Iron-aluminum-carbon composite catalytic material, preparation method and organic wastewater degradation method

A catalytic material, carbon composite technology, applied in catalyst activation/preparation, chemical instruments and methods, energy and wastewater treatment, etc., can solve problems such as unfavorable industrial production, difficult active component loading, complex operation, etc. , the effect of high repeated use and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of iron-aluminum-carbon composite catalytic material of the present invention, its steps are as follows:

[0028] S1 First, dissolve the ferric compound, trivalent aluminum compound and glucose into ultrapure water to form three solutions; the ferric compound is ferric chloride hydrate, ferric nitrate hydrate or ferric nitrate hydrate; The aluminum compound is selected from aluminum chloride hydrate, aluminum nitrate hydrate or aluminum nitrate hydrate; the concentration of the ferric compound and the trivalent aluminum compound aqueous solution is 0.2-0.8mol / L; the concentration of the glucose solution is 6g / L;

[0029] S2 Add the ferric compound solution and the trivalent aluminum compound solution dropwise to the glucose solution at a rate of 1-10mL / min; slowly add the ferric compound solution and the trivalent aluminum compound solution into the glucose solution at the same time and stir with a stirring device , the stirring speed is 600-1000r...

Embodiment 1

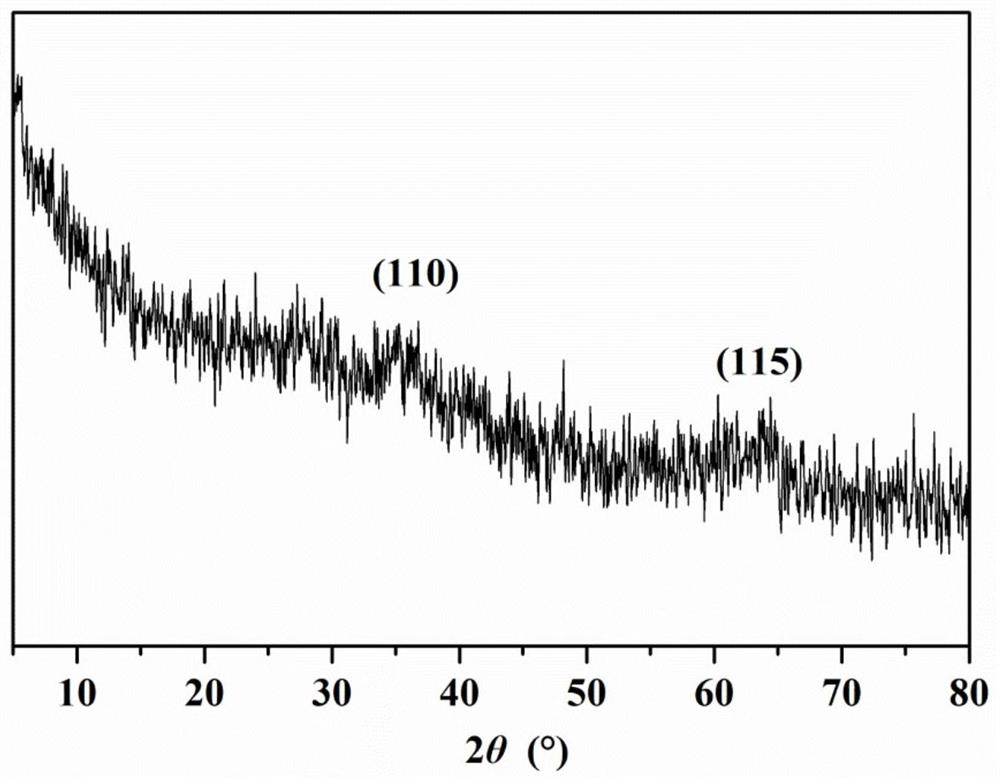

[0035] Such as figure 1 Shown, a kind of method for preparing iron-aluminum-carbon composite catalytic material of the present invention comprises the following steps:

[0036] 1) Weigh 8.25g (20mmol) ferric nitrate nonahydrate and dissolve it in 30mL ultrapure water; weigh 1.25g aluminum chloride hexahydrate (5mmol) and place it in 20mL ultrapure water; weigh 10g glucose and dissolve it in 20mL ultrapure water;

[0037] 2) slowly drop the above-mentioned ferric nitrate solution and aluminum chloride solution into the glucose solution at the same time, the dropping rate is 2mL / min, magnetically stir for 2h, and the stirring speed is 800r / min;

[0038] 3) Use 1.5mol / L sodium hydroxide solution to adjust the pH of the above solution to 8.0, stir magnetically for 2 hours, and the stirring speed is 800r / min;

[0039] 4) Transfer the above mixed solution to a 200mL hydrothermal reaction kettle, and place it in a hydrothermal reaction at 180°C for 24 hours; then separate the preci...

Embodiment 2

[0047] A method for preparing an iron-aluminum-carbon composite catalytic material, comprising the following steps:

[0048] 1) Weigh 8.25g (20mmol) ferric nitrate nonahydrate and dissolve it in 60mL ultrapure water; weigh 1.25g aluminum chloride hexahydrate (5mmol) and place it in 25mL ultrapure water; weigh 10g glucose and dissolve it in 30mL ultrapure water;

[0049] 2) Slowly drop the above-mentioned ferric nitrate solution and aluminum chloride solution into the glucose solution at the same time, the dropping rate is 2mL / min, magnetically stir for 2h, and the stirring speed is 600r / min;

[0050] 3) Use 3mol / L sodium hydroxide solution to adjust the pH of the above solution to 7.5, stir magnetically for 2 hours, and the stirring speed is 600r / min;

[0051] 4) Transfer the above mixed solution to a 200mL hydrothermal reaction kettle, and place it in a hydrothermal reaction at 180°C for 24 hours; then separate the precipitate by suction filtration, and wash it several times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com