Green cyclic utilization method of honeycomb type denitration catalyst

A denitration catalyst and honeycomb technology, which are applied in the field of green recycling of honeycomb denitration catalysts, can solve the problems of large water consumption, large amount of waste water, high energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

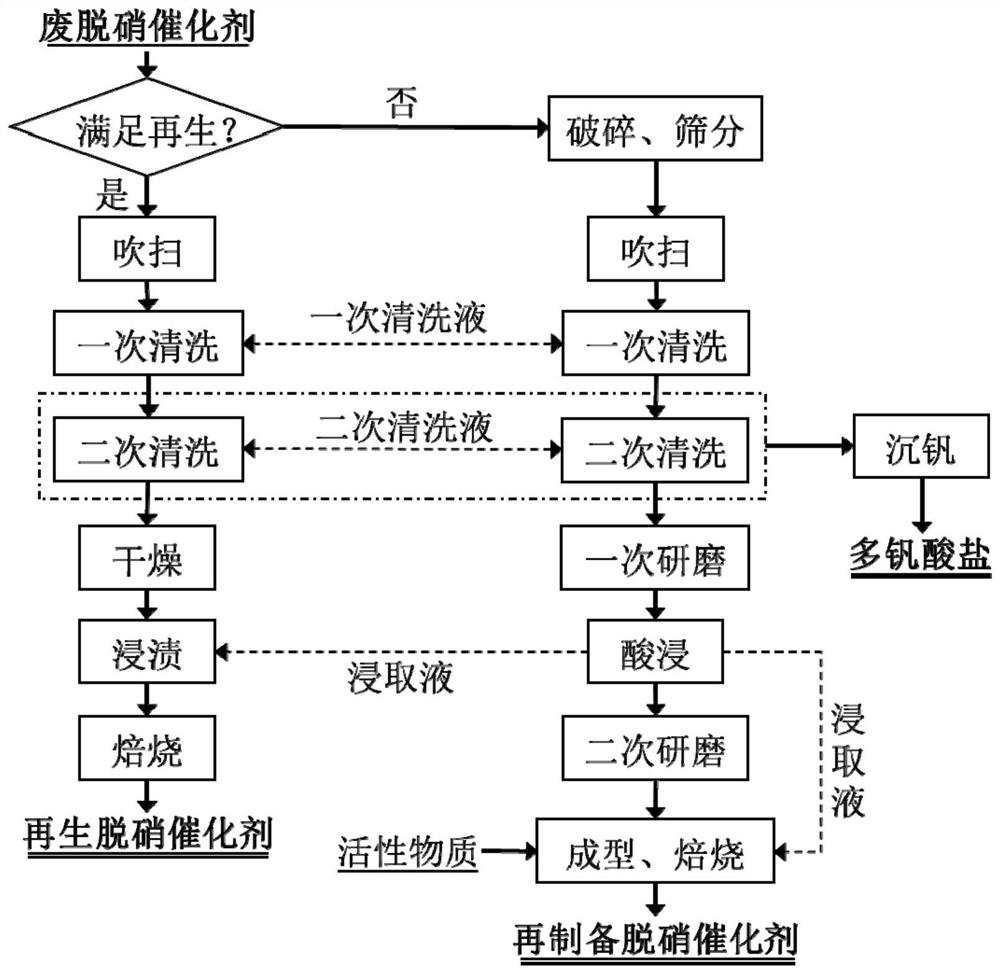

[0040] A method for green recycling of a honeycomb denitrification catalyst. Two process routes of regeneration and re-preparation arranged side by side are arranged, and a regeneration process or a re-preparation process is selected according to the performance of the waste honeycomb denitrification catalyst to implement green recycling; the regeneration process and The basis for the selection of the re-preparation process is: the axial and radial compressive strengths of the waste honeycomb denitration catalyst are ≥1.0 and ≥0.2MPa respectively, and the specific surface area is ≥40.0m 2 / g, the regeneration process route is selected; otherwise, the re-production process route is selected.

[0041] The regeneration process is as follows:

[0042] (1) Purge: Use air to purge the surface and channels of the spent catalyst, and the air pressure is 0.3 MPa; further use sound waves to detect the situation of purge dead ends and blocked holes, and when the blocked holes are found, ...

Embodiment example 2

[0064] A method for green recycling of a honeycomb denitrification catalyst. Two process routes of regeneration and re-preparation arranged side by side are arranged, and a regeneration process or a re-preparation process is selected according to the performance of the waste honeycomb denitrification catalyst to implement green recycling; the regeneration process and The basis for the selection of the re-preparation process is: the axial and radial compressive strengths of the waste honeycomb denitration catalyst are ≥1.0 and ≥0.2MPa respectively, and the specific surface area is ≥40.0m 2 / g, the regeneration process route is selected; otherwise, the re-production process route is selected.

[0065] The regeneration process is as follows:

[0066] (1) Purge: use air to purge the surface and channels of the spent catalyst, and the air pressure is 0.4MPa; further use sound waves to detect the situation of purge dead ends and blocked holes, and when the blocked holes are found, u...

Embodiment example 3

[0088] A method for green recycling of a honeycomb denitrification catalyst. Two process routes of regeneration and re-preparation arranged side by side are arranged, and a regeneration process or a re-preparation process is selected according to the performance of the waste honeycomb denitrification catalyst to implement green recycling; the regeneration process and The basis for the selection of the re-preparation process is: the axial and radial compressive strengths of the waste honeycomb denitration catalyst are ≥1.0 and ≥0.2MPa respectively, and the specific surface area is ≥40.0m 2 / g, the regeneration process route is selected; otherwise, the re-production process route is selected.

[0089] The regeneration process is as follows:

[0090](1) Purge: use air to purge the surface and channels of the spent catalyst, and the air pressure is 0.5 MPa; further use sound waves to detect the situation of purge dead ends and blocked holes, and when the blocked holes are found, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com