Rock cross-cut coal uncovering high-pressure hydraulic flushing comprehensive permeability enhancement method

A technology of hydraulic punching and coal removal in Shimen, which is applied in the direction of earthwork drilling, gas discharge, mining fluid, etc., can solve the problem of unsatisfactory anti-permeability effect of coal seam, and achieve the purpose of increasing the flow rate of punching water, punching pressure and increasing Penetration range, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

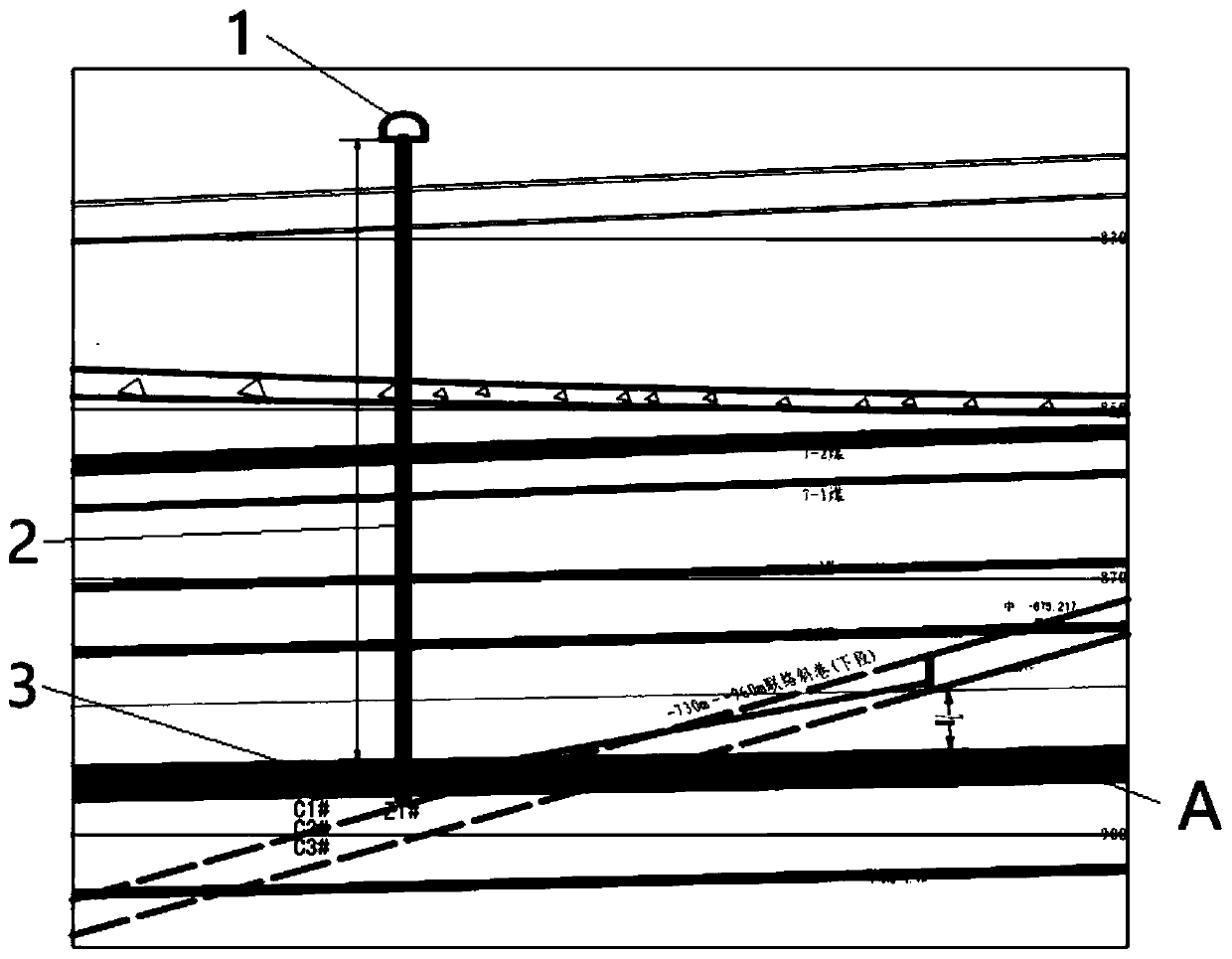

[0037] The comprehensive anti-permeability method of high-pressure hydraulic punching for Shimen unraveling coal is illustrated by using hydraulic punching comprehensive anti-permeability at the -730~-960m contact inclined roadway to uncover the 5-2 coal working face. The 5-2 coal seam A is the coal seam to be uncovered, including The following steps:

[0038] Step S1: Construct an auxiliary roadway 1 above the 5-2 coal seam A, the roof elevation of the roadway is -814m, and the vertical distance from the 5-2 coal seam is 74m; in the auxiliary roadway 1, construct a ¢246mm vertical drilling 2 (hole number is Z1# ), the end point of the vertical borehole 2 is located at a position below 1 meter below the bottom plate of the 5-2 coal seam A; the technological parameters are as follows in Table 1:

