A Rigid True Triaxial Specimen Elastic Box Fixture and Rock Sample Displacement Monitoring Method

A true triaxial and elastic technology, applied in the field of rigid true triaxial specimen elastic box fixture and rock sample displacement monitoring, can solve the problems of cumbersome operation process, unable to meet six-sided rigid loading, unable to realize rock burst test research, etc. Achieve the effect of reducing operation steps, ensuring accuracy and saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

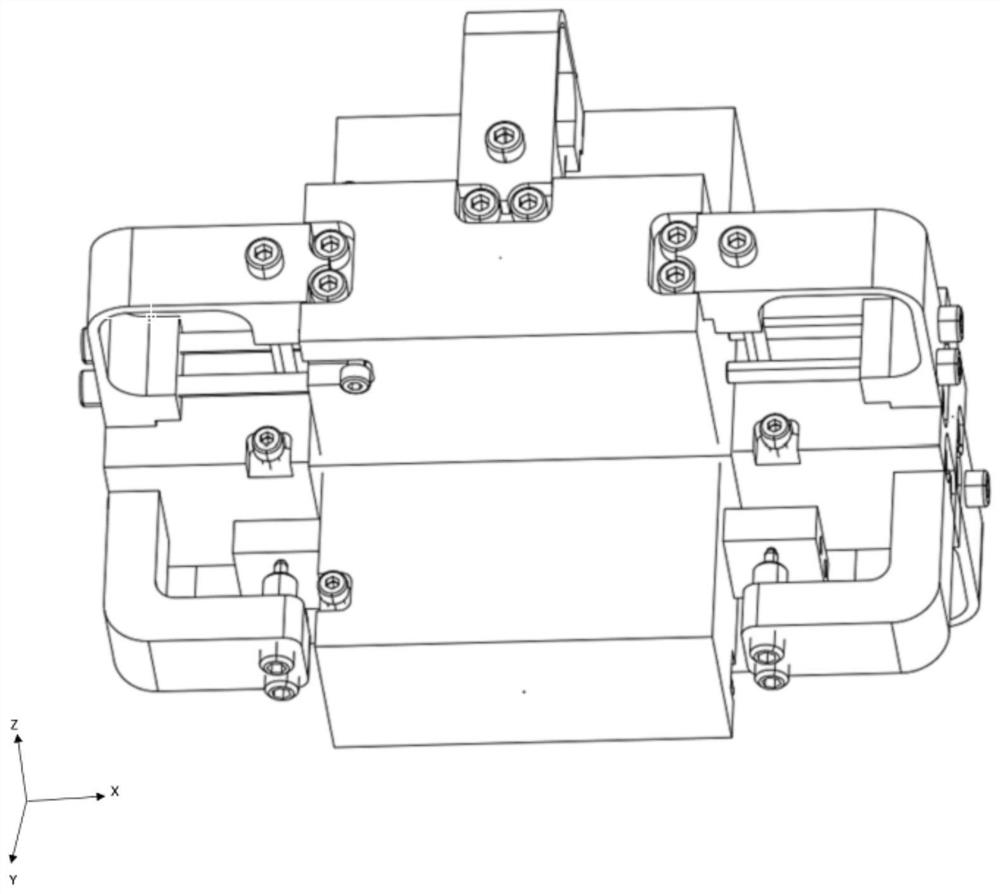

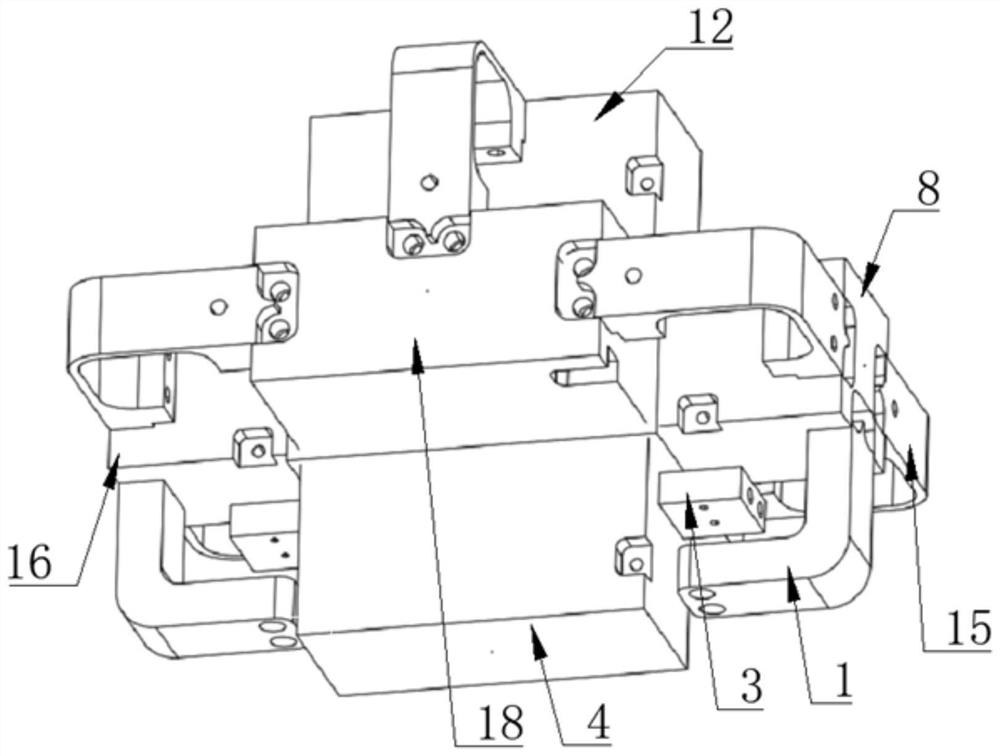

[0040] The overall structure of the rigid true triaxial specimen elastic box fixture of this embodiment is as follows figure 1 shown, including:

[0041] 6 pressing plates and 8 leaf springs, the positional relationship between the pressing plates and the springs is as follows figure 2 Shown:

[0042] The 6 pressing plates form a 6-hedron hollow box-like structure, each face of the 6-hedron hollow-box-like structure is provided by a pressing plate respectively, with the center of the 6-hedron hollow-box-like structure as the coordinate origin, and the direction perpendicular to the 6 faces Establish a space Cartesian coordinate system, the pressing plates on the two fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com