A method of preparing a selenium nanomaterial

A germanium diselenide and nanomaterial technology, applied in the field of germanium diselenide preparation, can solve the problems of high cost, complex preparation process, inability to realize industrial application, etc., and achieve the effects of effective growth regulation, fast and efficient growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

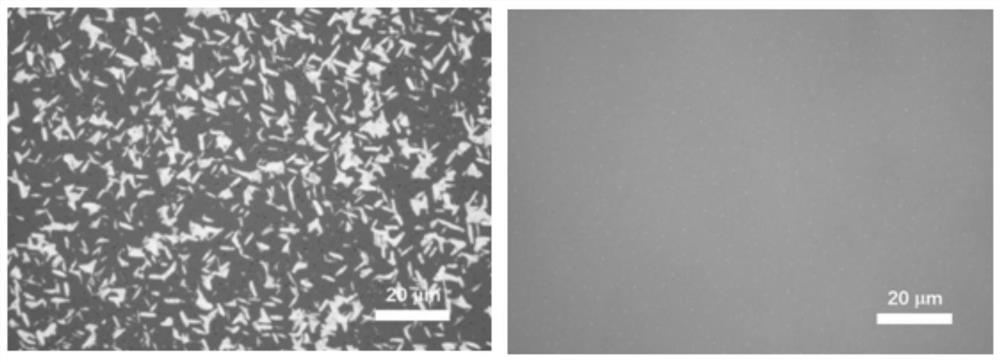

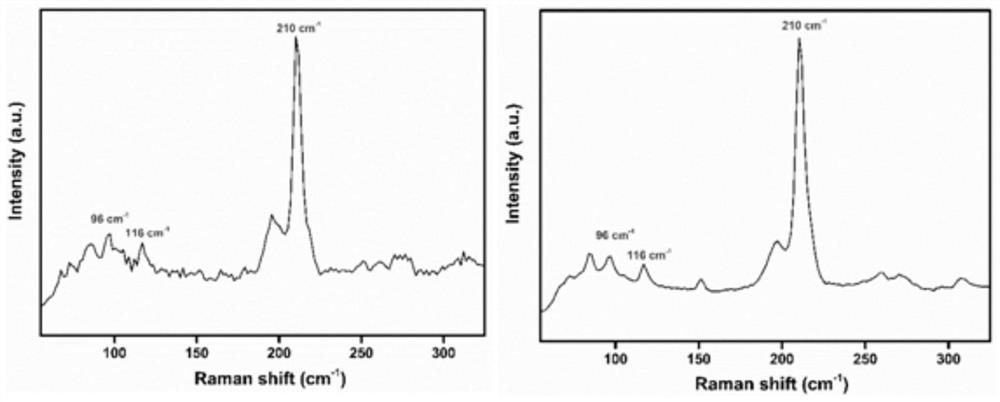

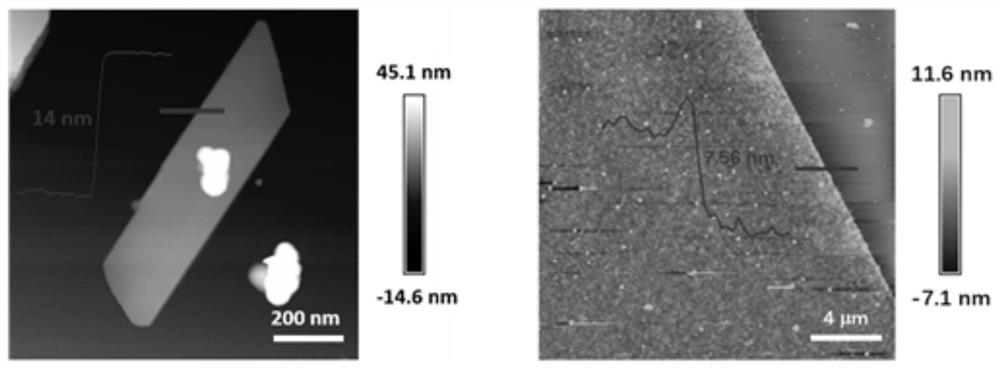

Embodiment 1

[0031] The fluorocrystalline mica substrate was treated with tape and the fresh surface was torn off. According to the order of air flow from upstream to downstream, put germanium selenide powder (placed outside the heating area), fluorine crystal mica sheet (downstream from the heating center 11-13cm), and the mica sheet is 6mm from the bottom of the quartz tube. , the mass of germanium selenide powder is 30mg. Then, argon gas (500 sccm) was introduced into the reaction chamber, the reaction chamber was cleaned, and the residual air in the chamber was discharged, and the cleaning time was 30 minutes. Subsequently, the temperature was programmed so that the heating core temperature of the tube furnace reached 570°C. Argon gas (5 sccm) was used as a carrier gas to transport the reactive species of germanium diselenide to the mica substrate to realize the growth of germanium diselenide nanomaterials, and the growth time was 12 minutes. After the growth, the temperature of the ...

Embodiment 2~7

[0034] The fluorocrystalline mica substrate in Example 1 was replaced by graphene, high pyrolytic graphite, and two-dimensional layered materials such as tungsten disulfide, molybdenum diselenide, and tungsten diselenide, respectively. The experimental results show that these two-dimensional layered materials can also obtain germanium diselenide nanobelts and nanofilms with good quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com