[0039]

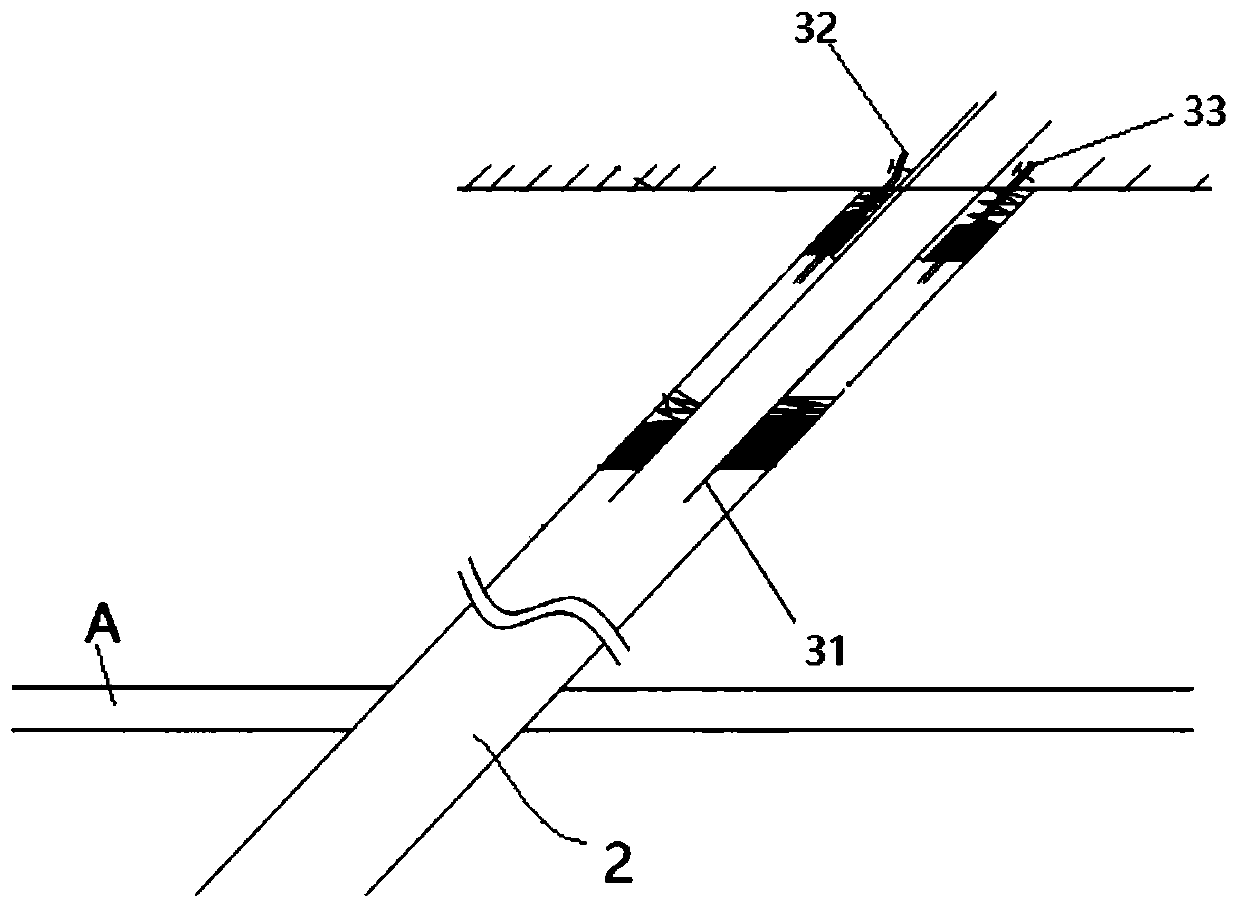

[0040] Step S2: Use the ¢177.8mm oil casing pipe fixing process to seal the vertical borehole and fix the pipe;

[0041] In this embodiment, large-diameter vertical punch...

Embodiment 2

[0052] In this embodiment, on the basis of Embodiment 1, the specific operation process of step S4 is:

[0053] The first stage, hydrostatic flushing

[0054] From the 1st day to the 16th day, first use static pressure water to punch holes, the punching pressure is kept at 3.5-4Mpa, and each small class punches for 3-4 hours. During the punching process, arrange a special person to observe the head. Punching makes Z1# hole directly connected with C1# hole, water and coal flow are sprayed from C1# hole, and the total water injection volume is 250m 3 , 20 tons of coal were washed out.

[0055] The second stage, high pressure water pressure

[0056] From the 17th shift to the 31st day, the C1# hole is closed, and the water injection pump is used for high-pressure water injection and pressure flushing, and the pressure is controlled below 20Mpa. After fracturing, the Z1# hole is connected with the C2# and C3# holes, and the water and coal flow from C2 #, C3# holes spray out, th...

