Demulsifying agent, carbon nanotube/hyperbranched polymer, preparation method of polymer and application of demulsifying agent

A technology of hyperbranched polymers and carbon nanotubes, applied in the fields of carbon nanotubes/hyperbranched polymers and their preparation, and demulsifiers, can solve the problems that cannot be used to deal with the difficulty of demulsification, such as water-in-oil, and reduce the oil-water interface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]A preparation method of carbon nanotube / hyperbranched polymer includes the following steps:

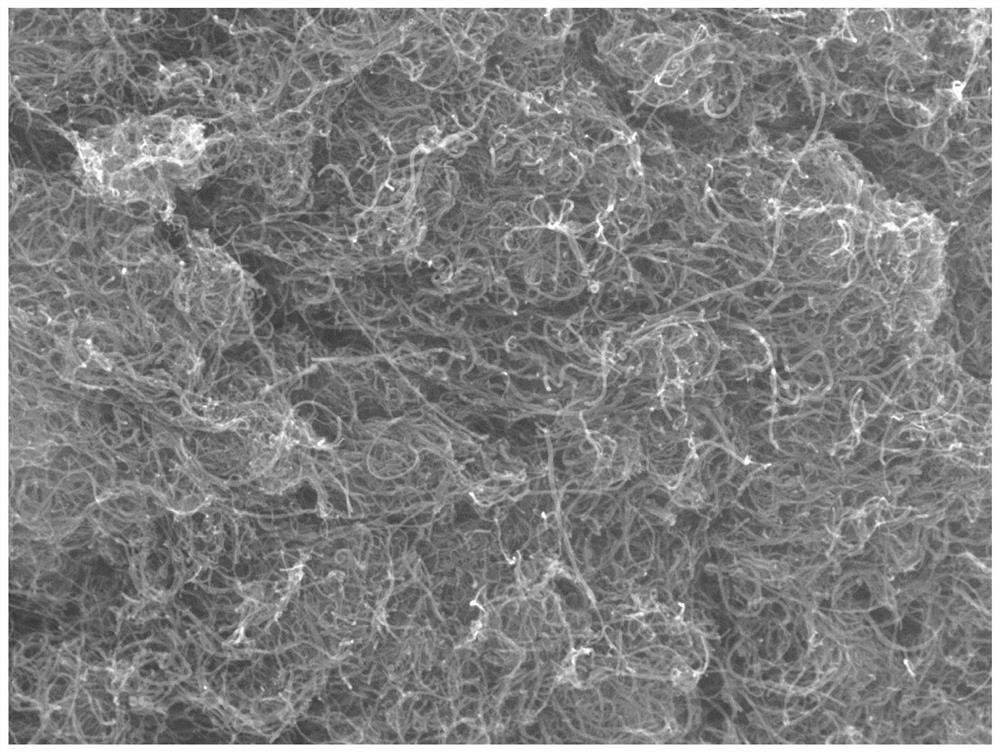

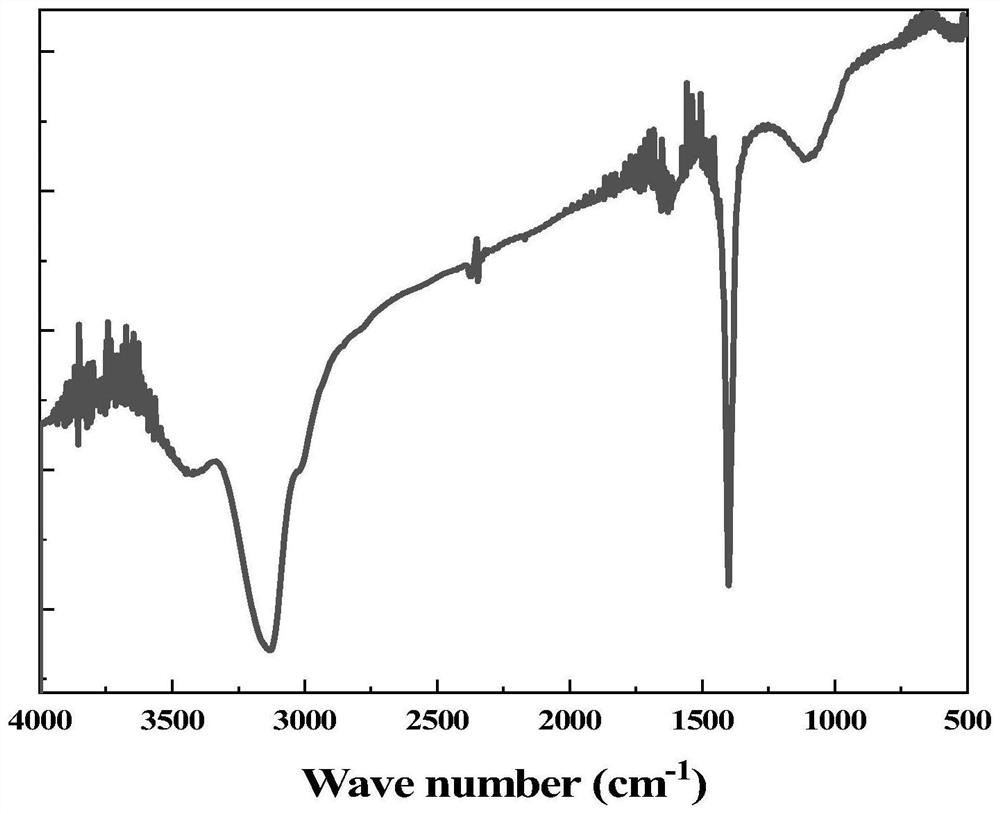

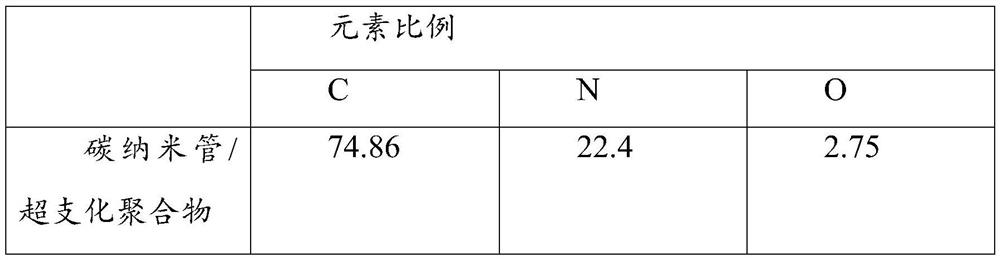

[0025]According to parts by weight, mix 5-15 parts of carbon nanotubes, 15-30 parts of sodium nitrite and 15-30 parts of ethylenediamine, and then add 20-25 parts of sulfuric acid with a concentration of 70% or more under stirring. React at 40-80°C for 1-5 hours to obtain amine-modified carbon nanotubes, then wash with organic solvent to obtain amine-modified carbon nanotubes, until the filtrate is colorless, and disperse the washed amine-modified carbon nanotubes in water. Then it is dried by centrifugation and washing with distilled water until pH=7; wherein, the carbon nanotubes are multi-walled carbon nanotubes, with a purity of >95%, a diameter of 8-15 nm, and a length of 30-50 μm; The solvent is preferably N,N-dimethylformamide;

[0026]Mix the amine-modified carbon nanotubes, ethylenediamine and methyl acrylate according to the mass ratio (10-30): (1-3): (1-7), and then mix them in a...

Embodiment 1

[0033]This embodiment provides a carbon nanotube / hyperbranched polymer demulsifier for W / O emulsion, and the demulsifier is obtained by the following steps:

