Package, method for storing or transporting polyvinyl alcohol film, polyvinyl alcohol film, and polarizing film

A technology of polyvinyl alcohol series and packaging body, which is applied in the direction of packaging, transportation and packaging, special packaging objects, etc., can solve the problems of uneven polarization degree of polarizing film, film deformation, uneven color, etc. Offset, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

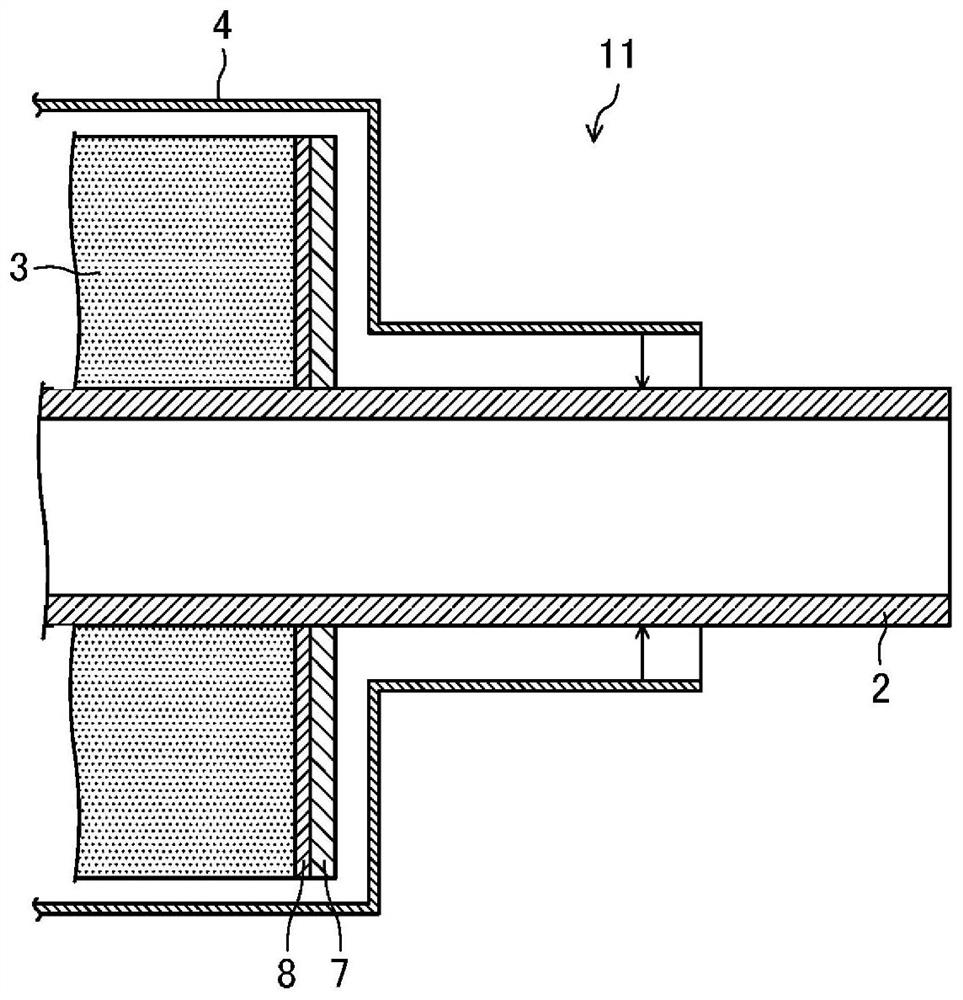

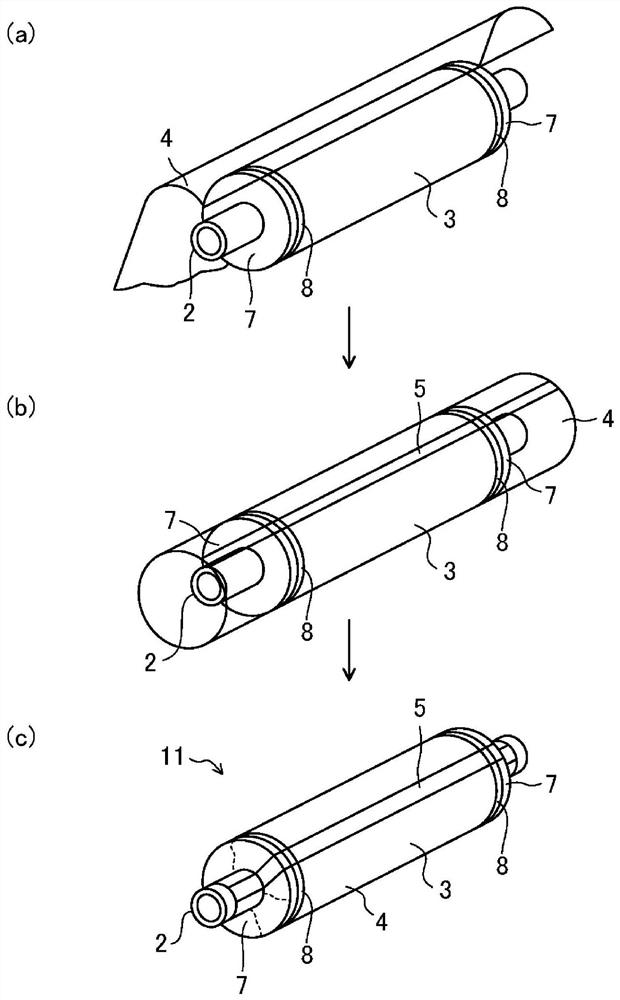

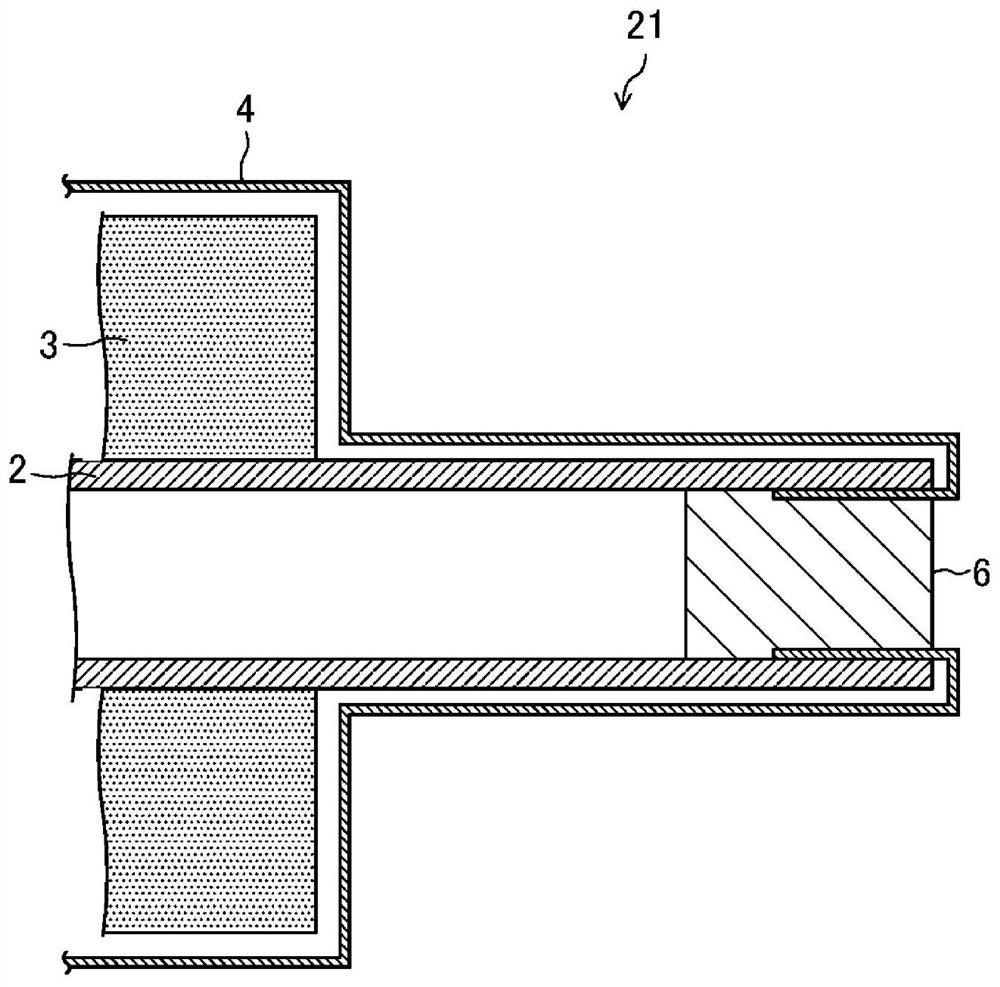

[0175] (manufacturing of film rolls)

[0176] Add 1000kg of polyvinyl alcohol-based resin with a weight average molecular weight of 142000 and a saponification degree of 99.8 mol%, 2500kg of water, and 100kg of glycerin as a plasticizer, and heat up to 140°C while stirring, and adjust the concentration to a resin concentration of 25% by weight to obtain a uniform Dissolved polyvinyl alcohol-based resin aqueous solution.

[0177] Next, after supplying the aqueous solution of polyvinyl alcohol-based resin to a twin-screw extruder for defoaming, the temperature of the aqueous solution was set at 95°C, and it was sprayed and cast on a pouring drum with a surface temperature of 90°C from a T-shaped slot die outlet. to film.

[0178] Next, the obtained film was dried with a plurality of metal heating rolls, heat-treated using a suspension dryer, and cut to a width of 4 m by a cutter. Finally, it was wound up on an aluminum core pipe with an outer diameter of 17 cm, an inner diamet...

Embodiment 2

[0188] As the water vapor barrier film, a laminate with a hygroscopic film (NS-APP manufactured by Nissin Seal Industry Co, Ltd.) was used, and the humidity-conditioning sheet was not used, and the packaging was carried out in the same manner as in Example 1. production, storage, and production of polarizing films. The results are shown in Table 1 and Table 2.

Embodiment 3

[0190] As a water vapor barrier film, a laminated film of aluminum-deposited polyester film (polyethylene terephthalate film, 12 μm thick) and polyethylene film (25 μm thick) was prepared, and the packaging A humidity indicator (manufactured by Fujita Electric Manufacturing Co., Ltd., "WATCHLOGGER KT-275") was pasted on the polyethylene side of the inner surface.

[0191] Next, in an environment of 23° C. and 50% RH, two layers of the above-mentioned water vapor barrier film were wound on the film roll of Example 1 with the polyethylene film inside. The axial end of the core tube in the water vapor barrier film was fixed to the outer periphery of the end of the core tube protrusion (0.2 m at both ends) with a rubber band, and the remaining part of the water vapor barrier film was wrapped around the core tube. The way the ends fold into the inside of the core tube. It should be noted that the length of the water vapor barrier film portion folded in from one end of the core tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com