A kind of tungsten bronze pure phase room temperature multiferroic ceramics and its preparation method

A technology of room temperature multiferroic and multiferroic ceramics, applied in the field of tungsten bronze pure-phase room temperature multiferroic ceramics and its preparation, can solve the problems of poor ferromagnetism, difficulty in obtaining pure phase, and unfavorable improvement of ferromagnetism , to achieve the effect of short sintering time, low cost, uniform and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 Electronic-grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and they are milled with high-energy balls in deionized water for 4 hours. After drying, they are heated at 1150 o C for 4 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in deionized water for 2 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder The body was pressed into a BSFN green body under 100MPa. After debinding the BSFN body, at 1250 o C microwave sintering method (2.45GHz) heat preservation for 30 minutes, then cool to room temperature with the furnace.

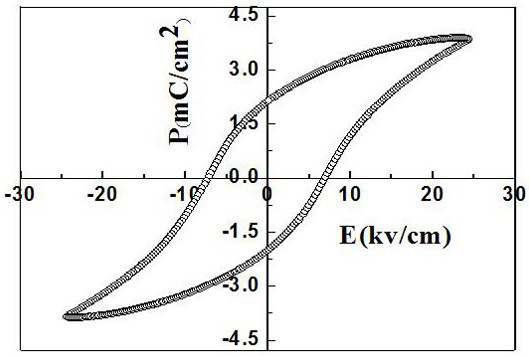

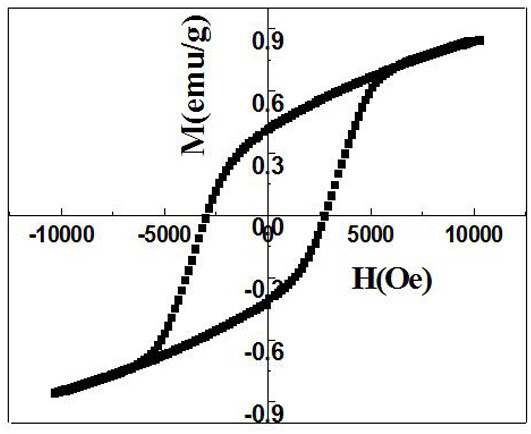

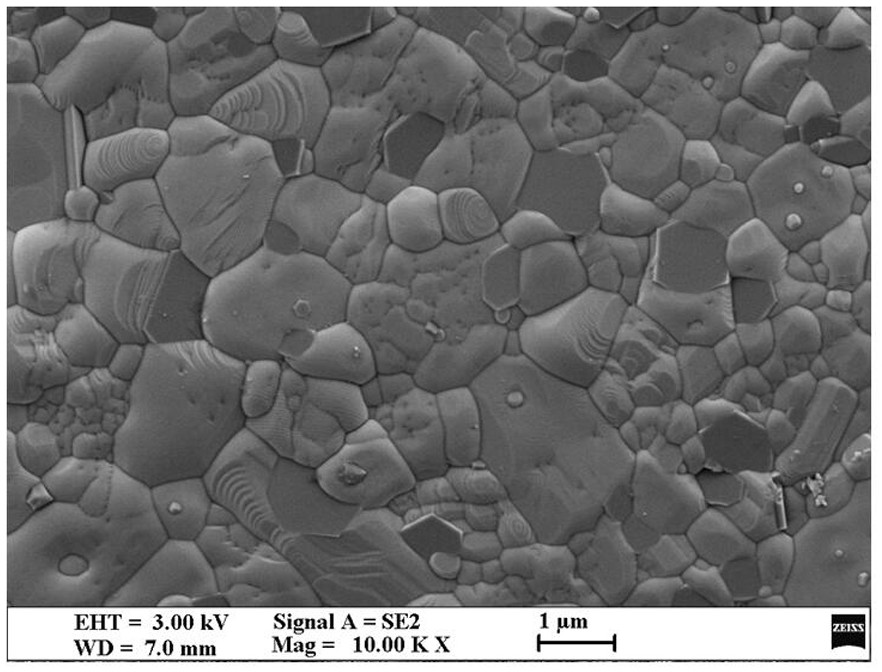

[0023] The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed g...

Embodiment 2

[0025] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 Electronic-grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and they are high-energy ball milled in alcohol for 6 hours. After drying, they are heated at 1150 o C for 2 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in alcohol for 2 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder was Pressed into BSFN body under 150MPa. After debinding the BSFN body, at 1250 o C microwave sintering method (2.45GHz) heat preservation for 30 minutes, then cool to room temperature with the furnace.

[0026] The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed grains with a size not exceeding 2 micro...

Embodiment 3

[0028] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 The electronic grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and the high-energy ball milling in deionized water is carried out for 16 hours. o C for 4 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in deionized water for 4 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder The body was pressed into a BSFN green body under 100MPa. After debinding the BSFN body, at 1250 o C Microwave sintering method (2.45GHz) heat preservation for 15 minutes, and cool to room temperature with the furnace. The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed grains with a size not exceeding 2 micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com