A steel pipe anti-rust coating device for steel processing

An anti-rust coating and brushing technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of unsatisfactory brushing speed and cumbersome operation, and achieve fast brushing speed and prevent paint waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

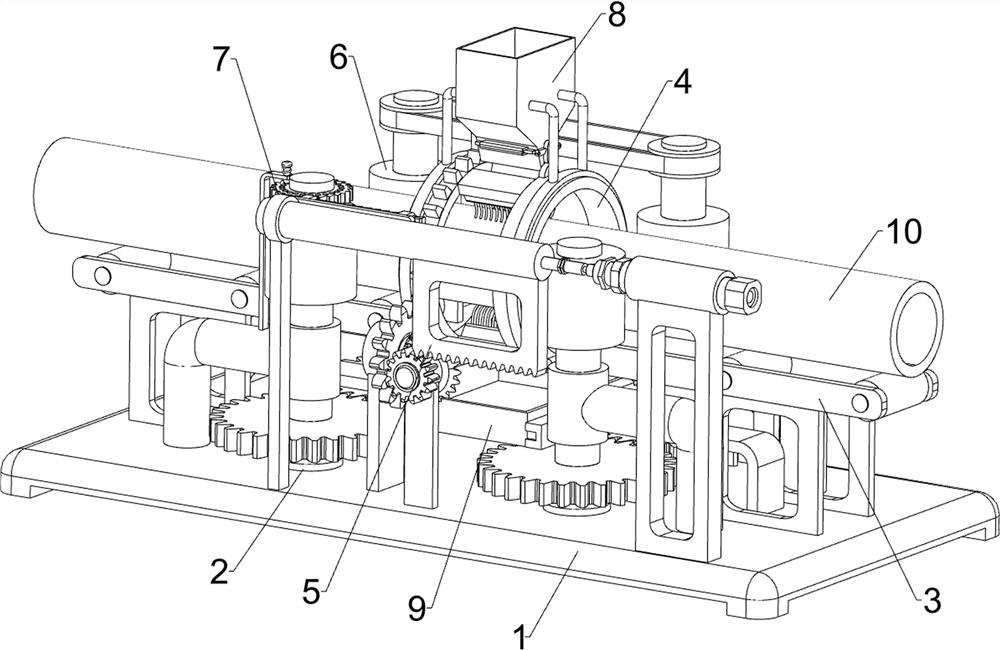

[0030] A steel pipe antirust coating brushing device for steel processing, such as Figure 1-2 As shown, it includes a base 1, a support 2, a conveying assembly 3, a brushing mechanism 4, and a driving mechanism 5. Two supports 2 are symmetrically connected to the front and rear sides of the top of the base 1, and the conveying assembly is installed on the base 1. 3. A brushing mechanism 4 is installed on the conveying component 3 , a driving mechanism 5 is installed on the base 1 , and the driving mechanism 5 is connected with the brushing mechanism 4 through transmission.

[0031] The conveying assembly 3 includes a fixed support frame 31, a first fixed frame 32 and a rotating roller 33. Two fixed support frames 31 are symmetrically connected to the left and right sides of the top of the base 1, and the top of the fixed support frame 31 is connected to a first fixed frame 32. A plurality of rotating rollers 33 are rotatably connected between the first fixed frames 32 on the ...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 3-5 As shown, a moving mechanism 6 is also included, and the moving mechanism 6 includes a second ring frame 61, a runner frame 62, an opposing gear set 63 and a transmission belt set 64, and the front and rear sides of the top of the base 1 are symmetrically connected. There are two second ring frames 61, and a runner frame 62 is rotatably connected between the second ring frame 61 and the support 2, and an opposing gear set 63 is connected between the bottom ends of the wheel frames 62 on the front and rear sides. , a drive belt set 64 is connected between the two runner frames 62 tops on the rear side.

