System and method for extracting magnesium sulfate and sodium chloride from desulfurization wastewater

A technology for desulfurizing wastewater and magnesium sulfate, which is applied in the field of systems for extracting magnesium sulfate and sodium chloride, can solve the problems of aggravating smog, increasing coal consumption for power generation in power plants, affecting the utilization of fly ash in power plants, etc., so as to reduce the amount of sludge and increase resources. The effect of recycling and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

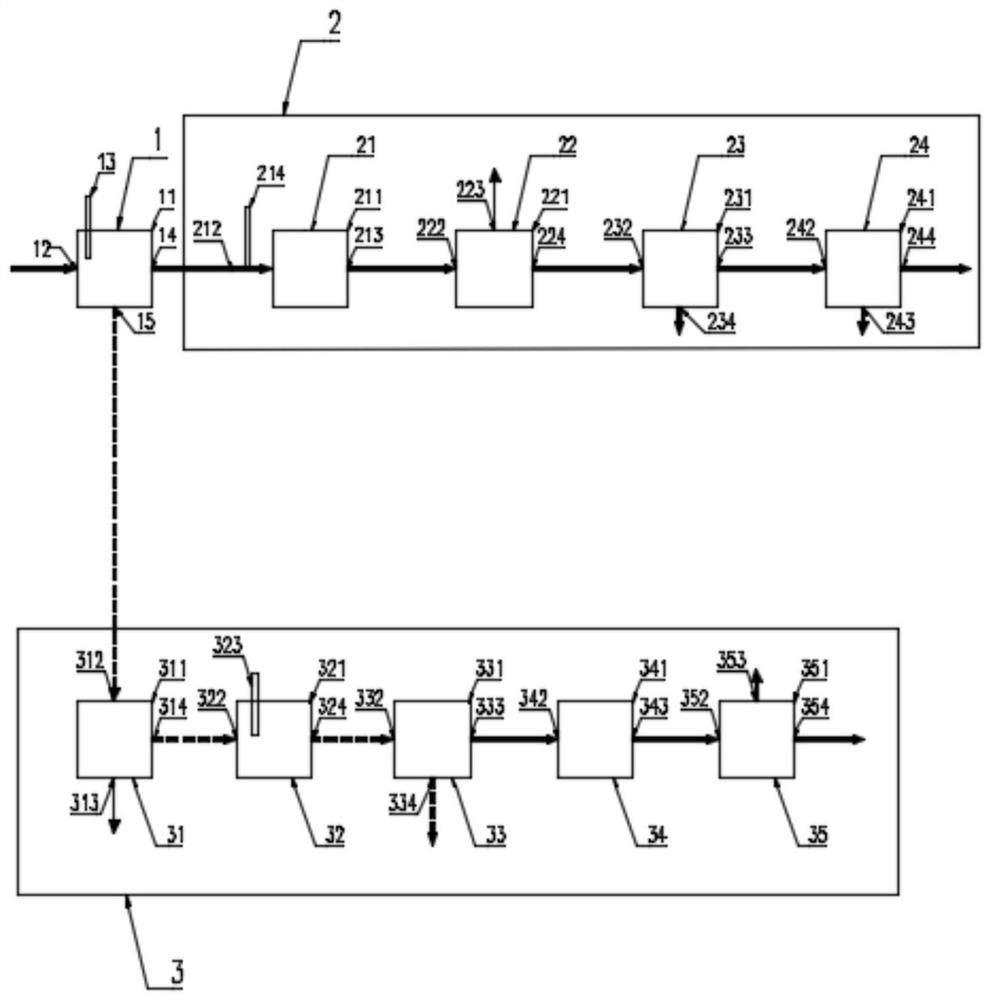

[0083] like figure 1 As shown, a system for extracting magnesium sulfate and sodium chloride from desulfurization wastewater includes a pretreatment device 1, a sodium chloride crystallization system 2 and a magnesium sulfate crystallization system 3 respectively connected to the pretreatment device 1;

[0084] Pretreatment device 1 comprises pretreatment device pool body 11, the pretreatment device water inlet 12 that is arranged on the pretreatment device pool body 11, the pretreatment device dosing port 13, is arranged on the pretreatment device pool body 11 and is positioned at the pretreatment device The pretreatment device supernatant liquid discharge port 14 on the opposite side of the water inlet 12 and the pretreatment device sludge discharge port 15 arranged at the bottom of the pretreatment device pool body 11, the pretreatment device dosing port 13 is used for dosing the incoming water The calcium and magnesium ions form the medicament for precipitation, and the po...

