An environment-friendly vertical machining CNC machine tool

A CNC machine tool and vertical technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as low consumer experience, unreasonable structure, and development trends that do not meet environmental protection requirements, and achieve Avoid air leakage of the machine tool and improve the experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

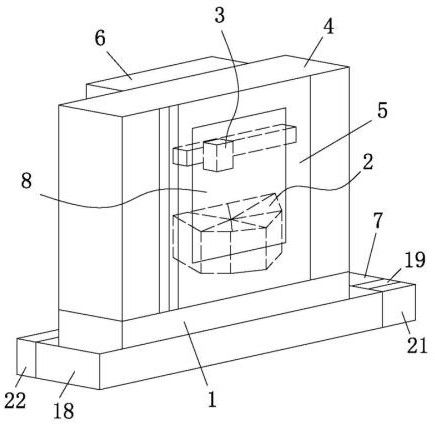

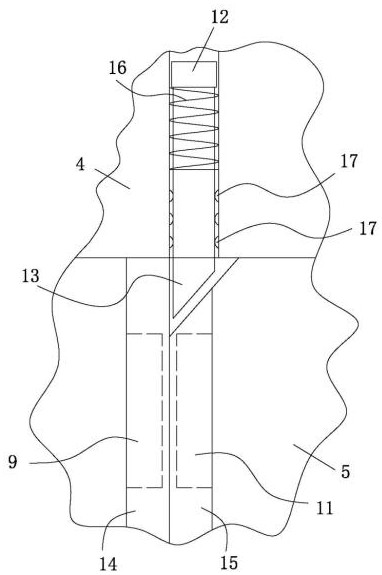

[0030] see Figure 1 to Figure 4 As shown, an environment-friendly vertical machining CNC machine tool of the present invention includes a base 1, a bearing mechanism 2 fixedly installed on the base 1 and a support frame, which is movably arranged on the support frame and located above the bearing mechanism 2 The CNC machining head 3, the carrying mechanism 2 is used to carry the object to be processed, and the CNC processing head 3 is used to process the object carried by the carrying mechanism 2.

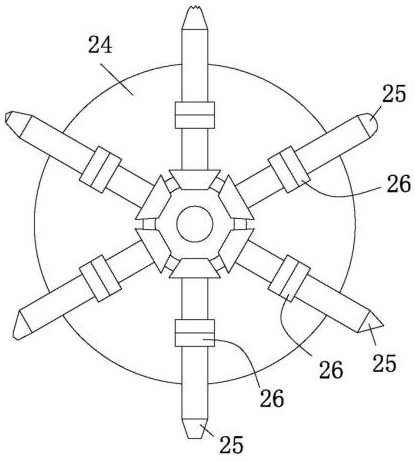

[0031] In this embodiment, the carrying mechanism 2 includes a cam splitter, a carrier plate installed on the output shaft of the cam splitter, a first motor for driving the input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com