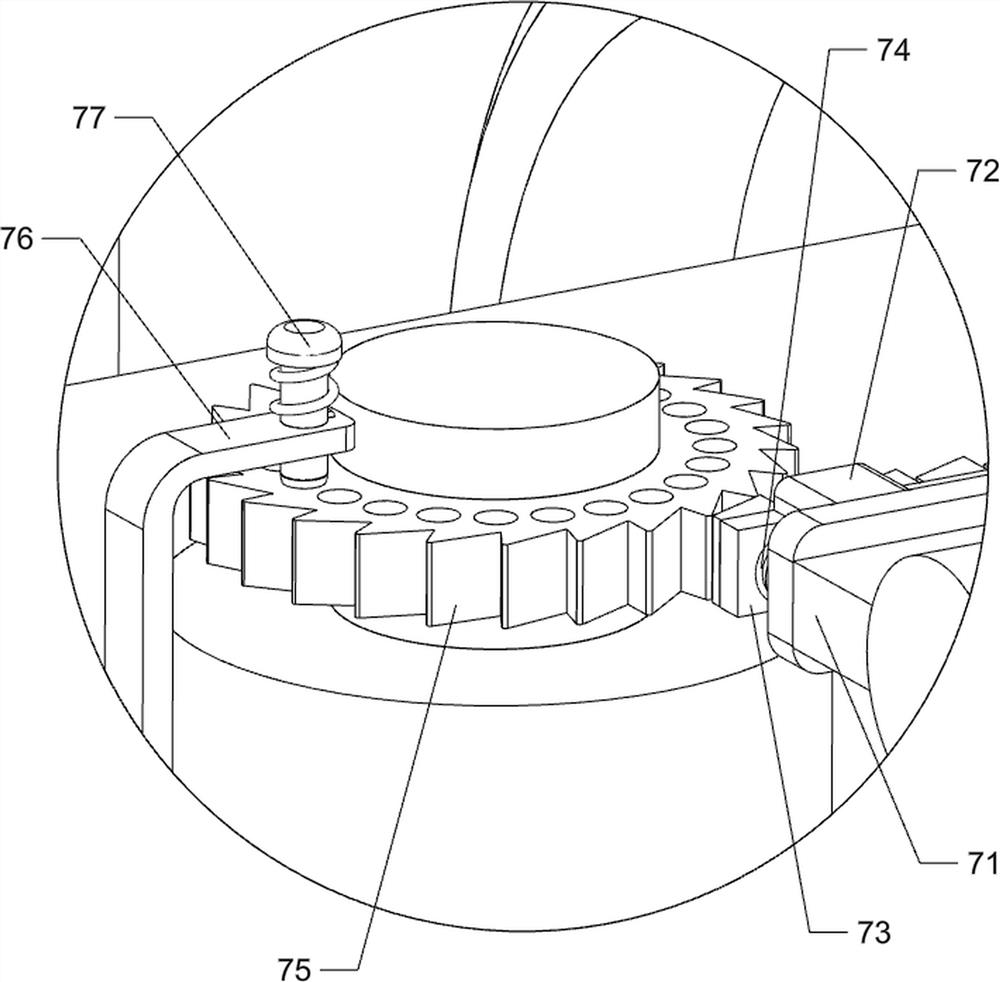

[0037] Also includes a linkage mechanism 7, the linkage mechanism 7 includes a second fixed mount 71, a guide rail plate 72, a sliding flat gear rod 73, a first return spring 74, a slotted ratchet gear 75, a third fixed mount 76 and a first elastic pin 77, the left side of the rear side of the push rod 52 is connected with ...

Embodiment 3

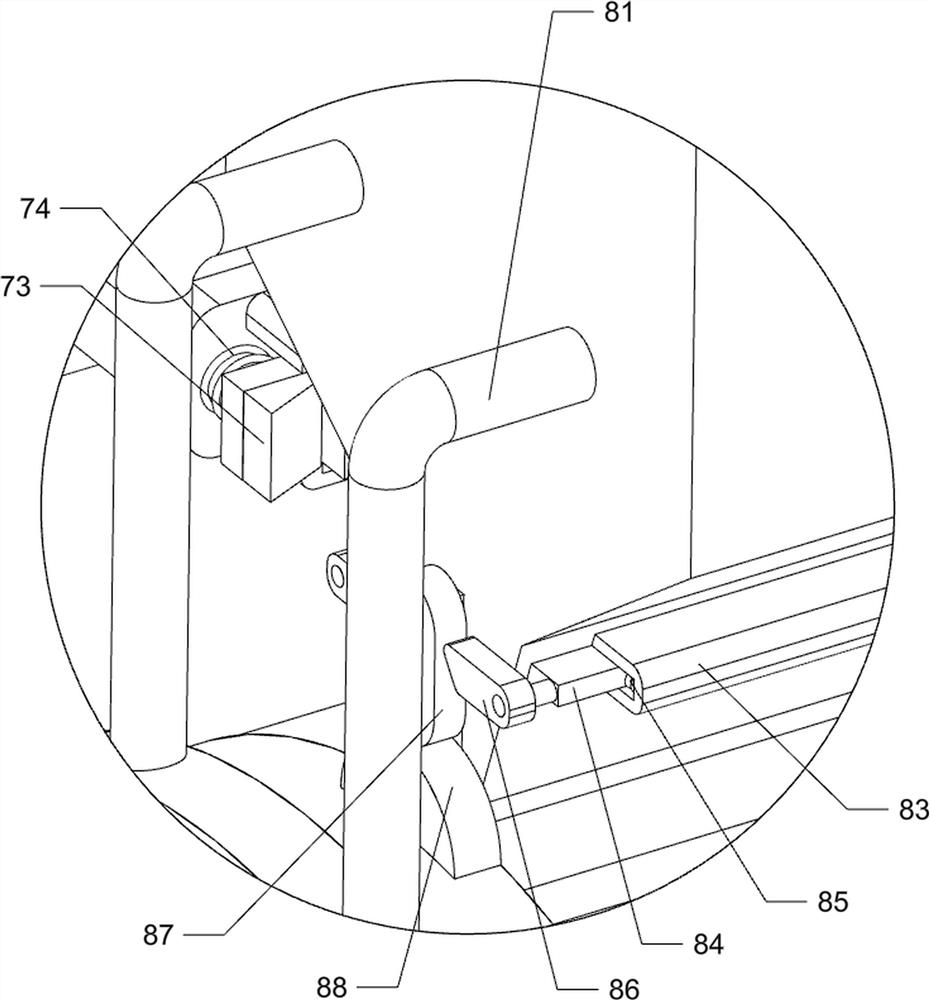

[0040] On the basis of Example 2, such as figure 1 , image 3 and Figure 5 As shown, it also includes a blanking mechanism 8, and the blanking mechanism 8 includes a fourth fixed frame 81, a storage tank 82, a guide frame 83, a sliding plate 84, a second return spring 85, a wedge block 86, and a sliding top block. 87 and a fixed top block 88, two fourth fixed mounts 81 are connected to the top of the first ring frame 41, and storage barrels 82 are connected between the tops of the four fourth fixed mounts 81, and the front and rear sides of the bottom of the storage barrel 82 Both are connected with a guide frame 83, the guide frame 83 is slidably connected with a sliding board 84, the sliding board 84 is slidably connected with the storage barrel 82, and there are two left and right symmetrical connections between the sliding board 84 and the guide frame 83. The second return spring 85, the right side of the sliding plate 84 is connected with a wedge block 86, the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com