Embodiment 2

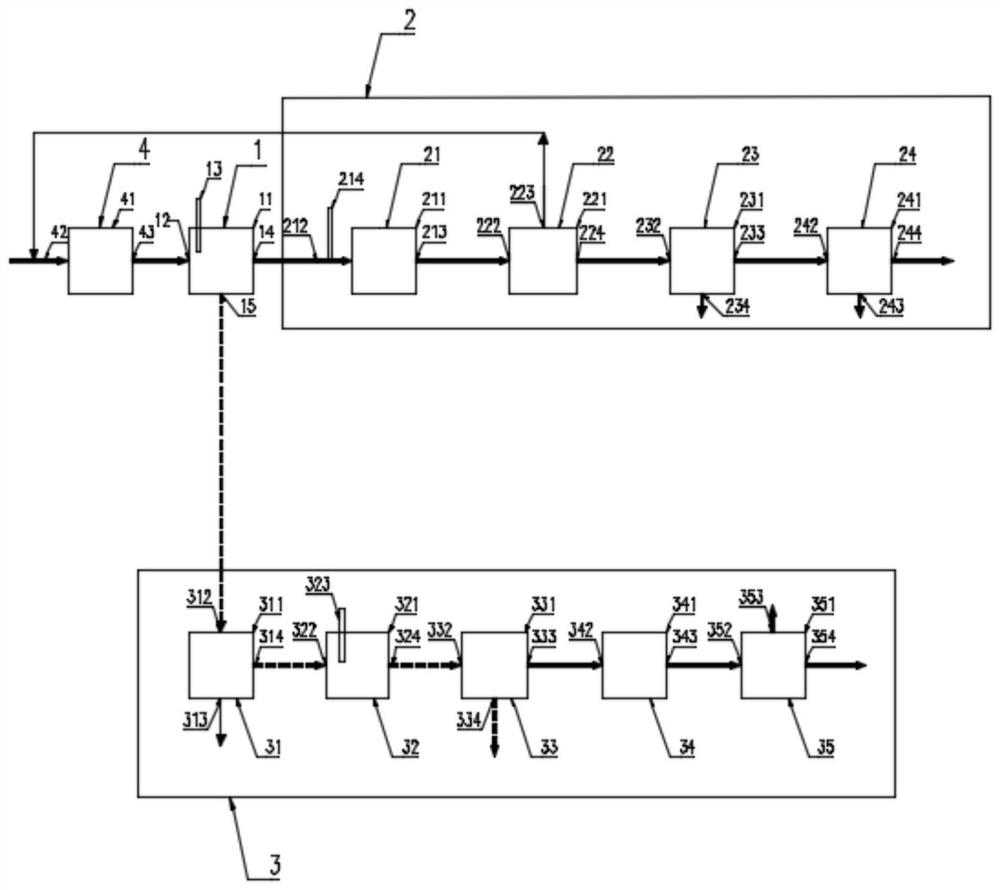

[0101] like figure 2 As shown, on the basis of Embodiment 1, a regulating pond 4 is also provided at the water inlet end of the pretreatment device 1, and the regulating pond 4 includes a regulating pond body 41, a regulating pond inlet pipe 42 arranged on the regulating pond body 41, The water outlet 43 of the water adjustment pool located on the body 41 of the water adjustment pool and located on the opposite side of the water inlet pipe 42 of the water adjustment pool;

[0102] The water inlet pipe 42 of the regulating tank is connected with the incoming water of the desulfurization wastewater, the water outlet 43 of the regulating tank is connected with the water inlet 12 of the pretreatment device, and the desulfurization wastewater enters the pretreatment device 1 after passing through the regulating tank 4;

[0103] The concentrated water port 223 of the nanofiltration and salt separation device is connected to the water inlet pipe 42 of the regulating tank.

Embodiment 3

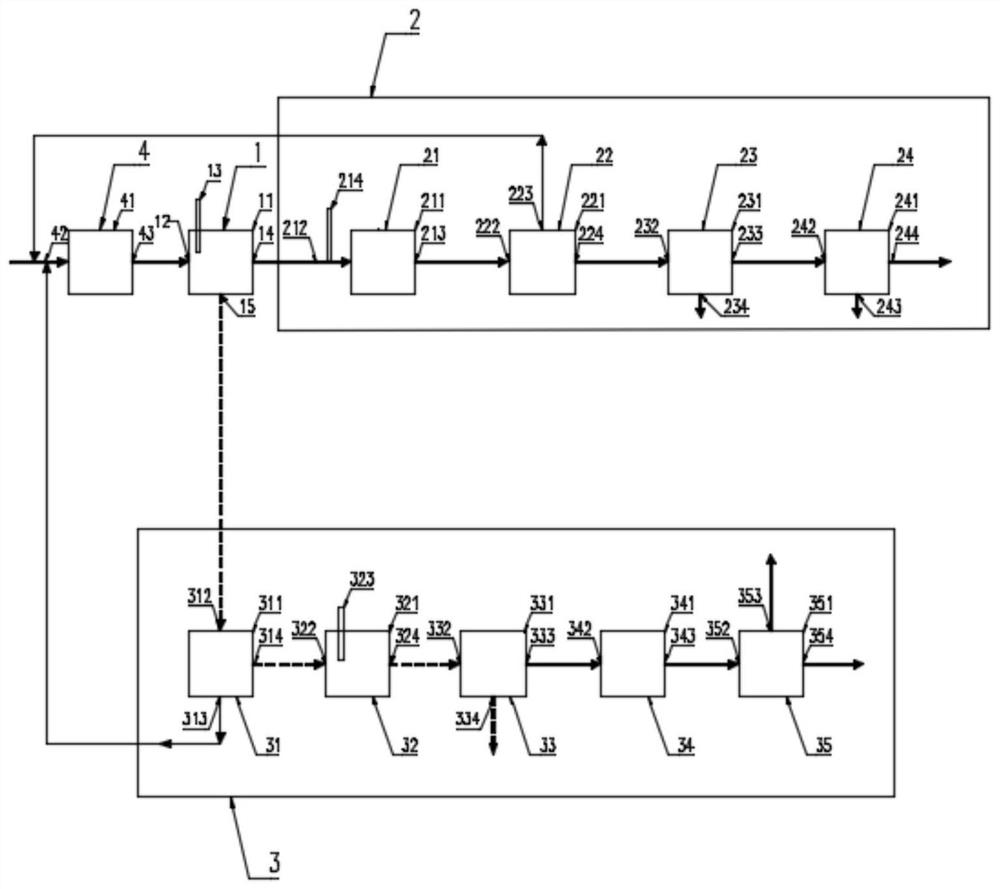

[0105] like image 3 As shown, on the basis of Embodiment 2, the discharge port 313 of the sludge dewatering device is connected to the water inlet pipe 42 of the regulating tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pores | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com