Catalyst for pollutant degradation under natural light and preparation method of catalyst

A natural light and catalyst technology, applied in physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve the problems of human and environmental damage, cumbersome preparation process, secondary pollution of by-products, etc., and reduce production costs. , Large specific surface area, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 1g of Spartina alterniflora to 200ml of ethanol, incubate at 70°C for 2 hours, and filter to prepare Spartina alterniflora filtrate;

[0044] Take 10ml of Spartina alterniflora filtrate, add 5.6g of zinc acetate, 1.8g of sodium hydroxide, 0.2g of Spartina alterniflora powder, stir, and sonicate for 2 hours to obtain 20ml of loaded biochar-ZnO nanoparticle precursor;

[0045] React the biochar-ZnO nanoparticle precursor prepared above in a 70°C water bath for 5 hours to prepare 18ml of biochar-ZnO nanoparticle precursor carbon airgel;

[0046] The above-mentioned loaded biochar-ZnO nanoparticle precursor carbon airgel was centrifuged at 8000r / min for 2min, and dried at 60°C to obtain 3.2g of the dried loaded biochar-ZnO nanoparticle precursor carbon airgel;

[0047] The dried loaded biochar-ZnO nanoparticle precursor carbon aerogel was calcined at 900 °C in anaerobic high temperature to obtain 2.4 g of biochar-ZnO nanoparticle composite catalyst.

