Ditch cover plate for supporting underground transportation of railless rubber-tyred vehicle

A trackless rubber-tyred vehicle and ditch cover technology, which is applied in the sewer pipeline system, drainage, waterway system, etc., can solve the problem of not being able to meet the requirements of the rubber-tyred vehicle transportation support, not suitable for the transportation conditions of the trackless rubber-tyred vehicle, and the load-bearing is not enough to meet the requirements of the trackless vehicle. Problems such as rubber-tyred vehicle transportation brackets, to achieve the effect of saving transformation funds, saving transformation time, and speeding up transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

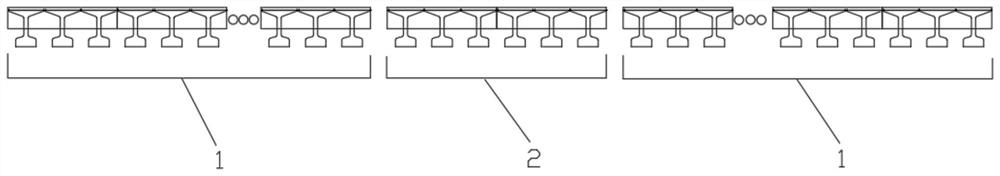

[0029] Such as figure 1 and 5 As shown, the ditch cover provided in this specific embodiment to support the underground transportation of trackless rubber-tyred vehicles includes a plurality of fixed cover groups 1 and a plurality of movable cover groups 2, and the fixed cover group 1 and the movable cover group 2 The number to be set is determined according to the length of the ditch in the reconstructed roadway. The fixed cover plate set 1 includes a plurality of cover plates 3 , and the movable cover plate set 2 includes several cover plates 3 .

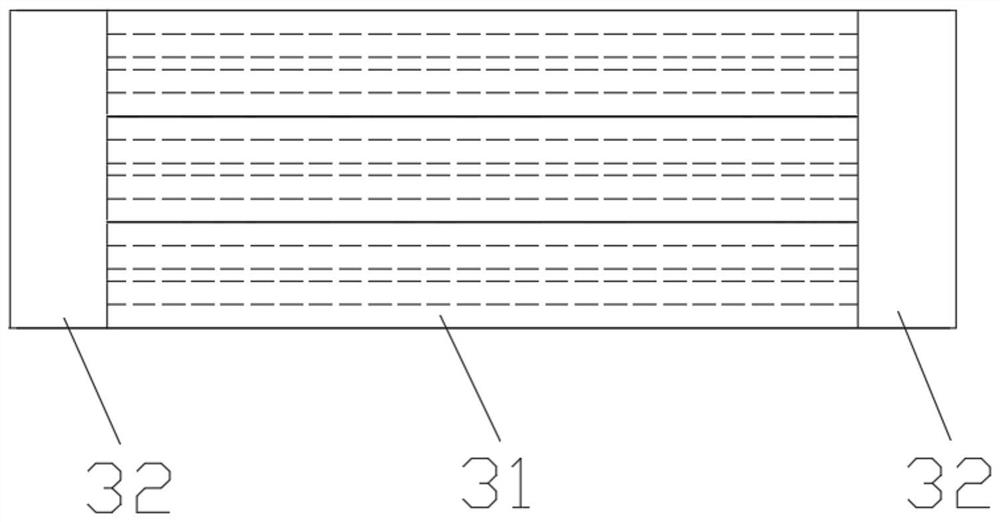

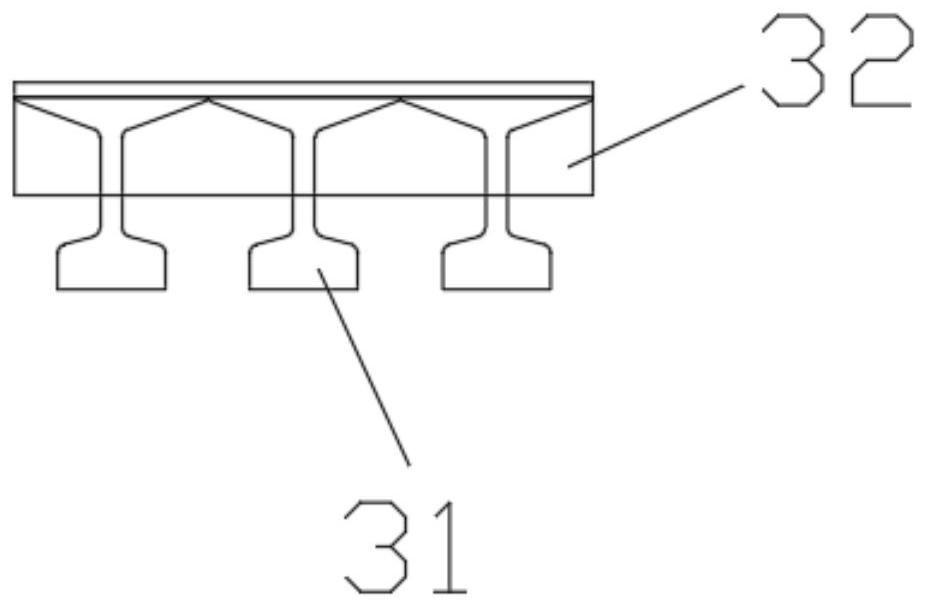

[0030] Such as Figure 2-4 As shown, the cover plate 3 is formed by connecting a plurality of ground rails 31 side by side. The ground rails 31 are the ground rails 31 disassembled in the trackless transformation of underground auxiliary transportation. The upper rail surface is difficult to be welded and connected, so the lower rail of the ground rail track 31 faces up as the upper surface of the cover plate 3, and the multipl...

Embodiment 2

[0041] The ditch cover plate supporting the underground transportation of trackless rubber-tyred vehicles in Example 1 is applied to the reconstruction of the underground track roadway of Jining No. 2 Coal Mine. The length of the roadway to be transformed is 300m, and the width of this roadway cannot meet the requirements of trackless rubber-tyred vehicle transportation. Requirements, such as according to the usual transformation method, after removing the width of the underground ditch, it is necessary to increase the width of the roadway by 1m, the height by 3m, and the cubic volume of the brush side to be 900m 3 , each labor cost is 145 yuan, and it takes about 4 months to rebuild a 300m roadway. There are 7 people in each shift, and a total labor cost of 365,000 yuan is required. The invented cover plate can be laid directly on the top of the underground ditch after preliminary processing and welding, and its load-bearing capacity is enough to meet the transportation of tra...

Embodiment 3

[0043] The ditch cover supporting the underground transportation of trackless rubber-tyred vehicles in Example 1 is applied to the transformation of another track roadway in Jining No. 2 Coal Mine. For wheeler transportation requirements, after removing the width of the underground ditch, it is necessary to increase the width of the roadway by 1m, the height by 3m, and the cubic volume of the brush side to 600m 3 , each labor cost is 145 yuan, 200m roadway reconstruction takes about 3 months, 7 people per shift, a total labor cost of 274,000 yuan is required, and material costs for anchor rods, anchoring agents, steel strips, etc. consume about 13,000 yuan. The invented cover plate can be laid directly on the top of the underground ditch after preliminary processing and welding, and its load-bearing capacity is enough to meet the transportation of trackless rubber-tyred vehicles. Using the ditch cover plate of the present invention to transform the roadway does not need to incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com