A method for rapidly synthesizing high-titanium-content titanium-silicon molecular sieve ts-1 under normal pressure using crystallization mother liquor

A titanium-silicon molecular sieve, TS-1 technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, crystalline aluminosilicate zeolites, etc., to achieve the effects of increasing titanium content, avoiding pollution, and reducing the cost of synthetic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

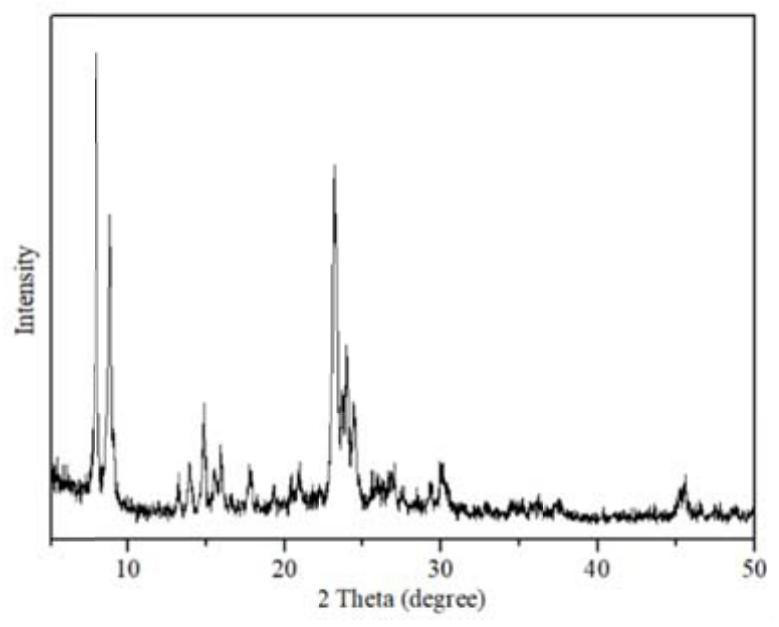

[0037] Inject 0.378 g of butyl titanate into a glass vial filled with 19.2 g of absolute ethanol and ultrasonically mix. Gained mixed liquid is added to 3.0g white carbon black (amorphous SiO 2 ) for 15 minutes and dried in a vacuum oven. Then add 12.0 g of tetrapropylammonium hydroxide aqueous solution with a concentration of 25 wt.% and grind it into a clear and transparent liquid. Pour the liquid into a self-made double-layer glass crystallizer with a volume of 25ml and a volume of 95°C circulating water. A reflux condenser is installed on the crystallizer. The resulting solid was isolated by ultracentrifugation. The obtained solid was dried and calcined in air at 500° C. for 4 hours to measure ultraviolet diffuse reflectance and XRD. The resulting 7.9g mother liquor was used for the next TS-1 molecular sieve synthesis.

Embodiment 2

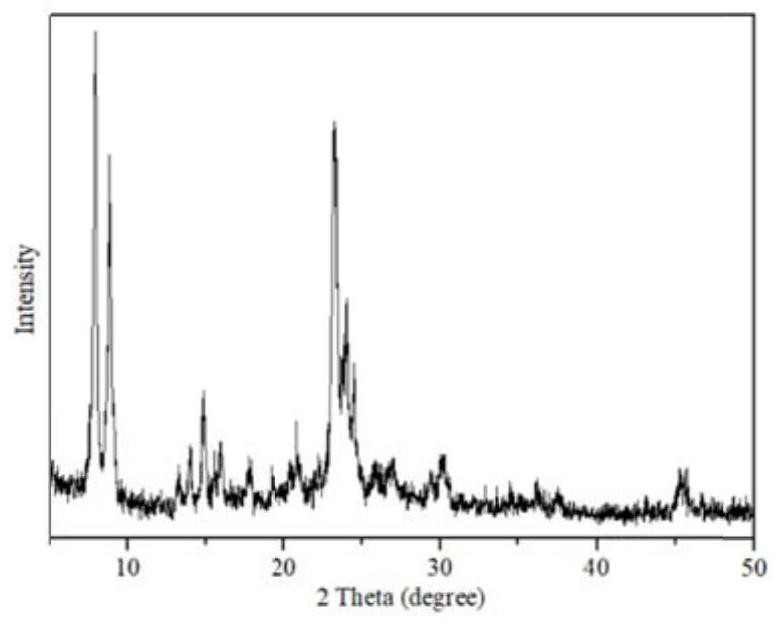

[0039] Example 1 was repeated, but instead of 3.0 g of silica and 0.378 g of butyl titanate in Example 1, 2.24 g of silica and 0.282 g of butyl titanate were used. The mixed aqueous solution of the tetrapropyl ammonium hydroxide of 7.9 gram mother liquors, 2.83 gram 25wt.% tetrapropyl ammonium hydroxide, 1.27 gram 50wt.% by embodiment 1 gained 12.0g concentration in the replacement embodiment 1 is 25wt.% aqueous solution of tetrapropylammonium hydroxide. Change the crystallization time to 30 hours. The obtained mother liquor of about 7.9 g is used for the next TS-1 molecular sieve synthesis.

Embodiment 3

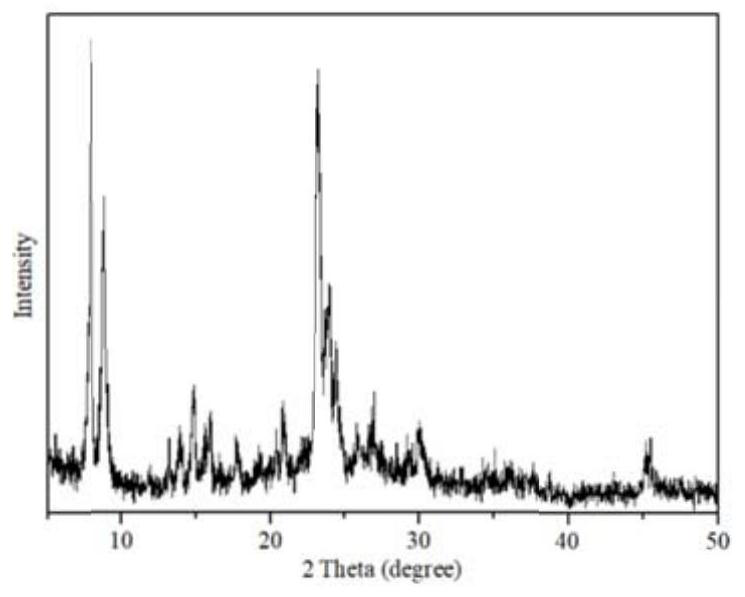

[0041] Example 2 was repeated, but the mother liquor obtained in Example 1 was replaced by the mother liquor obtained in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com