High-pressure water supply pipe

A high-pressure water supply and water pipe technology, applied in the direction of pipe components, water saving, pipes/pipe joints/fittings, etc., can solve the problems of normal operation of pipes, inability to filter impurities in a concentrated manner, and difficulty in finding the blocked position of water supply pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

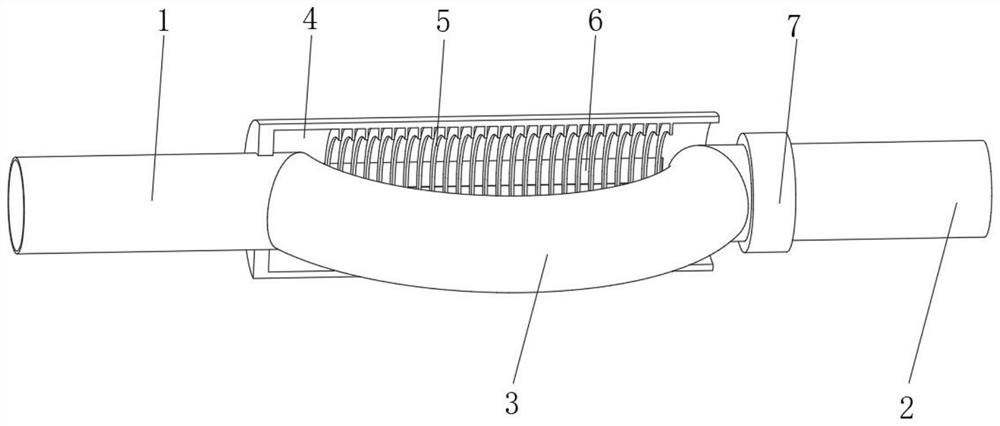

[0037] Such as Figure 1-3 As shown, the present invention provides a technical solution: a high pressure water supply water pipe, including the liquid pipe 1 and the liquid pipe 2, the position of the in-liquid pipe 1 and the liquid pipe 2 has a corrugation mechanism 3, into The liquid tube 1 is outside and close to the corrugated conduction mechanism 3, and the restriction storage frame 4 is fixed, and the internal surface of the restriction storage frame 4 is uniformly fixedly coupled to the restriction clamp 5, and the intermediate position of the internal position inside the storage frame 4 is fixed to the transmission magnet block 6. , The liquid pipe 2 is adjacent to one end of the corrugated conduction mechanism 3 with an active dredge mechanism 7;

