Agricultural rice airing device

A drying device and paddy technology, applied in the agricultural field, can solve the problems of increasing the workload of staff and inconvenient use, and achieve the effects of quick cleaning, avoiding random flying, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

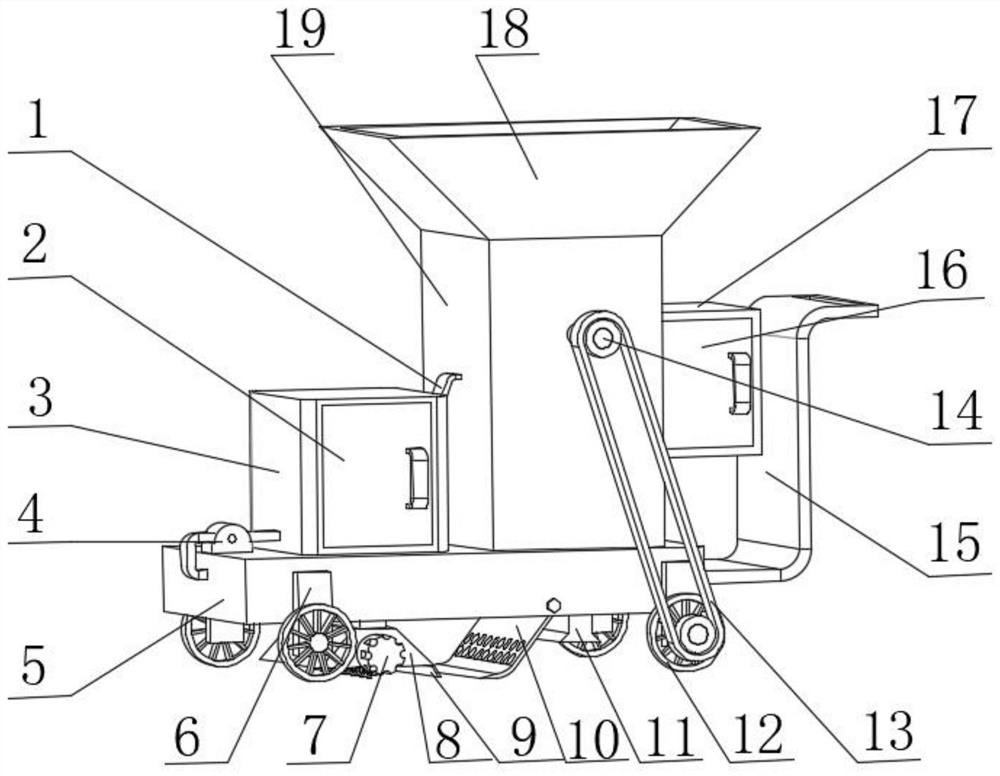

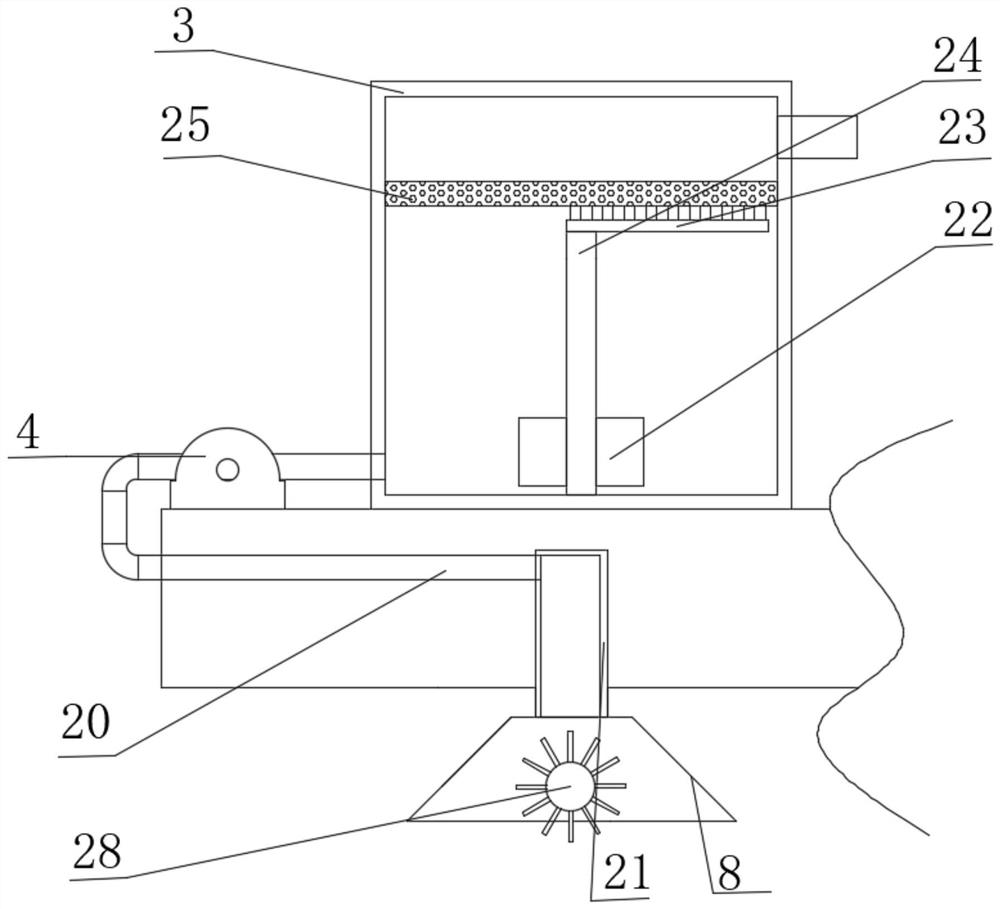

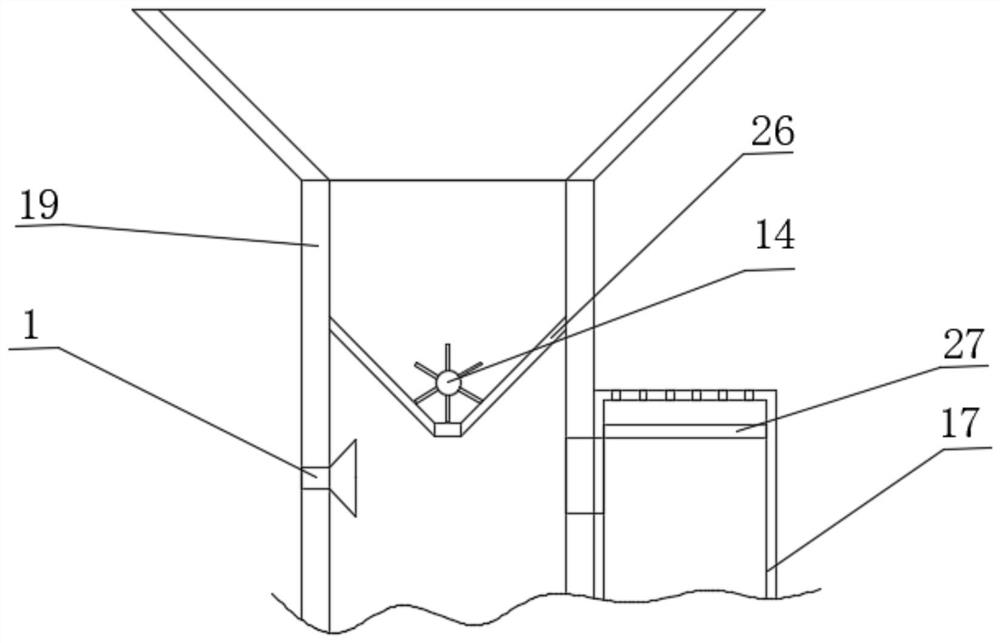

[0027] refer to Figure 1-4 , an agricultural rice drying device, comprising a base 5, the outer wall of the bottom of the base 5 is provided with a sliding groove, and the inner wall of the sliding groove is slidably connected with a sliding plate 29, the outer wall of one end of the base 5 is rotatably connected with a locking bolt, and the outer wall of the bottom of the sliding plate 29 is installed There is a shoveling plate 10, the outer wall of the top of the shoveling plate 10 is provided with discharge troughs distributed equidistantly, the outer wall of the top of the base 5 is equipped with a storage shell 19, and the outer wall of the top of the storage shell 19 is equipped with a hopper 18, one side of the outer wall of the top of the base 5 The first dust removal housing 3 is installed, and the second dust removal housing 17 is installed on one side outer wall of the storage housing 19 , the discharge pipe 11 is installed on the bottom outer wall of the storage ho...

Embodiment 2

[0032] refer to Figure 1-5 , a kind of agricultural paddy airing device, also comprises the triangular conical block 30 that equidistant distribution is installed on the inner wall of air inlet pipe 21 two ends.

[0033] Working principle: Compared with embodiment 1, the triangular conical block 30 arranged inside the air inlet pipe 21 can disperse the incoming wind, so that the air inlet bucket 8 can evenly enter the air, making the device more perfect.

[0034] The standard parts used in the present invention can all be purchased from the market, and the specific connection modes of each part all adopt conventional means such as bolts, rivets, and welding mature in the prior art, and machinery, parts and equipment all adopt conventional means in the prior art. model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com