Directional growth GeSe2 nanowire and preparation method thereof

A technology for directional growth and nanowires, applied in the field of directional growth of GeSe2 nanowires and their preparation, can solve the problems of long time required for preparation methods, difficult to control reaction conditions, expensive precursor materials, etc., to achieve controllable growth, The effect of easy control of reaction conditions and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

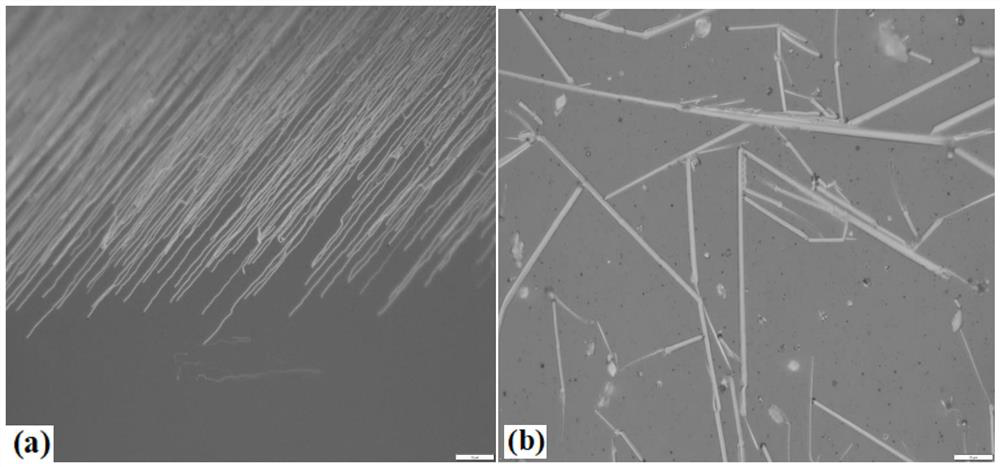

[0030] The invention discloses a directional growth GeSe 2 A method for preparing nanowires, specifically comprising the following steps:

[0031] (1) Preparation of materials and utensils

[0032] Prepare two oval ceramic stone boats with a length of 6-8cm, a width of 0.8-1.2cm, and a groove with a depth of 0.4-0.6cm inside. The wall thickness of the stone boat is 0.1-0.2cm;

[0033] Prepare a mica sheet with a length of 2-4 cm, a width of 1.5-3.5 cm, and a thickness of 0.05-0.15 mm.

[0034] Place a certain quality of selenium powder in the middle of one of the stone boats and spread it evenly; place a certain quality of germanium powder in the middle of the other stone boat and spread it evenly, then place the germanium powder in the center of the stone boat for preparation For a good mica substrate, the mica substrate is just suspended above the germanium powder, and at this time, air flow can pass under the mica substrate. Wherein, the mass of the selenium powder and t...

Embodiment 1

[0045] Place 0.23g (0.0029mol×99%) of selenium powder and 0.12g (0.0017mol×99%) of germanium powder in the middle of the two stone boats, spread them evenly, and place them in the center of the germanium powder. The mica substrate, so that the mica substrate just hangs above the germanium powder. Place two stone boats containing selenium powder and germanium powder in the left and right heating chambers of the vacuum atmosphere furnace respectively, and seal the atmosphere furnace. Pass argon gas from the side of the selenium powder to carry out the scrubbing operation, and the flow rate of the argon gas and the scrubbing time are shown in Table 1 below. After the washing is completed, the growth conditions are set, as shown in Table 2 below for details. Then start the heating button, and when the temperature of the two heating chambers exceeds 100°C, adjust the argon flow rate, and simultaneously add hydrogen gas from the side of the selenium powder. The argon gas flow rate ...

Embodiment 2

[0056] Place 0.36g (0.0046mol×99%) of selenium powder and 0.16g (0.0022mol×99%) of germanium powder in the middle of the two stone boats, spread them evenly, and place them in the center of the germanium powder. The mica substrate, so that the mica substrate just hangs above the germanium powder. Place two stone boats containing selenium powder and germanium powder in the left and right heating chambers of the vacuum atmosphere furnace respectively, and seal the atmosphere furnace. Pass argon gas from the side of the selenium powder to carry out the scrubbing operation, and the flow rate of the argon gas and the scrubbing time are shown in Table 3 below. After the gas washing is completed, the growth conditions are set, as shown in Table 4 below for details. Then start the heating button, and when the temperature of the two heating chambers exceeds 100°C, adjust the flow of argon, and add hydrogen from the side of the selenium powder at the same time, the flow of argon and hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com