Manufacturing method of miniature thermoelectric device

A technology for thermoelectric devices and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc. Problems such as inaccurate arrangement of thermoelectric particles can achieve the effect of improving performance consistency, ensuring contact accuracy, and reducing process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for designing a swing mold tool for the manufacture of micro-thermoelectric devices, comprising the following steps:

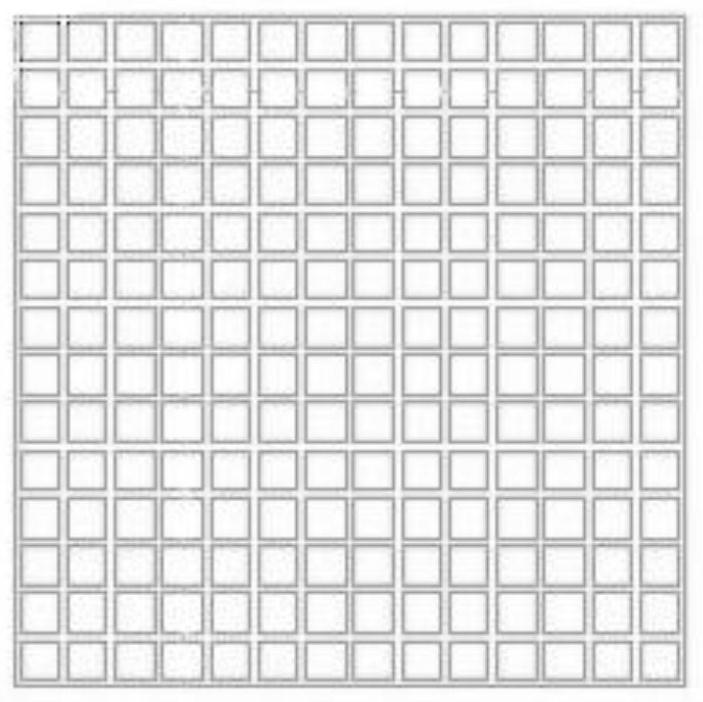

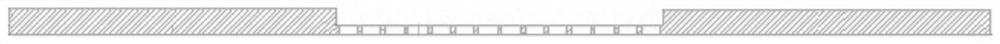

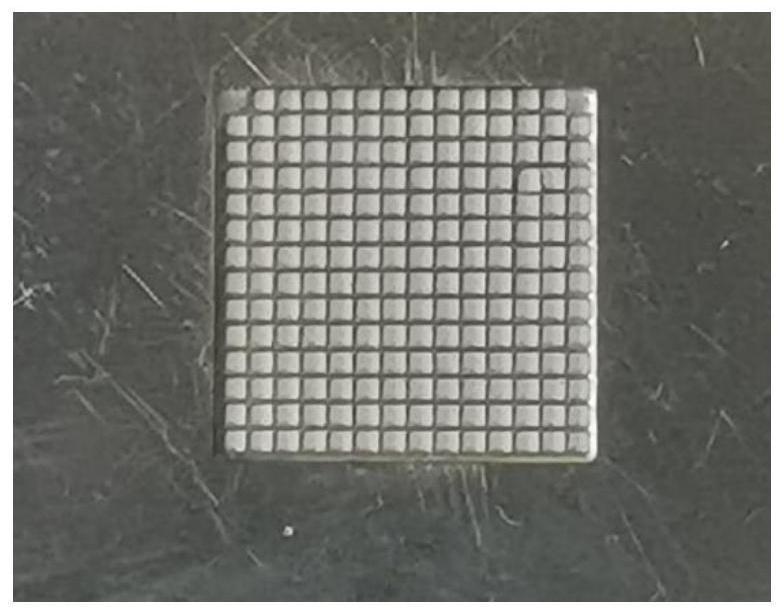

[0033] 1) The size of the miniature thermoelectric device to be manufactured in this embodiment is 8×8mm 2 , a total of 97 pairs of micro-thermoelectric particles; design steel mold drawings according to the requirements of the electrode substrate of micro-thermoelectric devices, such as figure 1 and figure 2 shown;

[0034] 2) Utilize the continuous laser to process the steel mold according to the drawings described in step 1); the steel mold includes a limiting plate and an outer frame located around the limiting plate, and the top surface of the limiting plate and the inner side of the outer frame form a concave The groove is used to accommodate the electrode substrate, and a plurality of square through holes are opened on the limiting plate to limit the position of the thermoelectric particles; the size of the groove matches the size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com