High-voltage direct-current bus bar power control method in airplane high-voltage direct-current power supply system

A technology of high-voltage direct current and power supply system, applied in parallel operation of direct current power supplies, direct current network circuit devices, electrical components, etc., can solve problems such as complicated external hardware wiring, difficult control algorithm improvement and optimization, etc. The effect of reliable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

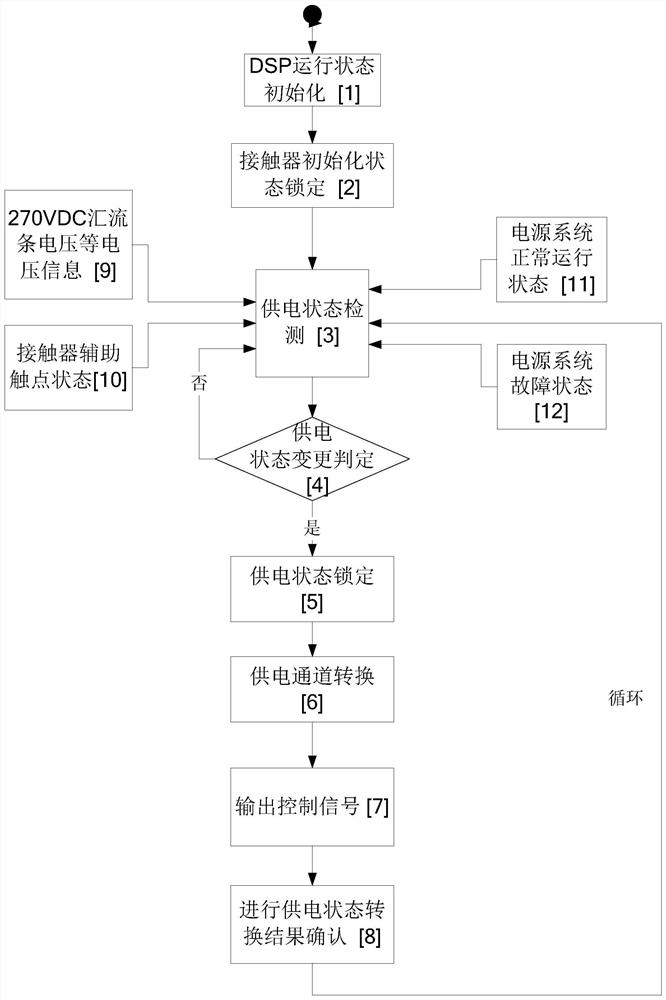

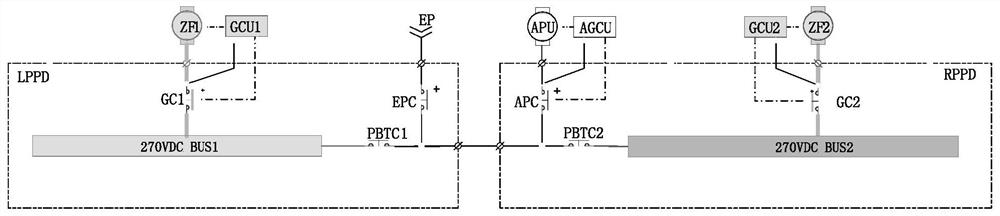

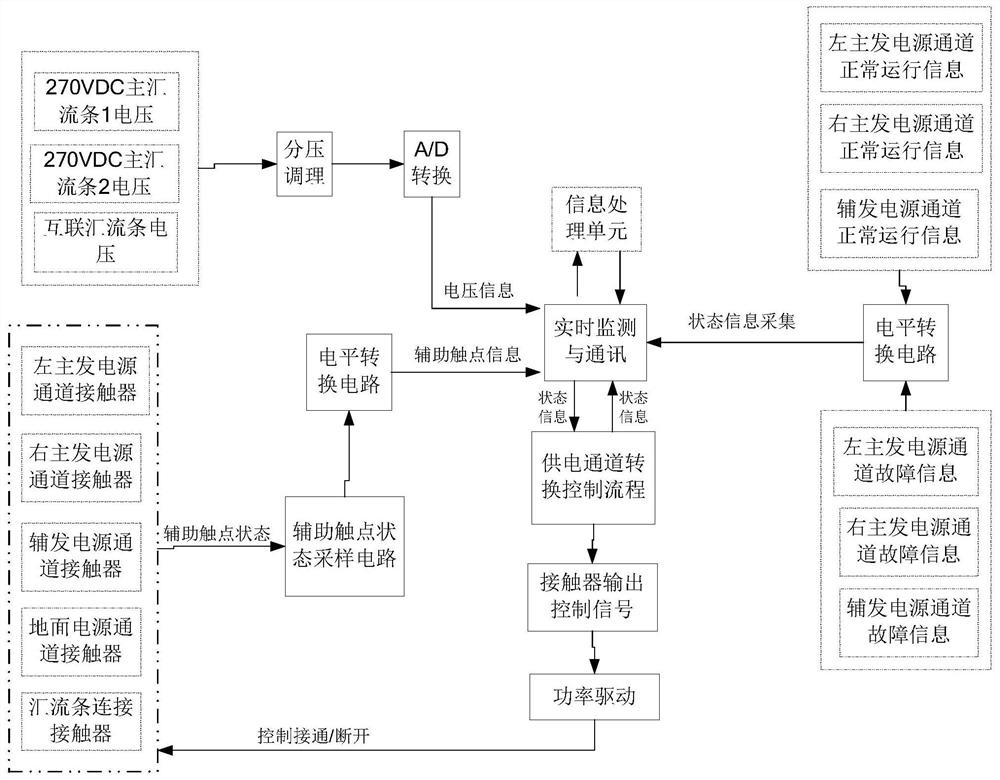

[0026] The power control method of the high-voltage DC bus bar proposed by the present invention needs to be realized based on relevant hardware, including a bus bar voltage / interconnected bus bar voltage sampling circuit, a signal conditioning circuit, a power system operating normal state and a fault state signal sampling circuit, and an auxiliary contactor contactor. Point sampling circuit, A / D conversion circuit, level conversion circuit, DSP processing unit, communication unit, contactor drive circuit, etc.

[0027] The signal processing and information sampling of analog quantities such as bus voltage and interconnected bus voltage are realized through the bus voltage / interconnected bus voltage sampling circuit, signal conditioning circuit and A / D conversion circuit; through contactor auxiliary contact sampling circuit, power supply The signal sampling circuit of the normal state and fault state of the system and the level conversion circuit realize the discrete informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com