Wafer cutting method

A cutting method and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as splits, wafer appearance damage, cracks, etc., and achieve the effect of precise control of cutting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

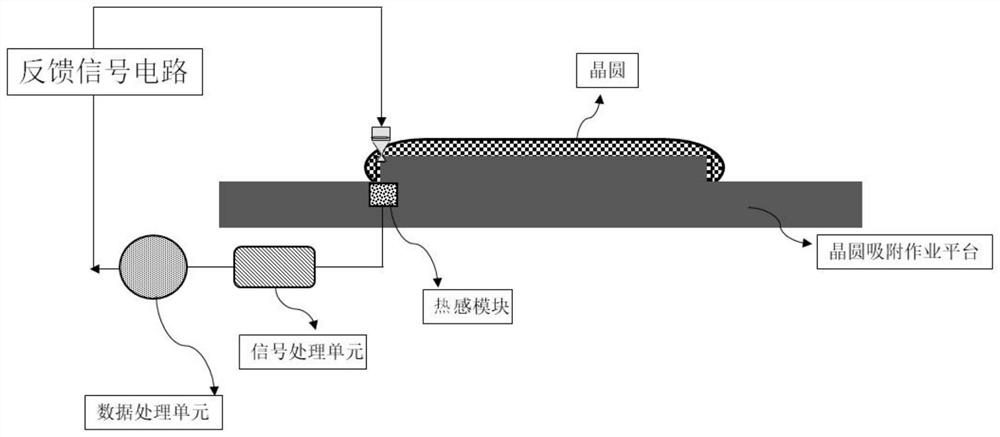

[0019] The wafer cutting method described in the present invention is mainly aimed at ring cutting of the wafer. According to the principle of cutting, due to the severe friction between the cutting head and the wafer in the cutting area, the heat in the cutting area accumulates, and the temperature continues to rise. After the wafer is cut through, the cutting head no longer rubs against the wafer, and the cutting area will appear sudden change in temperature. Such as figure 1 As shown, the entire cutting system includes a cutting head, which realizes circular cutting of the wafer, and also includes a thermal module, a signal processing unit, a data processing unit, and a feedback signal circuit. When the dicing unit ring-cuts the wafer, a thermal module is arranged under the wafer. Specifically, after the wafer is adsorbed on the cutting table, the thermal module is installed directly below the area with a radius of 130-150mm of the wafer. The thermal module and the cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com