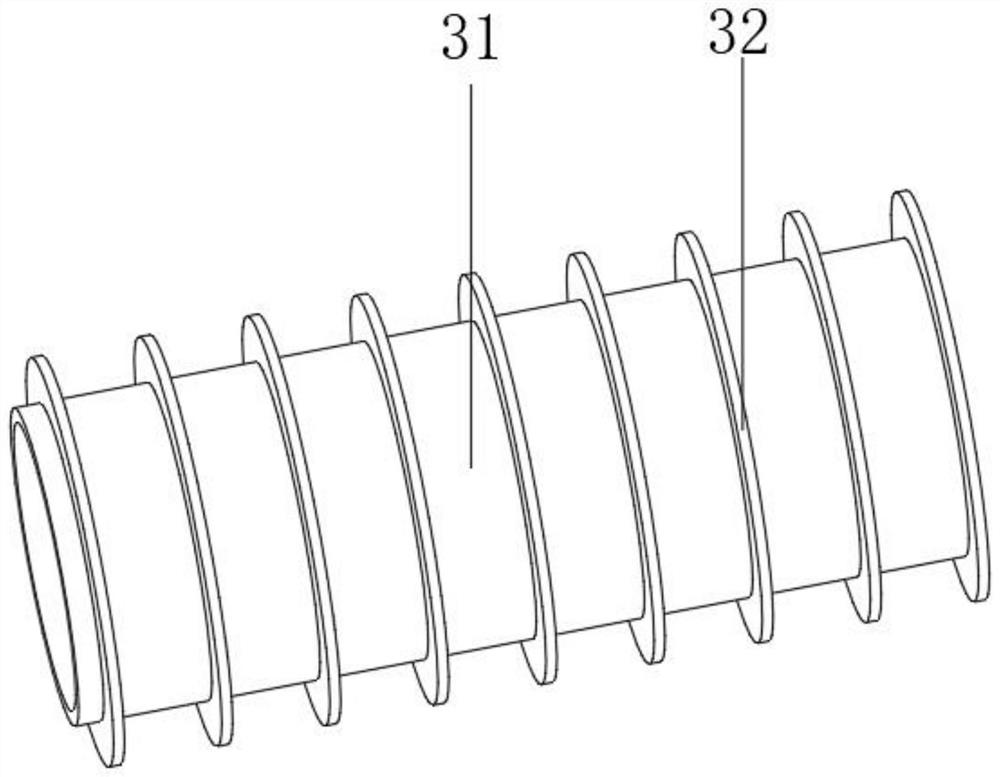

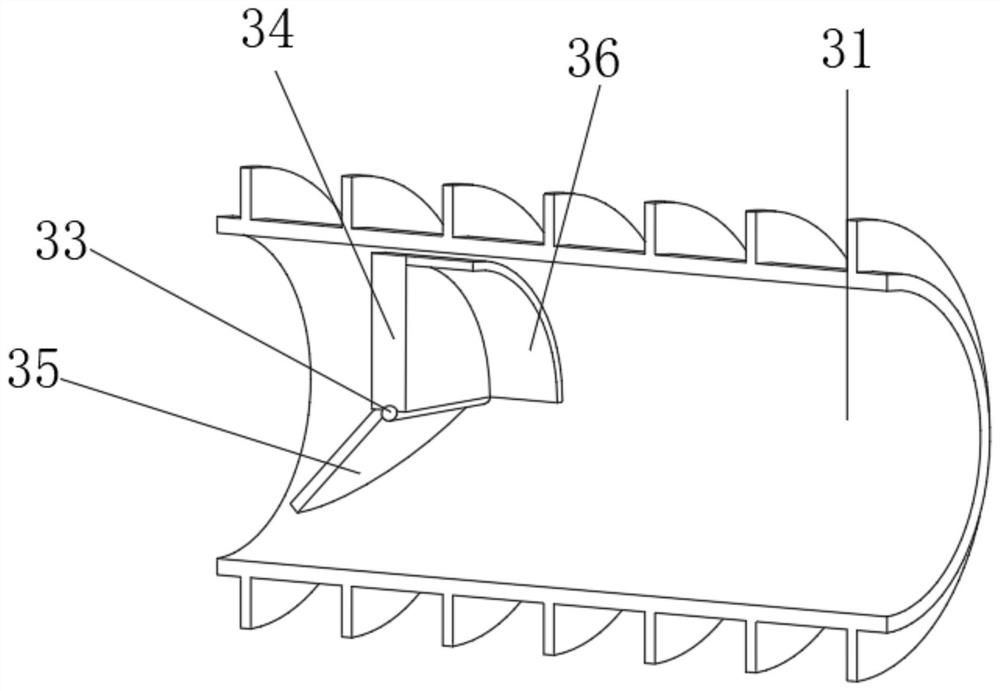

[0038] The corrugated conductive mechanism 3 includes a corrugated telescoping rod 31, and both ends of the corrugated telescoping rod 31 communicate with the liquid pipe 1 and the liquid pipe 2, and the surface of the corrugat...

Embodiment 2

[0042] Such as Figure 4-5 As shown, in the first embodiment, the present invention provides a technical solution: a high pressure water supply pipe, the active dredge mechanism 7 includes a dredging of the inner tube 71, and is fixed to the inner tube 71 and close to the corrugation conduction mechanism 3. There is auxiliary filter assembly 72, and the side of the interior of the inner tube 71 is fixedly coupled with the moving chute 73, and the inner sliding connection of the moving chute 73 has a support slider 74.

[0043] The support slider 74 is fixedly connected to one end of the moving chute 73, and the negative pressure baffle 75 is uniformly secured to the surface of the support slider 74 and the auxiliary culling assembly 76. Active filtration collected by impurities in the pipeline is realized to facilitate workers to look for clogging.

Embodiment 3

[0045] Such as Figure 6 As shown, in the basis of the first and embodiment 2, the present invention provides a technical solution: a high pressure water supply pipe, the auxiliary filter assembly 72 includes auxiliary lever 721, the right side of the auxiliary gear rod 721 fixed connection with a shovel. The tapered rod 722, the shovel cone 722 corresponds to the negative pressure baffle 75.

[0046] The vertical position inside the auxiliary lever 721 is uniformly provided with filtering groove 723, and the upper and lower ends of the inside of the filter retaining groove 723 are fixedly coupled to the reverse cutting hook 724. Under the pressing, impurities are cut, reduce impurity particle size, and realize the initiative to impurities, avoid impurities to block downstream.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com