Method for one-step synthesis of ZSM-5 molecular sieve in solid phase system

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high energy consumption, complicated operation steps, large pollution, etc., and achieve product crystallization The effect of high efficiency, elimination of high-voltage safety hazards, and improvement of utilization rate and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.2g tetrapropylammonium bromide (TPABr), 0.336g ammonium bifluoride (NH 4 HF 2 ), 1g sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O), 0.0744g aluminum isopropoxide, poured in the mortar, after grinding and mixing for 15 minutes, the pasty or pasty mixture after mixing was moved in the steel reaction kettle of polytetrafluoroethylene lining, at 160 ℃ After crystallization for 24 hours, the reaction product was washed with ethanol and deionized water, and the filter cake was transferred to a blast drying oven at a drying temperature of 60°C for 12 hours or more to obtain the final product. In this system, the molar ratio of raw materials is: n(TPABr):n(NH 4+ ): n(SiO 2 ): n (water of crystallization) = 0.20: 1.60: 1.0: 8.60; Si / Al = 10.

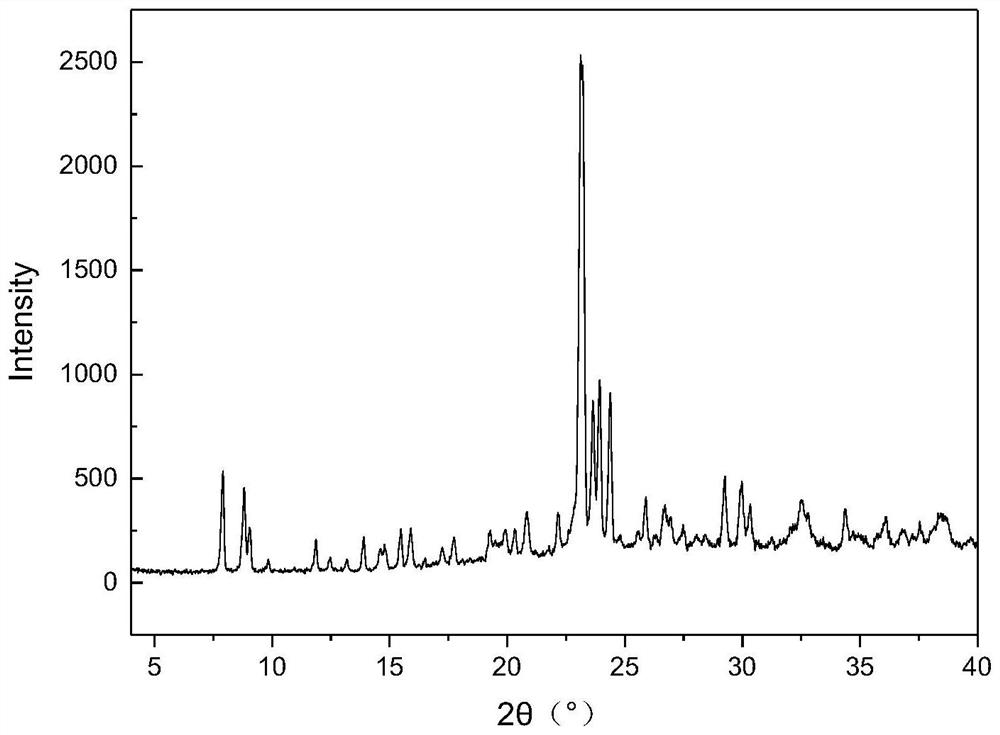

[0026] attached figure 1 It is the XRD characterization result of Example 1. From the characteristic diffraction peaks, it can be known that the product is a pure phase of MFI and has a high degree of crystallinity.

Embodiment 2

[0028] Weigh 0.2g tetrapropylammonium bromide (TPABr), 0.336g ammonium bifluoride (NH 4 HF 2 ), 1g sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O), 0.0744g aluminum isopropoxide, 0.226g fumed silica, pour into a mortar, grind and mix for 15 minutes, transfer the mixed paste or paste mixture to a Teflon-lined steel In a reaction kettle, crystallize at 160°C for 24 hours, wash the reaction product with ethanol and deionized water, and transfer the filter cake to a blast drying oven at a drying temperature of 60°C for 12 hours or more to obtain the final product. In this system, the molar ratio of raw materials is: n(TPABr):n(NH 4+ ): n(SiO 2 ): n (water of crystallization) = 0.10: 0.80: 1.0: 4.30; Si / Al = 20.

