Edge cutting machine special for wood veneer

An edge trimming machine and veneer technology, which is applied to wood processing appliances, sawing equipment, circular saws, etc., can solve the problems of low production efficiency, waste of wood, and increased burden on environmental protection, and achieves reduction of redundant burden, high production efficiency, and high production efficiency. Good cropping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

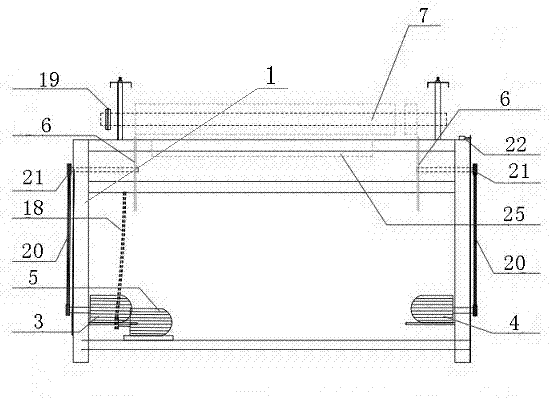

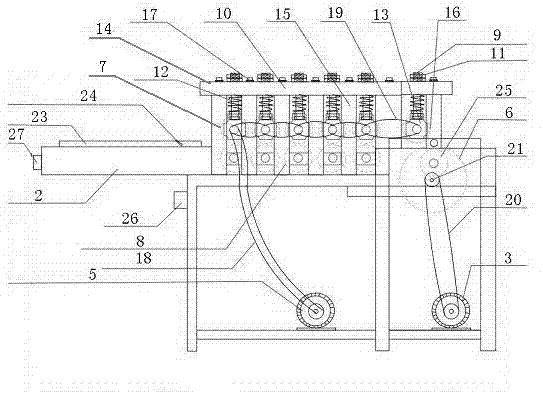

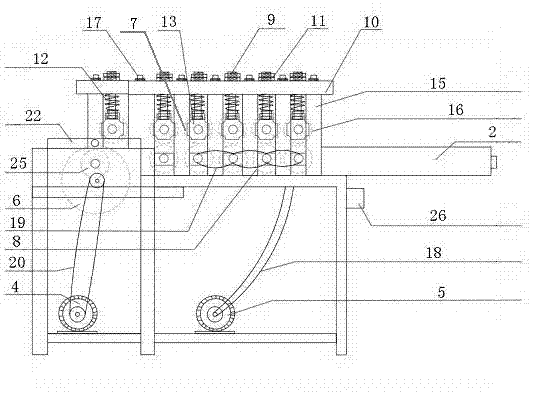

[0019] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises frame 1, and frame 1 rear part is provided with veneer and enters work platform 2, and frame 1 front two sides are respectively provided with left high-speed motor 3 and right high-speed motor 4, and frame 1 bottom is provided with adjustable speed motor 5. The left high-speed motor 3 and the right high-speed motor 4 are respectively connected with a saw blade 6, and the adjustable speed motor 5 is connected with several adjustable pressure rollers 7, and a pressure roller 8 is arranged under the adjustable pressure roller 7, and the adjustable pressure roller 7 is fixed by The rod 9 is fixed with the fixed rod assembly 10, the top of the fixed rod 9 is provided with an adjustment screw 11, and the fixed rod 9 is provided with a compression spring 12. The two ends of the adjustable pressure roller 7 are installed in the bearing sliding housing 13, the fixed rod asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com