[0034]Calculated in parts by weight, 10 parts by weight of carbon nanotubes, 23 parts by weight of sodium nitrite and 22.5 parts by weight of ethylenediamine are uniformly mixed to obtain solution I; 21 parts by weight of concentrated sulfuric acid with a concentration of 75% are added dropwise to the above solution I In the medium, the reaction was carried out at 60°C for 1 hour under stirring, and then the modified carbon nanotubes were washed with N,N-dimethylformamide until the filtrate was colorless. The modified carbon nanotubes are dispersed in water, then centrifuged and washed with distilled water until pH=7, and then dried to obtain the amine modified carbon nanotubes.

[0035]The amine-modified carbon nanotubes, ethylenediamine and methyl acrylate are mixed uniformly according to a mass ratio of 10:1:7 to obtain mixture I...

Embodiment 2

[0043]This embodiment provides a carbon nanotube / hyperbranched polymer demulsifier for W / O emulsion, and the demulsifier is obtained by the following steps:

[0044]Calculated in parts by weight, 15 parts by weight of carbon nanotubes, 30 parts by weight of sodium nitrite and 30 parts by weight of ethylenediamine are uniformly mixed to obtain solution I; 25 parts by weight of concentrated sulfuric acid with a concentration of 75% are added dropwise to the above solution I In the medium, the reaction was carried out at 50°C for 5 hours under stirring, and then the modified carbon nanotubes were washed with N,N-dimethylformamide until the filtrate was colorless. The modified carbon nanotubes are dispersed in water, then centrifuged and washed with distilled water until pH=7, and then dried to obtain the amine modified carbon nanotubes.

[0045]The amine-modified carbon nanotubes, ethylenediamine, and methyl acrylate were mixed uniformly according to a mass ratio of 15:2:5 to obtain mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com