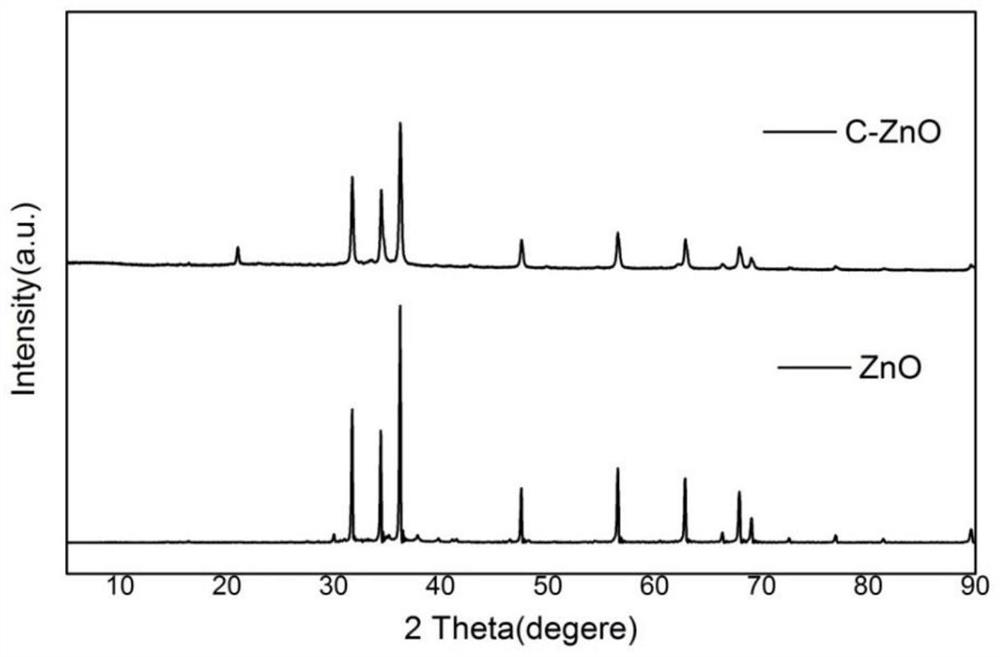

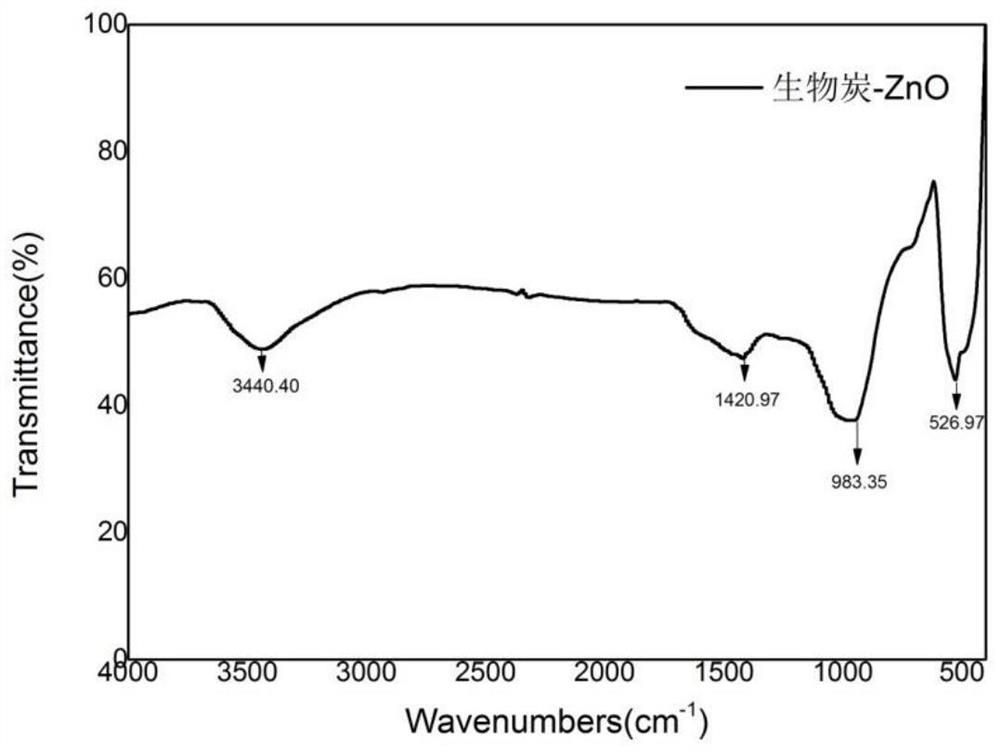

[0048] X-ray diff...

Embodiment 2

[0056] Add 1g of Spartina alterniflora to 200ml of ethanol, incubate at 70°C for 2 hours, and filter to prepare Spartina alterniflora filtrate;

[0057] Take 10ml of Spartina alterniflora filtrate, add 5.6g of zinc acetate, 1.8g of sodium hydroxide, 2.8g of Spartina alterniflora powder, stir, and sonicate for 2 hours to obtain 21.3ml of biochar-ZnO nanoparticle precursor;

[0058] React the loaded biochar-ZnO nanoparticle precursor prepared above in a 70°C water bath for 5 hours to prepare 19.1ml of loaded biochar-ZnO nanoparticle precursor carbon airgel liquid;

[0059] Prepare the above-mentioned loaded biochar-ZnO nanoparticle precursor carbon airgel, centrifuge at 8000r / min for 2min, and dry at 60°C to obtain 3.61g of loaded biochar-ZnO nanoparticle precursor carbon airgel after drying;

[0060] The dried loaded biochar-ZnO nanoparticles precursor carbon aerogel was calcined at 900 °C in anaerobic high temperature to obtain 3.13 g of biochar-ZnO nanoparticles composite cat...

Embodiment 3

[0063] Add 1g of Spartina alterniflora to 200ml of ethanol, incubate at 70°C for 2 hours, and filter to prepare Spartina alterniflora filtrate;

[0064] Take 10ml of Spartina alterniflora filtrate, add 5.6g of zinc acetate, 1.8g of sodium hydroxide, 2g of Spartina alterniflora powder, stir, and sonicate for 2 hours to obtain 20.8ml of biochar-ZnO nanoparticle precursor;

[0065] React the loaded biochar-ZnO nanoparticle precursor prepared above in a 70°C water bath for 5 hours to prepare 18.5ml of loaded biochar-ZnO nanoparticle precursor carbon airgel;

[0066] The above-mentioned loaded biochar-ZnO nanoparticle precursor was centrifuged at 7000r / min for 3min, and dried at 80°C to obtain 3.42g of the dried loaded biochar-ZnO nanoparticle precursor carbon airgel;

[0067] The dried loaded biochar-ZnO nanoparticle precursor carbon aerogel was calcined at 900 °C in anaerobic high temperature to obtain 3.02 g of biochar-ZnO nanoparticle composite catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com