Low-temperature plasma coal or biomass gasification system and method

A low-temperature plasma and gasification system technology, applied in the field of plasma coal or biomass gasification system, can solve the problems of high plasma power consumption, high tar content, large investment cost, etc., and achieve the effect of avoiding electrode ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

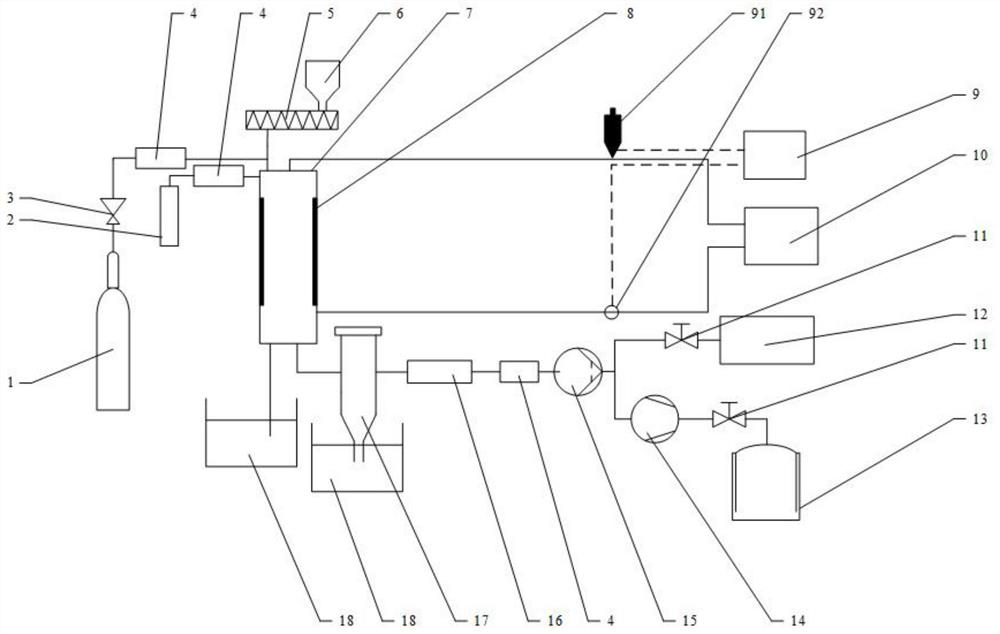

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0028] Such as figure 1 As shown, a low-temperature plasma coal or biomass gasification system includes a gasification reactor 7, a cyclone separator 17, a feeder 5 and a plasma generator, and the outlet end of the feeder 5 is connected to the gasification The feed port of the reactor 7 is connected, the feed port of the gasification reactor 7 is connected with the working gas device and the steam generator 2, the plasma generating end of the plasma generating device is arranged in the inner cavity of the gasification reactor 7, and the cyclone The feed port of separator 17 is connected to the discharge port of gasification reactor 7, the discharge port of cyclone separator 17 is connected with waste residue collector 18, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com