Weld shape control and property control system for preventing collapse of molten pool based on electromagnetic field

An electromagnetic field and molten pool technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor weld formation, grain coarsening, poor arc stability, etc. Elimination of columnar crystals, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

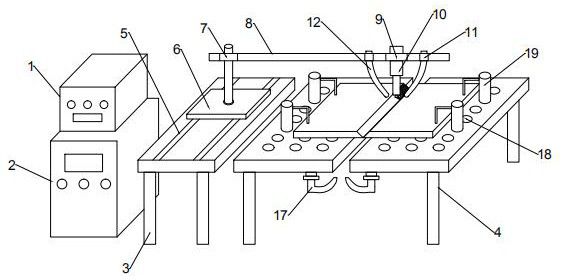

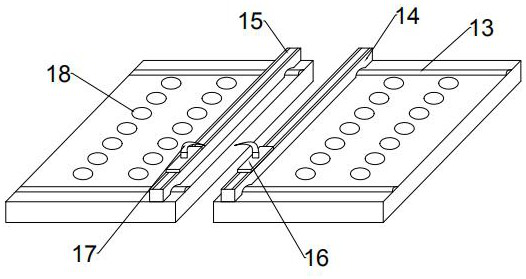

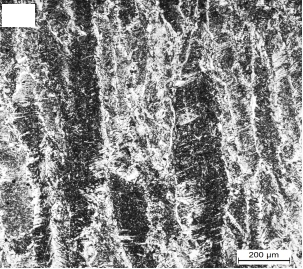

[0028] Example 1: In this example, the joints are welded without the action of a magnetic field. The length, width, and height of the flat sample are 300mm, 200mm, and 8mm respectively. Specifically, the flat sample is firstly polished with an angle grinder to remove oxidation on the surface of the sample. Use acetone to scrub the sample, then adjust the angle of the sample and fix it on the second workbench 4, adjust the arc voltage of the welding power source 2 to 22~26V, and the welding current to 210~290A , the moving speed of the moving car 6 is 210-250mm / min, the first magnetic pole and the welding torch body 10 are placed in the area to be welded 8-10mm, Ar protection is used, the gas pressure is 0.35MPa, the gas flow rate is 15L / min, after welding is completed, cut off Welding power supply 2, turn off the magnetic field power supply 1, and obtain a welded joint, wherein the microstructure of the weld seam is as follows image 3 , the surface morphology is as Figure 5...

Embodiment 2

[0029]Embodiment 2: In this embodiment, the joint is welded under the action of a magnetic field. The length, width and height of the flat sample are 300mm, 200mm and 8mm respectively. Specifically, the flat sample is firstly polished with an angle grinder to remove oxidation on the surface of the sample objects and impurities, leaking metallic luster, use acetone to scrub the sample, then place the sample on the second workbench 4, place the weld to be welded in the middle, adjust the front excitation current 1-4A in the magnetic field power supply 1, the front The frequency f of the alternating magnetic field is 4Hz, and the duty ratio is 50%; the excitation current at the back is 3-6A, and the frequency f of the alternating magnetic field at the back is 7Hz, and the duty ratio is 50%. Wherein, the arc voltage is 22~26V, the welding current is 210~290A, the traveling speed of the moving trolley 6 is 210-250mm / min, the first magnetic pole and the welding torch body 10 are plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com