Biosynthetic gene cluster of maduramicin compound and application of biosynthetic gene cluster

A technology of biosynthesis and madomecin, which is applied in the field of bioengineering and can solve the problems of biosynthetic gene clusters without madomecin compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0186] According to the method for preparing the maduramicin compound in the embodiment of the present invention, the maduramicin compound can be efficiently synthesized by using the aforementioned microorganisms for fermentation treatment. Then, through microbial wall breaking treatment and separation and purification treatment, the pure product of madomecin compound can be obtained efficiently, simply and at low cost.

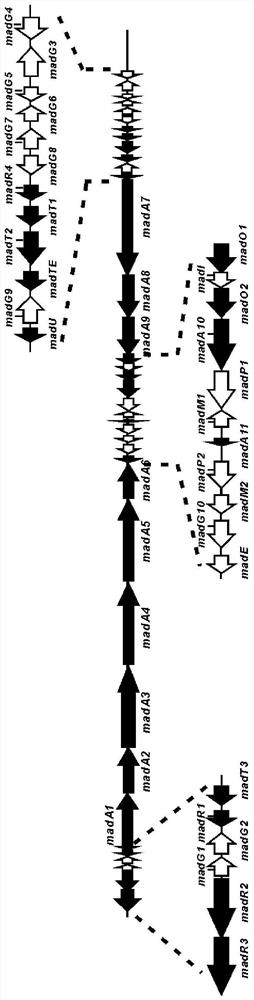

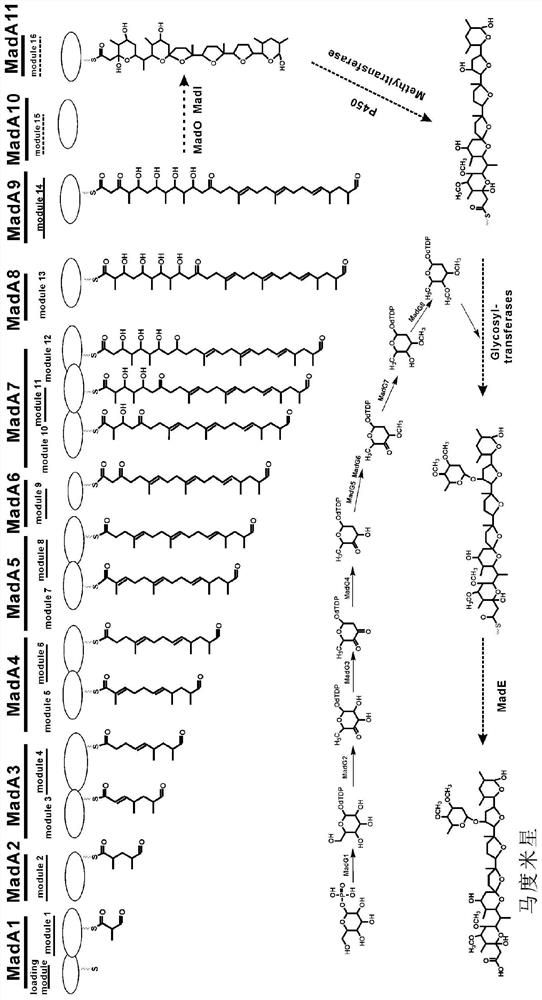

[0187] According to some embodiments of the present invention, through gene prediction, the biosynthetic pathway of the madomecin compound is deduced as follows: image 3 . On the one hand, the extended synthesis of propionyl-CoA and methylmalonyl-CoA is catalyzed by the polyketide synthesis gene cluster to finally form a long-chain fatty acid chain. The intermediate product of madomecin is obtained, on the other hand, the glycosyl is catalyzed by genes such as madG1, madG2, madG3, madG4, madG5, madG6, madG7 and madG8, and then the glycosyl is transferred to...

Embodiment 1

[0191] Inoculate Actinomadura sp.J1-007 actinomycetes on the SFM plate and culture for about three to four days. When colonies are formed in the SFM medium, pick a single colony and culture it in the seed medium for about three to four days, and inoculate it into the fermentation medium according to the amount of 1% (the composition of the fermentation medium is 0.4% [w / v] Corn Syrup, 6% [w / v] Dextrose, 2.4% [w / v] Feather Meal, 0.005% [w / v] Fe 2 (SO 4 ) 3 , 0.3% [w / v] NaCl, 0.015% [w / v] K 2 HPO 4 ,0.1%[w / v]CaCO 3 , pH7.2. )middle. Culture conditions: 30 degrees, 220 rotation speed, culture for 7 to 8 days.

[0192] At day 7 or 8, the cultures were extracted with methanol, and the extracts were detected by LC-MS, using a commercial maduramycin standard as a positive control. Such as Figure 4 As shown, Actinomadura sp. J1-007 has the same retention time as the madurmicin standard (ammonium salt compound: m / z=934.16). The compound was further confirmed to be a madurami...

Embodiment 2

[0194] Taking Actinomadura sp.J1-007 as the research object, the sequence information of the biosynthetic gene cluster of maduramicin compounds was studied, and the specific methods were as follows:

[0195] 1. DNA extraction

[0196] (1) Streptomyces subtype Actinomadura sp. J1-007 was inoculated in TSBY medium and cultured for 2 days, and the cells were collected at 7000 rpm×5 min.

[0197] (2) Discard the supernatant of the collected bacteria, add 30mL SET buffer, break up, and centrifuge at 7000rpm for 5 minutes. Discard the supernatant again, add 10mL SET buffer, break up the cells, add 300μL lysozyme (100mg / ml), bathe in water at 37℃ for 30-60 minutes, add 100μL proteinase K (100mg / ml), 10μL RNase (10mg / ml ), in a 37°C water bath for 30 minutes.

[0198] (3) Add 1.2 mL of 10% SDS to the mixture obtained in step (2), bathe in water at 55°C for 2 hours, shake gently every 15 minutes until the liquid gradually becomes clear.

[0199] (4) Add 4 mL of 5M Nacl to the liquid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com