Round rod polishing device

A technology of a round bar and a moving device, which is applied in the direction of a grinding drive device, a grinding machine, a grinding workpiece support, etc., can solve the problems of poor grinding effect of the round bar, and the quality cannot meet the working standards of grinding, and achieves a simple structure and integrated High-grade, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

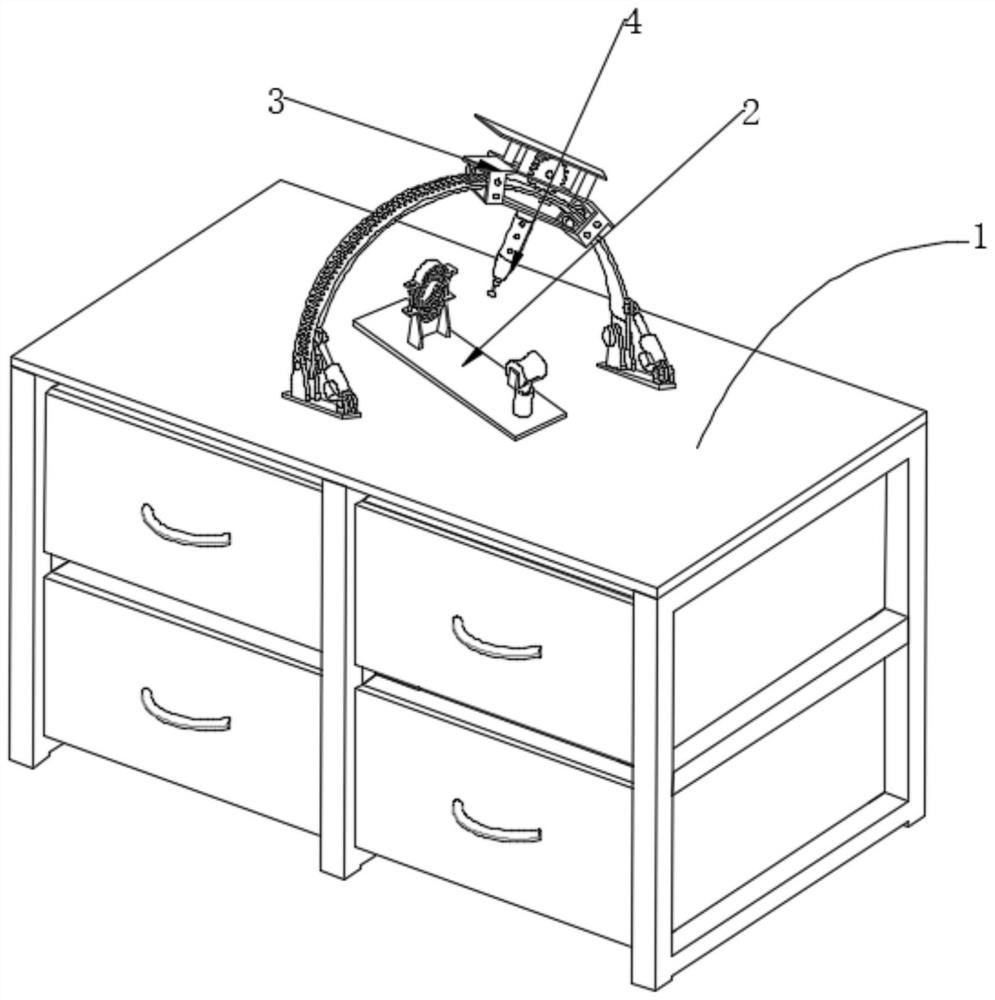

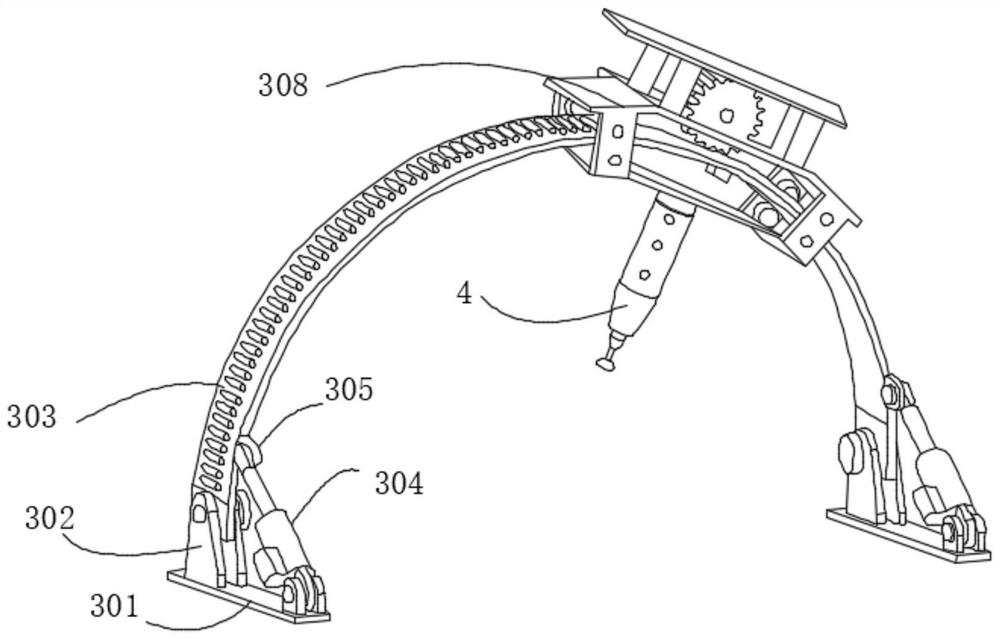

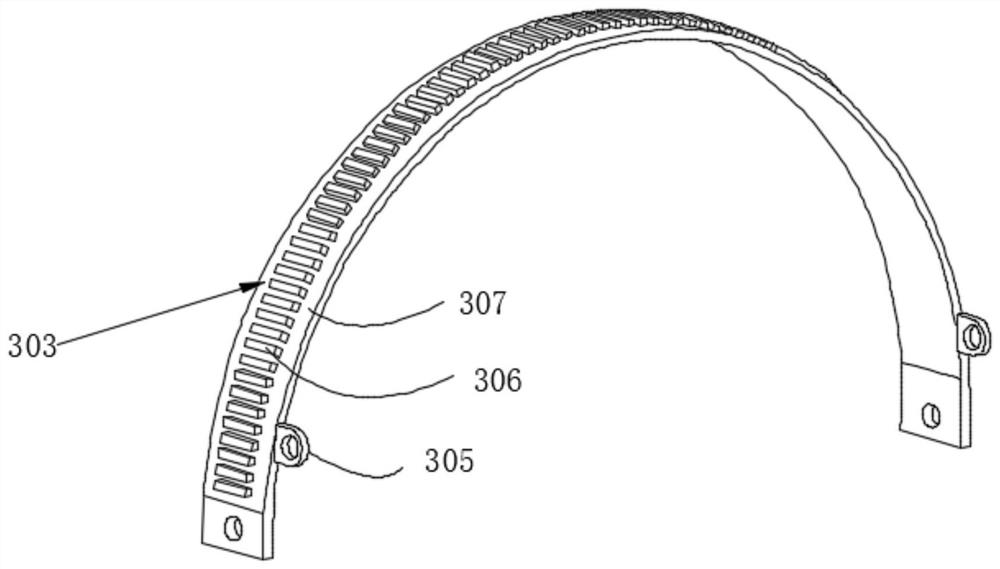

[0027] Embodiment: round rod grinding device, including workbench 1, such as figure 1 As shown, the workbench 1 is provided with a round pipe fixing device 2, and the workbench 1 is provided with an arc-shaped moving device 3. The arc-shaped moving device 3 is arranged above the round pipe fixing device 2. The arc-shaped moving device 3 is provided with a grinding Device 4; the arc-shaped mobile device 3 includes bases 301 fixed on both sides of the upper surface of the workbench 1, such as figure 2 and 3 As shown, the base 301 is provided with fixed ears 302, and an arc-shaped track 303 is arranged between the fixed ears 302 on both sides. The base 301 is provided with an electric push rod 304, and the side of the arc-shaped track 303 is provided with a rod Connecting ear 305, the protruding end of electric push rod 304 is connected with rod connecting ear 305, starts electric push rod, drives arc track to realize certain swing, also can polish some hemispherical workpieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com