A composite plugging agent with high temperature resistance and salt resistance

A technology of blocking agent and stabilizer, which is applied in the field of composite blocking agent with high temperature resistance and salt resistance, can solve the problems of increased degree of hydrolysis, excessive cross-linking, blocking by forming glue and not forming glue, etc., so as to improve the swelling resistance and temperature resistance performance. The effect of improving toughness and compactness, reducing formulation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

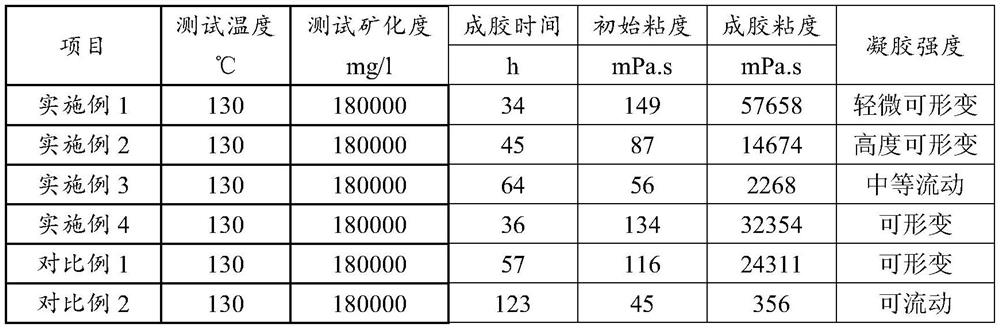

Embodiment 1

[0033] A composite plugging agent with high temperature resistance and salt resistance, its components and mass percentages are:

[0034] Phenolic prepolymer 25%, sodium organosilicate 25%, β-cyclodextrin polymer 10%, cross-linking agent 5%, active siloxane 10%, sodium polyphosphate 2.5%, stabilizer 5%, appropriate amount Deionized water.

[0035]Add the sodium organosilicate, phenolic prepolymer, active siloxane, β-cyclodextrin polymer, and sodium polyphosphate into the stirring reactor in turn, stir for 2 hours, and mix evenly to form an amphiphilic inclusion system, and add a stabilizer and cross-linking agent to form a gel conditioner.

[0036] The preparation method of the phenolic prepolymer is that under the action of an alkaline catalyst, the phenol and formaldehyde having a molar ratio of 2.5: 1 to 3: 1 are sucked into the reactor in batches with a vacuum pump, and the temperature is 50 ℃ to 60 ℃. It is prepared by reacting for about 4-5 hours, and the methylol cont...

Embodiment 2

[0045] The difference with Example 1 is: the mass percentage of the components is:

[0046] Phenolic prepolymer 15%, sodium organosilicate 15%, β-cyclodextrin polymer 10%, crosslinking agent 2.5%, reactive siloxane 10%, sodium polyphosphate 2.5%, stabilizer 5%, appropriate amount Deionized water. The test results are shown in Table 1.

Embodiment 3

[0048] The difference with Example 1 is: the mass percentage of the components is:

[0049] Phenolic prepolymer 15%, sodium organosilicate 15%, β-cyclodextrin polymer 10%, crosslinking agent 2.5%, active siloxane 10%, sodium polyphosphate 2.5%, stabilizer 2.5%, appropriate amount Deionized water. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com