A heavy industrial machinery lifting platform

A lifting platform and machinery technology, applied in the direction of lifting device, lifting equipment safety device, etc., can solve the problems of the circumferential angle adjustment of the worktable, reduce the stability of the lifting platform, and move the center of gravity upward, so as to ensure normal operation and improve the application. range, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

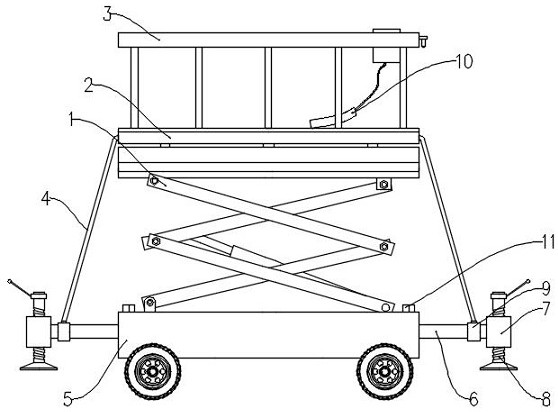

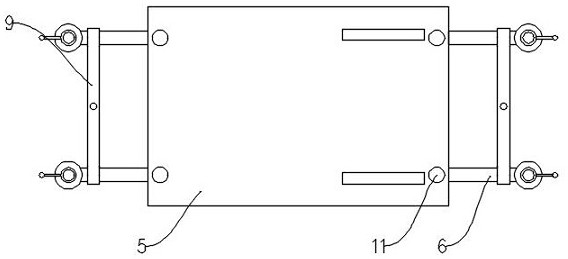

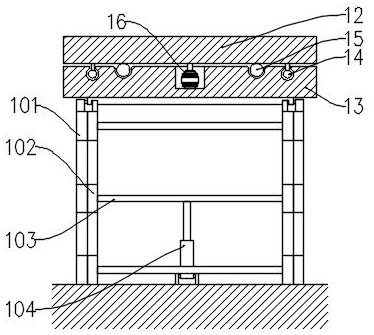

[0031] see Figure 1-6 , a heavy industrial mechanical lifting platform, including a jacking member main body 1, a plywood 12, a matching seat 13, a connecting seat 2 and a support seat 5, the jacking member main body 1 includes a folding rod one 101, a folding rod two 102 and a hydraulic rod 104, There are two groups of folding rod one 101 and folding rod two 102, and the two groups of folding rod one 101 and folding rod two 102 are rotatably connected by a connecting shaft 103, and the output end of the hydraulic rod 104 is movably connected with the outer wall of the connecting shaft 103. The tops of two groups of folding rods 101 and 102 are movably connected with the bottom of the mating seat 13, and the inner surface wall of the top of the mating seat 13 is fixedly installed with a driver 16. A slider 14 is fixedly installed, and the slider 14 is slidably connected with the inner surface wall of the mating seat 13 through a ring-shaped slot, and the inner surface wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com