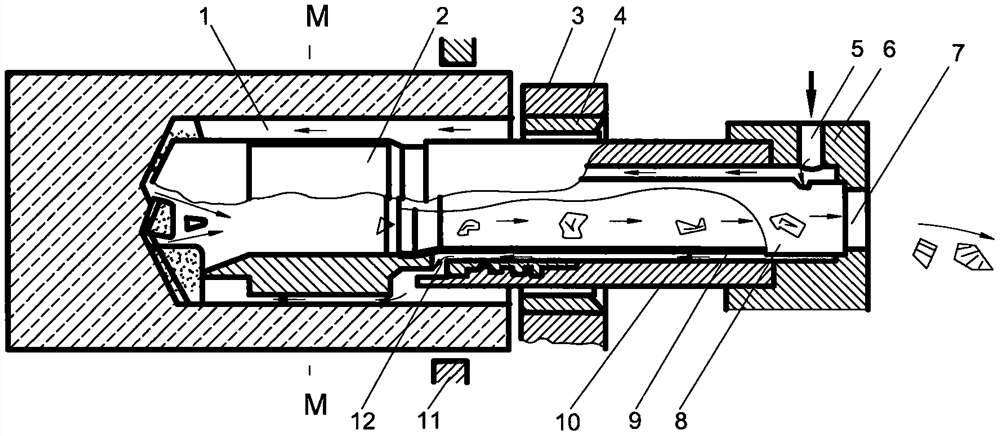

Hole machining ejector drill system and drill bit thereof

A technology of spray suction drilling and hole processing, which is applied in the field of hole processing and can solve problems such as difficulty in chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention are further described below, and the specific embodiments do not limit the present invention in any way.

[0046] 1. The wedge-shaped protrusion is a connecting structure or an integral structure.

[0047] 2. The force of the liquid is adjusted by mechanical, electrical or magnetic means.

[0048] 3. The wedge-shaped profile of the wedge-shaped convex part is a circle, or an Archimedean spiral surface, a straight line, other curves, or a combination of the above lines.

[0049] 4. The blades are arranged symmetrically or asymmetrically; the cutting fluid is oil or other liquid, which is filtered through a filter, centrifugal force, or magnetically.

[0050] 5. The wedge-shaped protrusion or the adjusting pad is in contact with the positioning piece.

[0051] 6. The material and heat treatment requirements of the top of the wedge-shaped protrusion are the same as or different from the material and heat treatment requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com