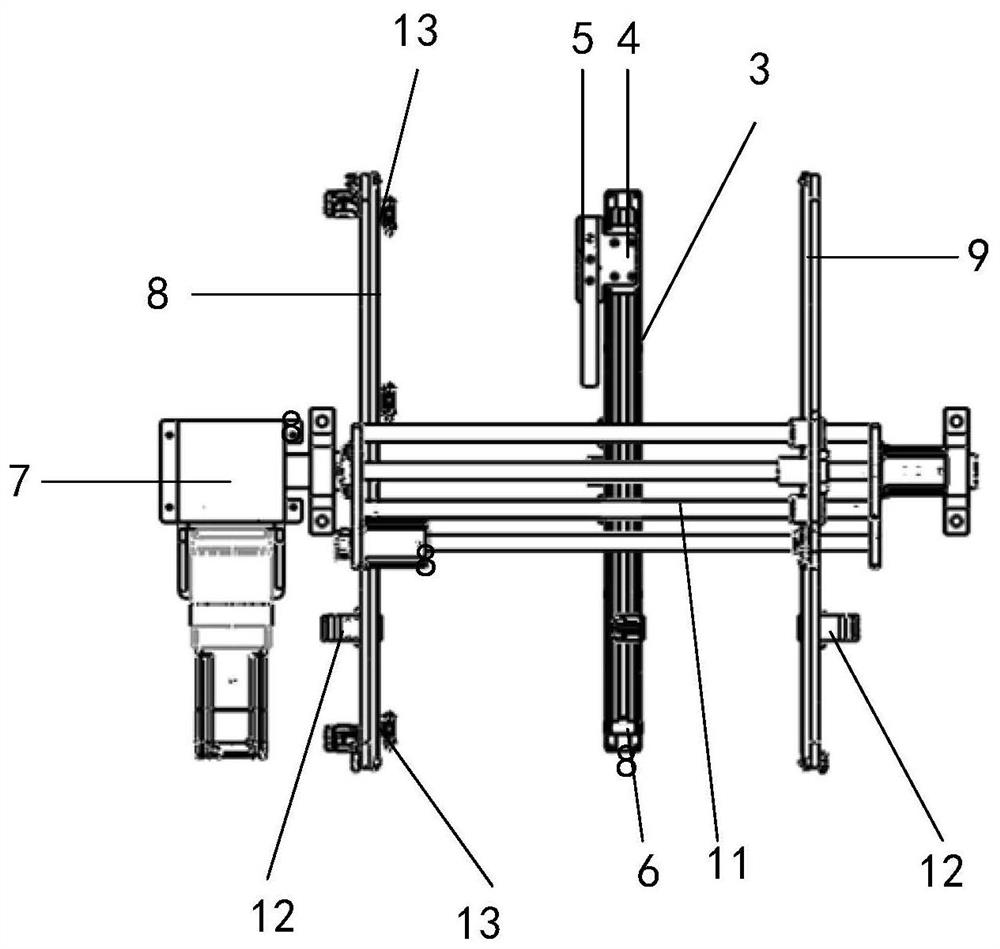

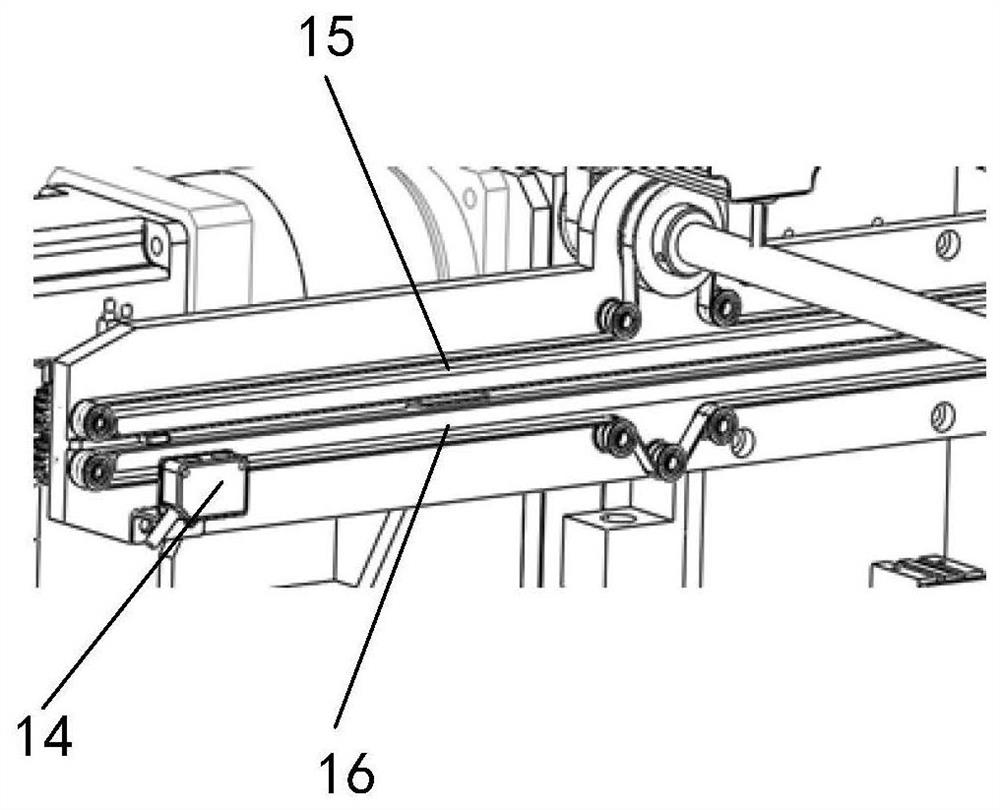

[0036] Such as figure 1 with figure 2 As shown, a PCB production device provided by an embodiment of the present invention includes a turning mechanism 1 and a push rod mechanism 2 . The turning mechanism 1 carries the PCB processed on one side, and turns the PCB over. After turning over, it can be used for production and processing by the reverse side processing station. The push rod mechanism 2 pushes the PCB in the turning mechanism 1 to make the PCB move out of the turning mechanism 1 . That is, the push rod mechanism 2 pushes the flipped PCB out of the flipping mechanism 1, and the turnover frame takes over the rolled out PCB. After the turnover frame is filled with PCBs, it is transported to the reverse side by an Automated Guided Vehicle (AGV for short) for processing. On the automatic line body of the workstation. Using the PCB production device provided by the embodiment of the present invention, the push rod mechanism 2 can be used to push the PCB in the turnover...

Embodiment 2

[0046] The embodiment of the present invention also provides a production equipment, including the PCB production device provided in Embodiment 1. The production equipment may also include a PCB turnover frame, and the push rod mechanism pushes the PCB in the turning mechanism, so that the PCB moves out of the turning mechanism and enters PCB turnover box. After the PCB turnover box is finished framing, it can be transported by the AGV to the reverse processing station, which avoids occupying a large area of the overall space to set up the double-sided soldering automatic line body. The production equipment using the PCB production device has higher flexibility in the location setting of the processing station, can adapt to different types of production spaces, and improves the applicability of the production equipment. The production equipment provided by the embodiment of this aspect has the same technical features as the PCB production device provided by the above embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com