Embodiment 3

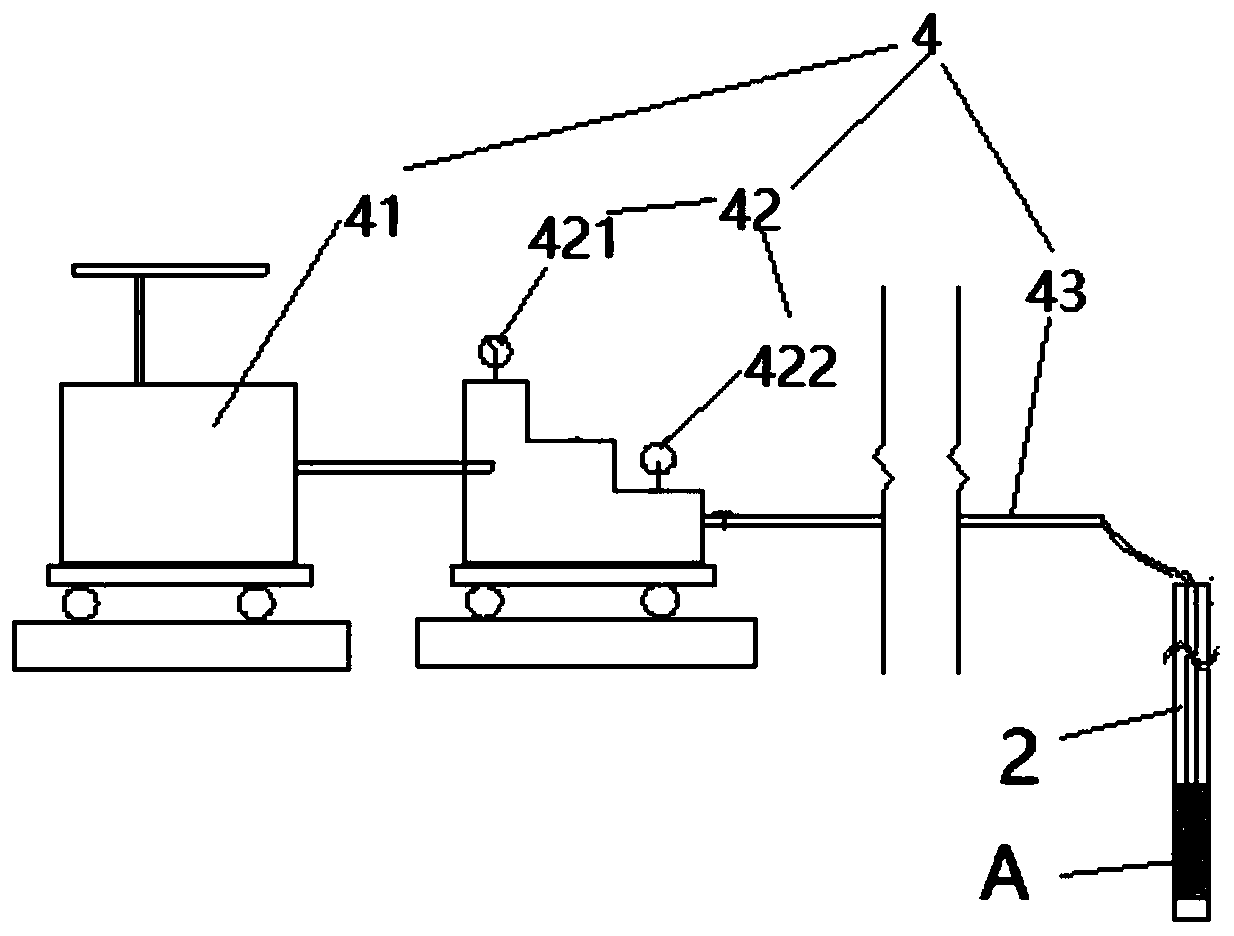

[0065] like Figure 4 As shown, on the basis of Embodiment 2, 180 outburst prevention measures holes have been constructed on the working face; it can be constructed according to actual needs;

[0066] The inspection of gas drainage volume is as follows in Table 4:

[0067]

[0068]

[0069] After the 34th day (press stamping has been completed), the average scalar volume of single hole drainage has reached 0.0148m 3 / min, 100-hole extraction scalar volume 1.48m 3 / min.

[0070] Taking the B coal seam that has been uncovered as an example, the measured gas pressure of B coal in this working face was 1.5MPa, and the gas content was 6.7m3 / t. The volume is 0.0047m3 / min, and the scalar volume of 100-hole drainage is 0.47m3 / min.

[0071] Through comparative analysis, after adopting high-pressure hydraulic punching and anti-permeability measures, the scalar volume of 100-hole drainage in the coal mining face in Shimen increased from 0.47m3 / min to 1.48m3 / min, an increase of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com