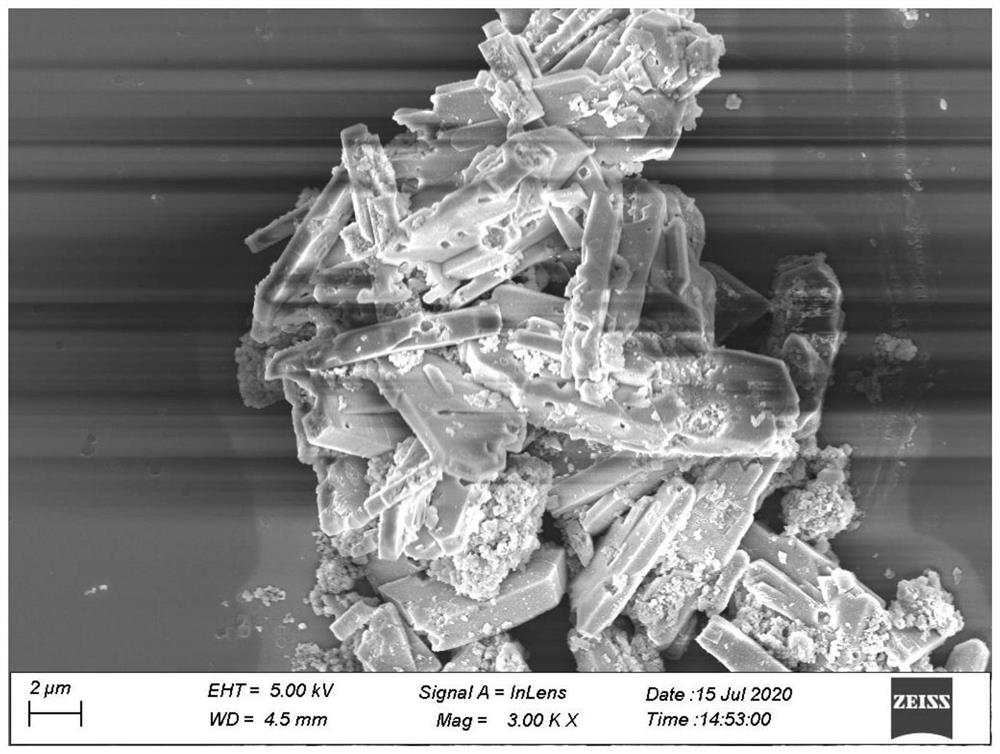

[0029] attached figure 2 It is the XRD characterization result of Example 2. From the characteristic diffraction peaks, it can be known that the product is MFI pure phase, and the crystallinity is relatively high. attached image 3 It is a scanning electron ...

Embodiment 3

[0031] Weigh 0.2g tetrapropylammonium bromide (TPABr), 0.336g ammonium bifluoride (NH 4 HF 2 ), 1g sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 (2), 0.037g aluminum isopropoxide, 0.226g silicon micropowder, pour in the mortar, after grinding and mixing for 15 minutes, move the mixed paste or pasty mixture to the steel reactor of polytetrafluoroethylene lining crystallization at 160°C for 24 hours, the reaction product was washed with ethanol and deionized water, and the filter cake was transferred to a blast drying oven at a drying temperature of 60°C for 12 hours or more to obtain the final product. In this system, the molar ratio of raw materials is: n(TPABr):n(NH 4+ ): n(SiO 2 ): n (water of crystallization) = 0.10: 0.80: 1.0: 4.30; Si / Al = 40.

[0032] attached Figure 4 It is the XRD characterization result of Example 3. From the characteristic diffraction peaks, it can be seen that the product is MFI pure phase, and the crystallinity is relatively high. attac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com