Variable angle cutting bit retaining assembly

A technology of cutting head and holder, applied in the direction of slitting machinery, cutting machinery, roads, etc., can solve the problem that the angle of attack cannot be changed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

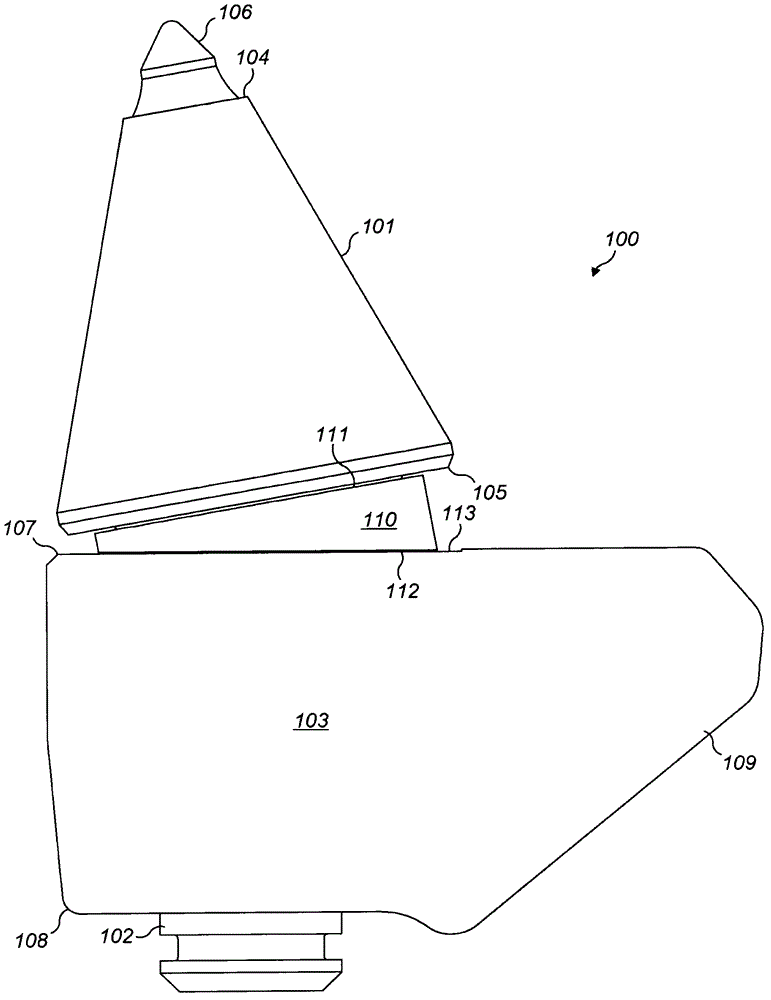

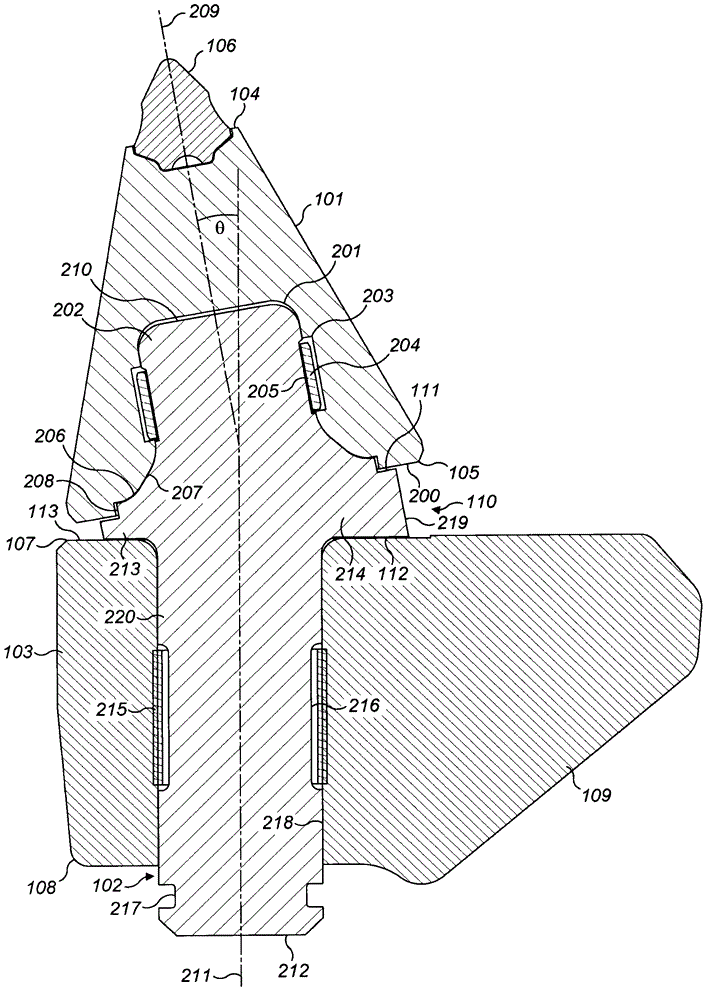

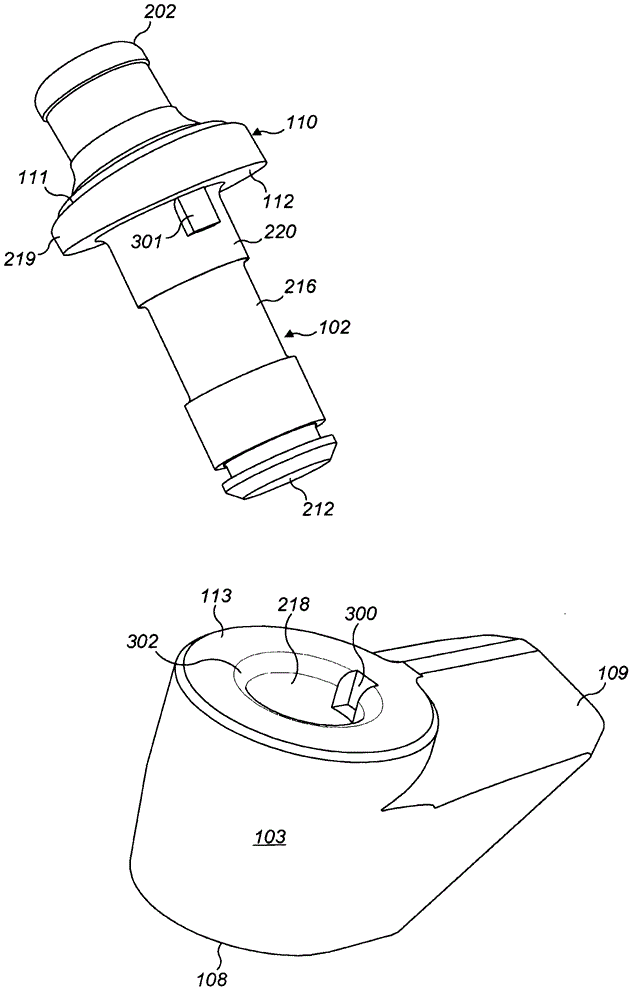

[0026] refer to figure 1 , the cutting head assembly 100 is adapted to be mounted at the outer surface of a rotatable cutting head (or drum) of a cutting machine (not shown). The assembly 100 comprises a cutting head 101 releasably and rotatably mounted at a cutting head holder 103 via an elongate adapter 102 which is correspondingly releasably mounted at a cutting head holder body 103 . The cutting head 101 includes a generally conical profile having a front end 104 to which a cutting tip 106 is mounted and a rear end 105 mounted at a front end 107 of a holder body 103 . The stand body 103 is mounted at the cutting head (or drum) via a mounting flange 109 protruding laterally from one side of the stand body 103 . Shoulder 110 projects radially outward from adapter 102 and includes a generally wedge-shaped configuration. The shoulder 110 includes: a forward facing annular surface 111 positioned to contact the cutting head rear end 105; and a rearward facing annular surface 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com