Clausena lansium volatile oil microcapsule powder and preparation method thereof

A technology of volatile oil and micro-oil, which is applied in the field of flavors and fragrances, to achieve the effect of large-scale industrial continuous production, good repeatability and high yield of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

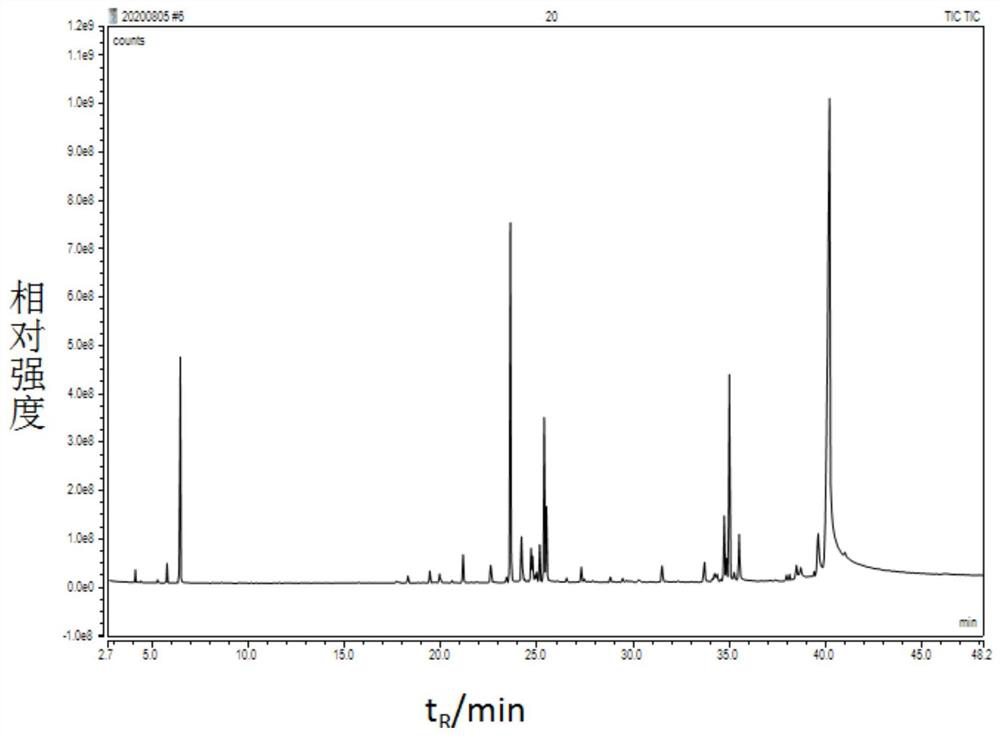

Image

Examples

Embodiment 1

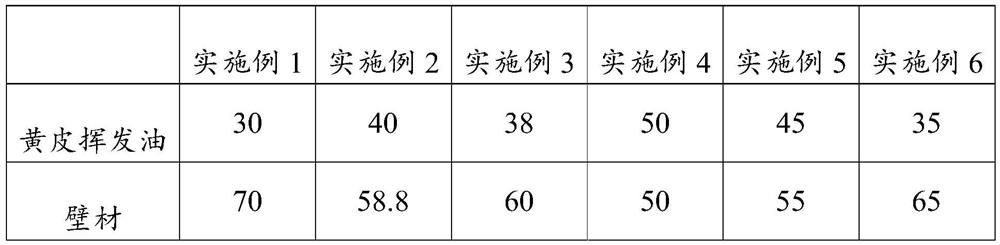

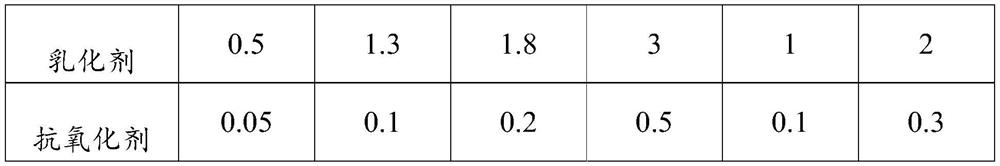

[0040] Embodiments After weighing the components according to Table 1 and Table 2, the preparation method of the microcapsule powder of the volatile oil of yellow skin described in Example 1 comprises the following steps:

[0041] (1) Prepare the water phase: add water at 70°C to the wall material, stir to dissolve, and stir for 30 minutes to obtain the water phase A with a mass concentration of solids of 50%;

[0042] (2) Prepare the oil phase: mix the emulsifier, antioxidant and volatile oil of wampum bark uniformly at 60°C to obtain the oil phase B;

[0043] (3) Emulsification: Add the oil phase B obtained in the step (2) to the water phase A obtained in the step (1), and stir at a rate of 30000 rpm and a stirring time of 40 min to obtain a coarse emulsion;

[0044] (4) Homogenization, spray drying: the coarse emulsion obtained in step (3) is homogenized, the pressure of homogenization is 30MPa, and the number of times of homogenization is 3 times, and the homogeneous liqui...

Embodiment 2

[0046] EXAMPLES After weighing the components according to Table 1 and Table 2, the preparation method of the microcapsule powder of yellow skin volatile oil described in Example 2 comprises the following steps:

[0047](1) Prepare the water phase: add water at 60°C to the wall material, stir to dissolve, and stir for 30 minutes to obtain the water phase A with a mass concentration of solids of 40%;

[0048] (2) Prepare the oil phase: mix the emulsifier, antioxidant and volatile oil of yellow bark uniformly at 40°C to obtain the oil phase B;

[0049] (3) Emulsification: Add the oil phase B obtained in step (2) to the water phase A obtained in step (1), and stir at a rate of 10000 rpm for 20 minutes to obtain a coarse emulsion;

[0050] (4) Homogenization, spray drying: the coarse emulsion obtained in step (3) is homogenized, the pressure of homogenization is 20MPa, and the number of times of homogenization is 2 times, the homogeneous liquid is incubated, and the temperature of...

Embodiment 3

[0052] Embodiment After weighing the components according to Table 1 and Table 2, the preparation method of the microcapsule powder of the volatile oil of yellow skin described in Example 3 comprises the following steps:

[0053] (1) Prepare the water phase: add water at 65°C to the wall material, stir to dissolve, and stir for 30 minutes to obtain the water phase A with a solid content of 45%;

[0054] (2) Prepare the oil phase: mix the emulsifier, antioxidant and volatile oil of wampum bark uniformly at 50°C to obtain the oil phase B;

[0055] (3) Emulsification: Add the oil phase B obtained in step (2) to the water phase A obtained in step (1), and stir at a rate of 10000 rpm for 20 minutes to obtain a coarse emulsion;

[0056] (4) Homogenization, spray drying: the coarse emulsion obtained in step (3) is homogenized, the pressure of homogenization is 25MPa, and the number of times of homogenization is 2 times, the homogeneous liquid is incubated, and the temperature of insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com