A novel fuel cell membrane electrode and its preparation method

A fuel cell membrane and electrode technology, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., to achieve the effects of convenient quality monitoring, increased current density, and easy replication to production or laboratory environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The first slurry (Formula-1 slurry) is a platinum-containing catalyst slurry:

[0061] (1) 15.3g 50wt% Umicore platinum-carbon catalyst (Vulcan XC carbon black);

[0062] (2) 21.2g D2020 Nafion solution;

[0063] (3) 31.8g deionized water

[0064] (4) 39.0g isopropyl alcohol

[0065] (5) 0.5g glycerin

[0066] (6) 0.05g water-soluble white dye, model BP-8095.

[0067] The second slurry (Formula-2 slurry) is a non-platinum catalyst slurry:

[0068] (1) 15.3g carbon black, model: Vulcan XC;

[0069] (2) 21.2g Nafion solution, model D2020;

[0070] (3) 31.8g deionized water

[0071] (4) 39.0g isopropyl alcohol

[0072] (5) 0.5g glycerin

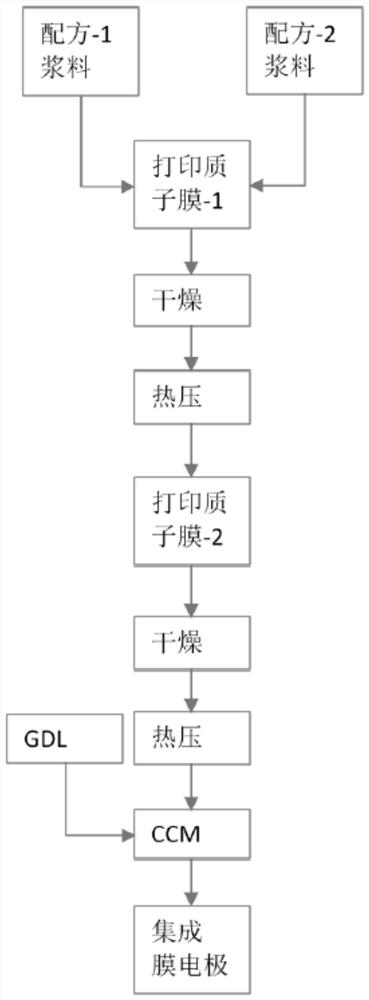

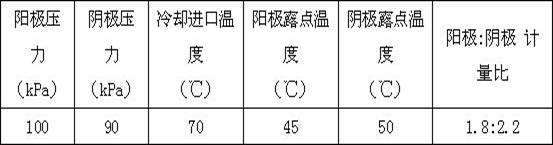

[0073] The first membrane electrode preparation process proposed by the present invention is as follows:

[0074](1) Slowly inject the above two slurries into the two ink cartridges of the inkjet printer with a syringe;

[0075] (2) Import the 2-D diagram of the plate design including the spine and the flow channel into the com...

Embodiment 2

[0081] The first slurry (Formula-1 slurry) is a platinum-containing catalyst slurry:

[0082] (1) 15.3g platinum carbon catalyst;

[0083] (2) 21.2g D2020 Nafion solution;

[0084] (3) 31.8g deionized water

[0085] (4) 39.0g isopropyl alcohol

[0086] (5) 0.5g glycerin

[0087] (6) 0.05g BP-8095 water-soluble white dye

[0088] The platinum-carbon catalyst includes platinum and carbon black, and the mass content of the platinum is 50%. The platinum is branded Umicore and the carbon black is Vulcan XC.

[0089] The second slurry (Formula-2 slurry) is a non-platinum catalyst slurry:

[0090] (1) 15.3g Vulcan XC carbon black;

[0091] (2) 21.2g D2020 Nafion solution;

[0092] (3) 31.8g deionized water

[0093] (4) 39.0g isopropyl alcohol

[0094] (5) 0.5g glycerin

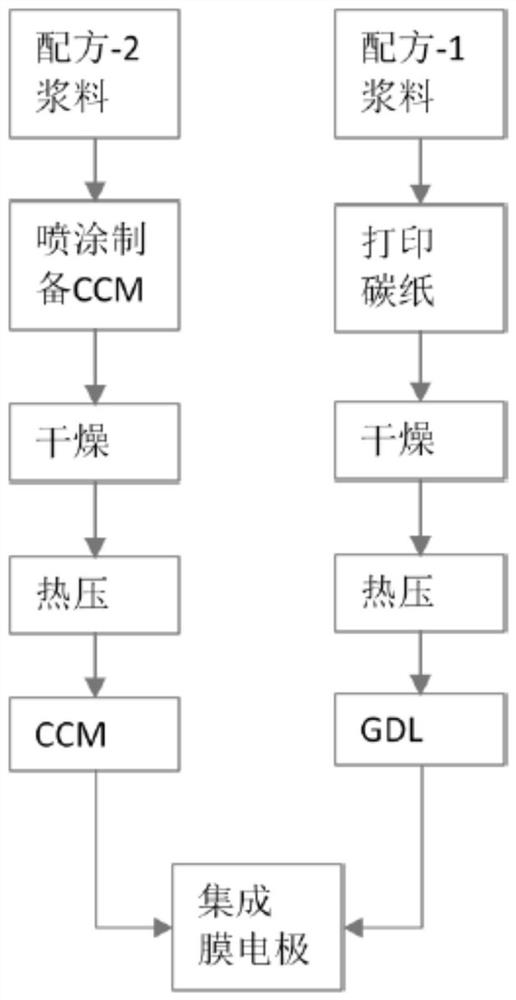

[0095] (1) The formula-2 slurry is uniformly applied to the cathode and anode sides of the proton exchange membrane by spraying, coating or printing, and then dried and hot-pressed to form CCM.

[0096] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com