Aqueous solution type lithium iron phosphate positive electrode adhesive and preparation method and application thereof

A technology of lithium iron phosphate and aqueous solution, which is applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of poor stability, achieve good thermal stability, easy preparation, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

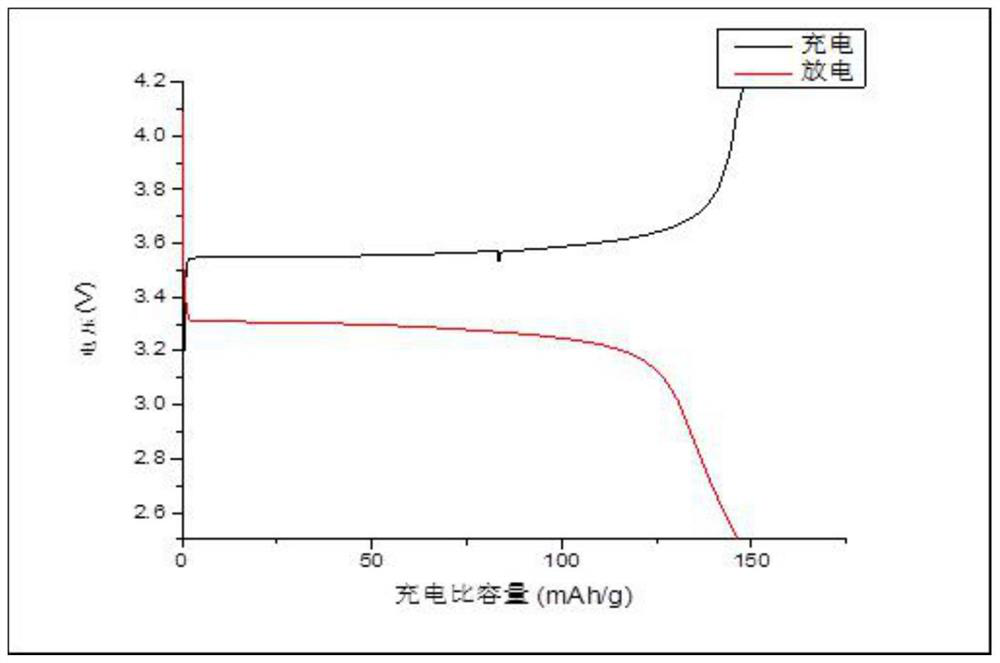

Image

Examples

preparation example Construction

[0061] The application provides a method for preparing an aqueous solution type lithium iron phosphate positive electrode binder, comprising the following steps:

[0062] S101. Put the low-level unsaturated carboxylic acid, the acrylamide and its derivatives, the water-soluble acrylate, and the initiator into the reaction container, and add 300-320 parts of deionized water, and stir until each The material is completely dissolved; the weight of the initiator accounts for 50% to 75% of the total amount of the initiator in the formula;

[0063] S102. Keep stirring, raise the reaction temperature to 55-75°C, and react for 2-6 hours;

[0064] S103. Keep stirring and the reaction temperature, put the (meth)acrylate phosphate and the remaining initiator into the reaction container, and add the deionized water until the theoretical solid content of the reaction solution reaches a preset value , continue to react for 1.5 ~ 4h;

[0065] S104, keep stirring, stop heating, after the te...

preparation Embodiment 1

[0077] Drop into 2-acrylamide-2-methylpropanesulfonic acid 4g, acrylic acid 15g, acrylamide 6g, hydroxyethyl acrylate 12g, ammonium persulfate 0.15g and 300g of deionized water, fully stirred until each material is completely dissolved. Keep stirring, heat up to 60°C, and keep the reaction for 4h. Add 6 g of 2-methyl-2-acrylic acid-2-hydroxyethyl phosphate, 0.07 g of ammonium persulfate and 54 g of deionized water, continue the heat preservation reaction for 2 hours, and stop heating. After the temperature in the three-neck bottle drops to normal temperature, add metered lithium hydroxide, control the pH value of the product to 6-8, and collect the material.

[0078] The product is a light yellow transparent viscous aqueous solution with a viscosity of about 20000cp (25°C). Take a small amount of adhesive and dry it in an oven to obtain a sheet with a length and width of about 10 mm and a thickness of about 3 mm. After immersing the thin slice in the electrolyte and keeping...

preparation Embodiment 2

[0080] Compared with Preparation Example 1, 15 g of acrylic acid was replaced by 12 g of acrylic acid and 3 g of maleic acid, 6 g of acrylamide was replaced by 5 g of acrylamide and 1 g of N-methylol acrylamide, and all hydroxyethyl acrylate was replaced by 3-hydroxyl acrylic acid Propyl ester, all the other are with embodiment 1.

[0081] The product is a light yellow transparent viscous aqueous solution with a viscosity of about 30000cp (25°C). Take a small amount of adhesive and dry it in an oven to obtain a sheet with a length and width of about 10 mm and a thickness of about 3 mm. After immersing the thin slice in the electrolyte and keeping it warm at 60° C. for 72 hours, the volume of the thin slice increases by less than 5%.

[0082] The application provides an application of an aqueous solution-type lithium iron phosphate positive electrode binder, including using the aqueous solution-type lithium iron phosphate positive electrode binder to prepare electrical materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com