A fuel-saving automatic egg breaking and frying device

An omelette and integrated technology, which is applied in frying pans, kitchen utensils, household utensils, etc., can solve the problems of safety threats to omeletters, small production volume, manpower omelette consumption of manpower and material resources, etc., to reduce personal safety threats, reduce Labor costs, the effect of reducing egg-breaking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

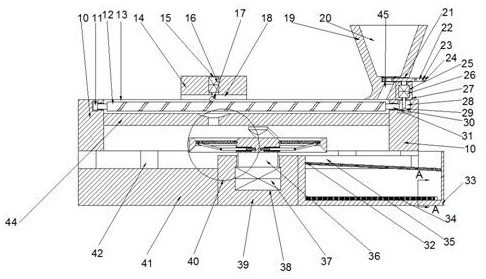

[0022] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

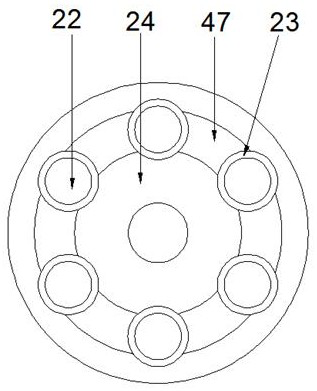

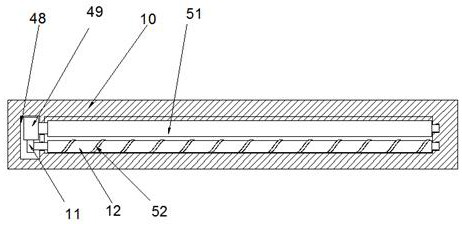

[0023] A fuel-saving integrated egg-cracking and frying device described in conjunction with accompanying drawings 1-8 includes an upper base 10 and a main base 41, and a sieve plate motor box 27 is fixedly installed on the upper end of the upper base 10, and the sieve plate The motor box 27 is provided with a sieve plate motor cavity 25 with an opening upwards and downwards, and a sieve plate motor 26 with an upward and downward rotating shaft is fixedly installed in the sieve plate motor cavity 25, and the upper end of the sieve plate motor 26 is fixed. A sieve plate 24 is installed, and the sieve plate 24 is evenly provided with a sieve hole 22, and a buffer sponge 23 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com