Minimum ignition energy testing device

A test device and ignition energy technology, applied in the direction of material explosiveness, can solve the problems of potential safety hazards, inability to effectively seal, and limited test conditions, and achieve a reasonable effect of explosive test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

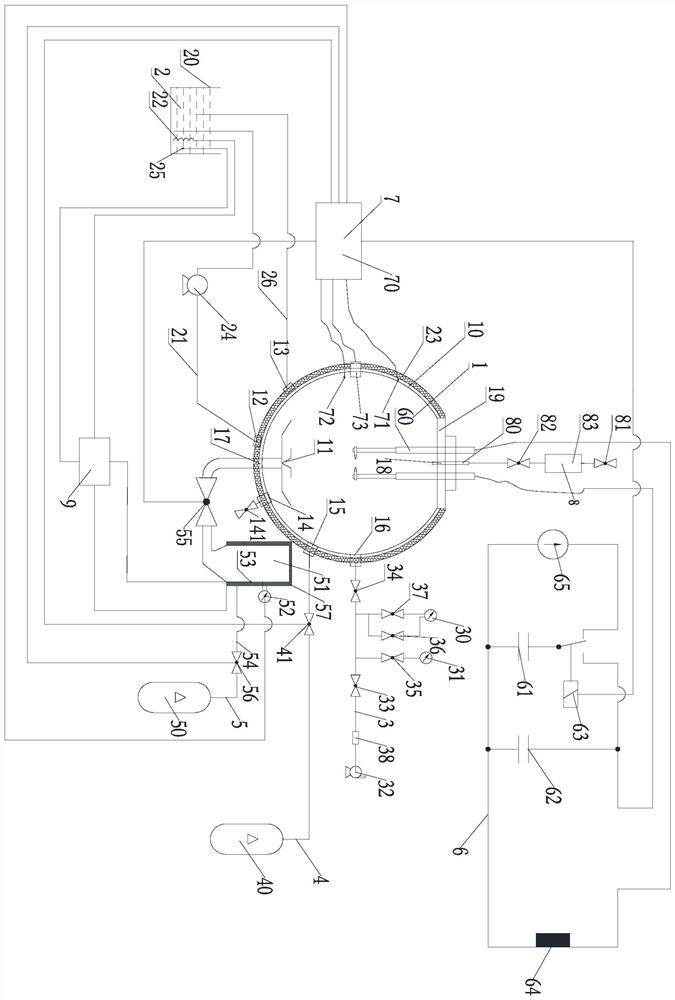

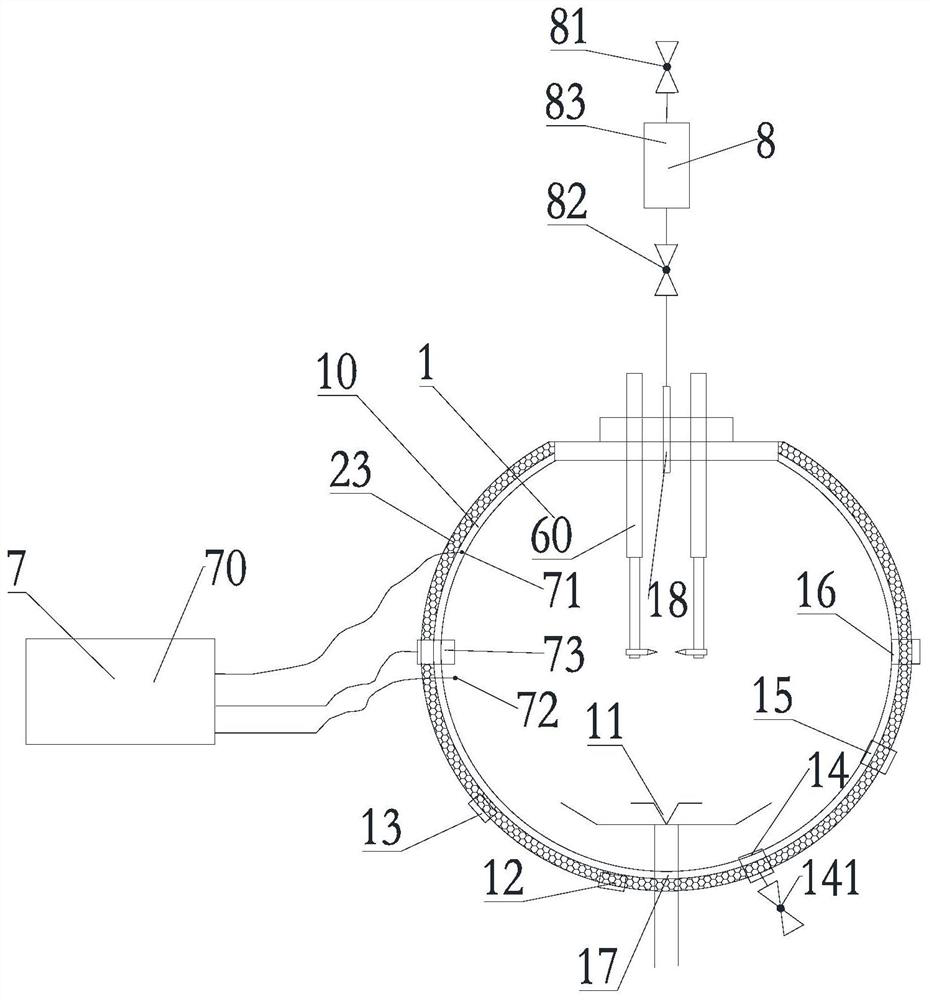

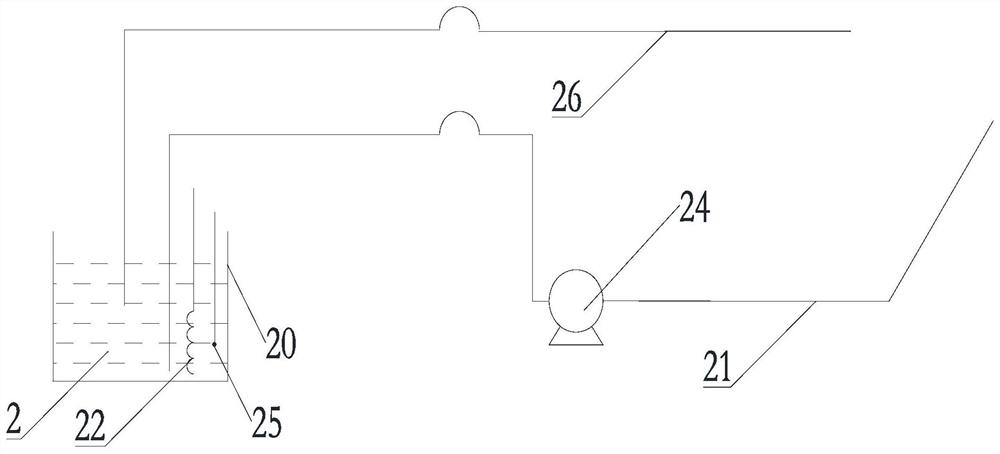

[0032] Such as figure 1As shown, a minimum ignition energy test device includes an explosion chamber 1, a heating system 2, a vacuum system 3, a gas supply system 4, a powder spraying system 5, an ignition system 6, a data acquisition system 7, a controller 9 and a In the sample system 8, the water outlet pipe 26 and the water inlet pipe 21 of the heating system 2 are all connected with the thermal insulation layer 23 of the explosion chamber 1, and the second manual valve 34 of the vacuum system 3 is connected with the air extraction port 16 of the explosion chamber 1 for supplying The first solenoid valve 41 of the gas system 4 is connected with the air inlet 15 of the explosion chamber 1, the second solenoid valve 55 of the powder injection system 5 is connected with the powder inlet 17 of the explosion chamber 1, and the ignition system 6 is connected with the explosion chamber 1. The electrode 60 of 1 is connected, the second temperature sensor 71, the third temperature s...

Embodiment 2

[0051] (1) Preparation before explosion

[0052] Take 500g / m 3 Tobacco dust sample, open the powder bin 51, load the sample, close the screw hatch of the powder bin 51; make sure that the electrode 60 on the sealing cover 19 is connected with the ignition system 6, close the top cover and tighten it. Close the seventh manual valve 82, open the sixth manual valve 81 of the liquid injection port, inject 2mL sample into the transition chamber 83, close the sixth manual valve 81; open the first manual valve 33 and the second manual valve 34, close the third manual valve Valve 35, the fourth manual valve 36, the fifth manual valve 37, open the vacuum pump 32, vacuumize the reactor 10, open the third manual valve 35, observe the reading of the first pressure gauge 31, determine that the pressure in the reactor 10 reaches After -0.094MPa, close the vacuum pump 32 and the first manual valve 33; open the fourth manual valve 36 and the fifth manual valve 37, and after the pointer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com