Continuous roller type kaolin mashing system

A kaolin and drum-type technology, which is applied in the direction of chemical instruments and methods, chemical/physical processes, wet separation, etc., can solve the problems of ineffective control of the production process, large influence of human factors, and unfavorable selection process for deep processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

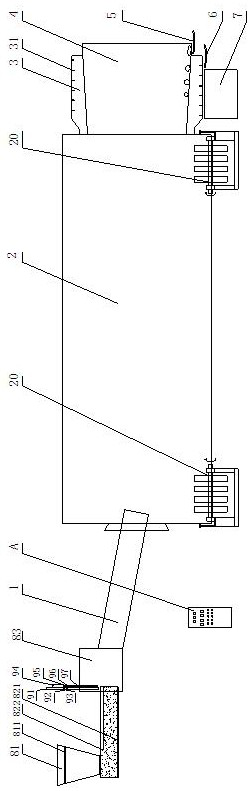

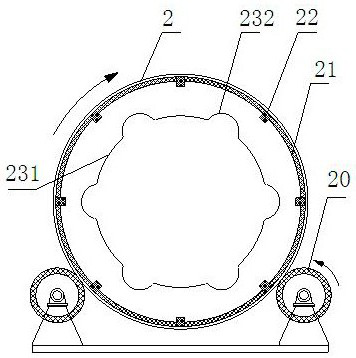

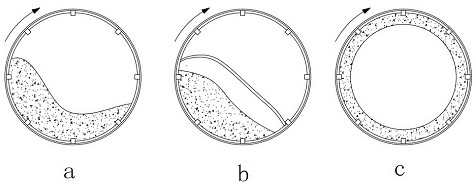

[0026] Such as figure 1 , figure 2 , the continuous drum type kaolin pounding system of the present invention comprises a continuous feeding mechanism, an inclined feed pipe 1 and a horizontally placed beating drum 2, the entrance of the beating drum 2 is connected to the bottom of the inclined feed pipe 1, The inner wall of the pulping drum 2 is a wear-resistant lining plate 21, and the inner wall of the pulping drum 2 is provided with 8 rubber slats 22 along the axial direction. The through hole includes an inner circle through hole 231, and the edge annular array of the inner circle through hole 231 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com