A method for measuring solvent volume by optical fiber

A solvent volume and solvent technology, which is applied in the field of measuring solvent volume by optical fiber, can solve the problems of deviation of data results, immaturity of rapid volatilization of solvent volume, and dependence on complex measuring devices, etc. The effect of manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

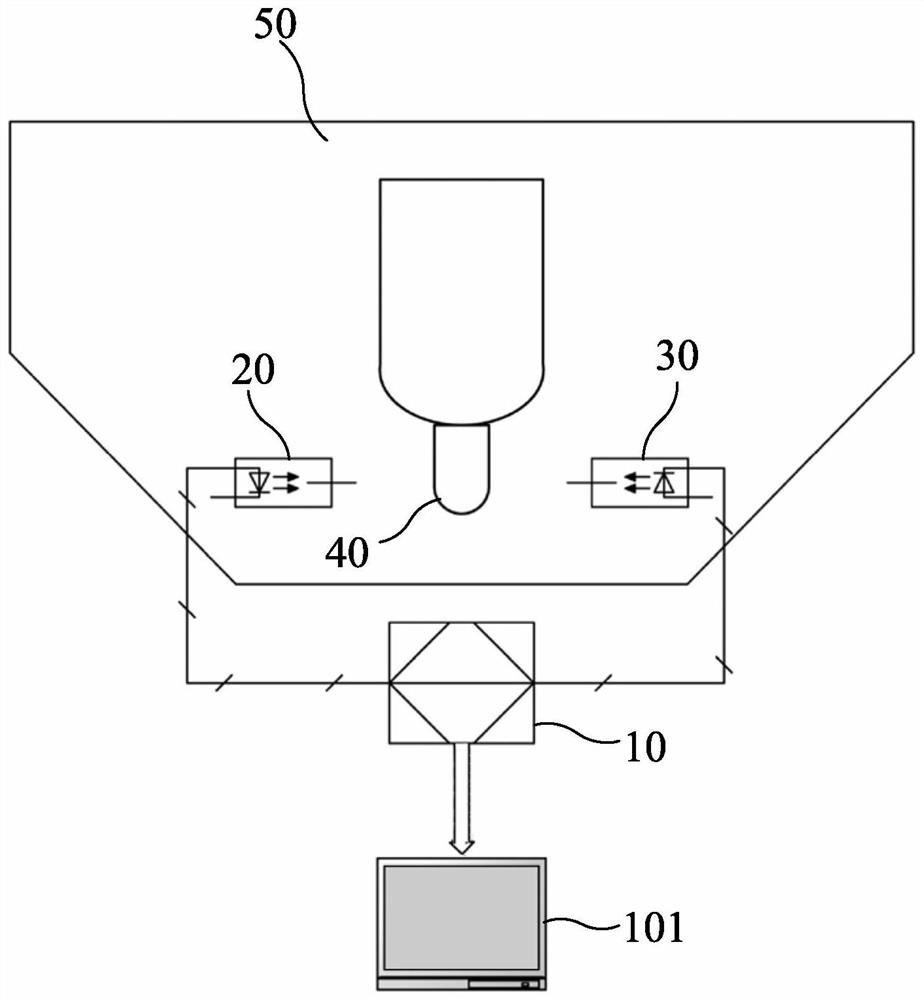

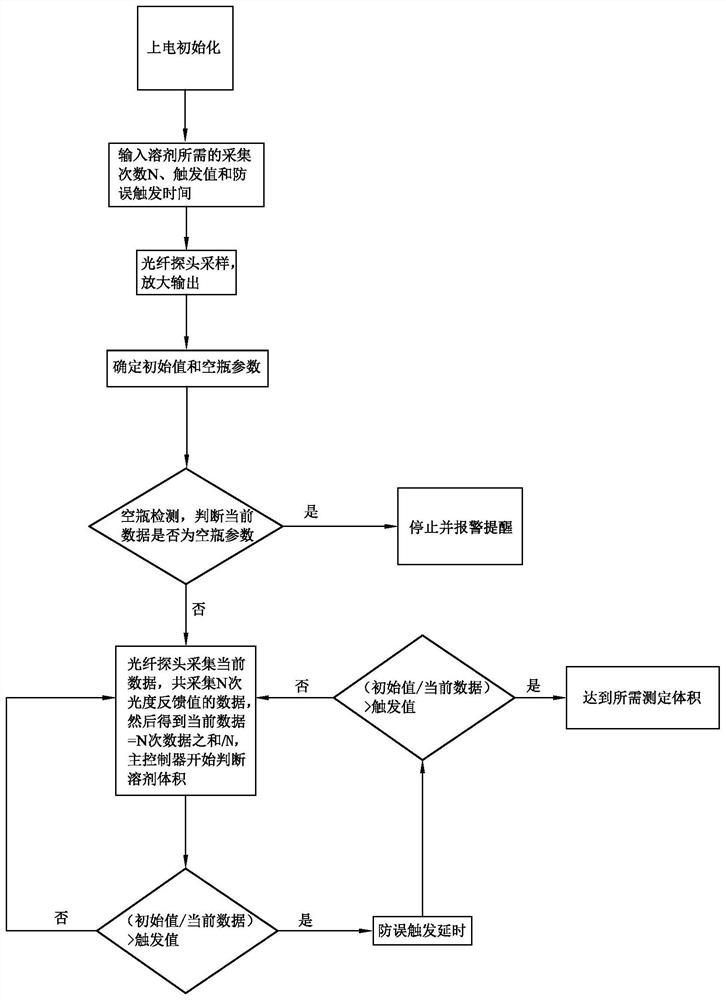

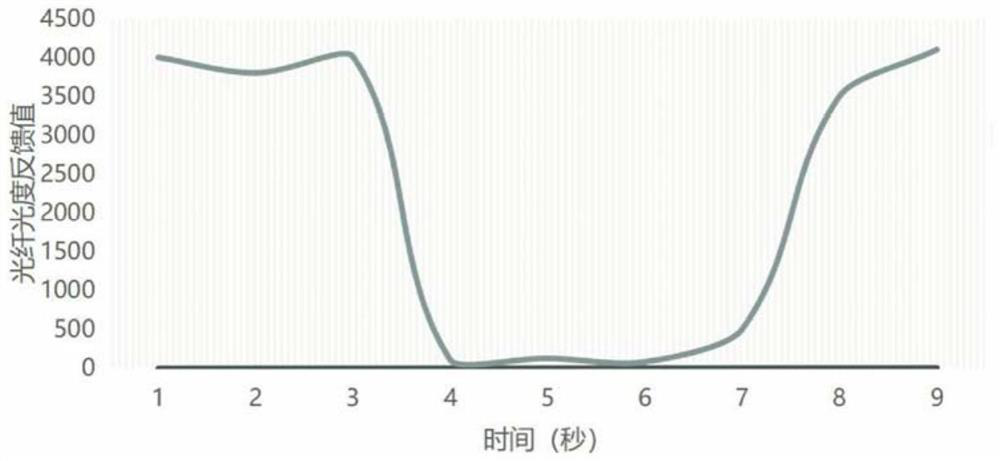

[0020] The invention provides a method for measuring solvent volume by optical fiber, such as figure 1 As shown, the method involves components including the main controller 10, the panel 101, the fiber optic probes 20, 30, the reagent bottle 40 and the water tank 50, combined with figure 2 , the method includes the following steps:

[0021] S1 Preparation before work: the main controller 10 is connected to the optical fiber probes 20, 30, the reagent bottle 40 is placed in the water tank 50, the optical fiber probes 20, 30 are stretched into the water tank 50, and placed symmetrically on both sides of the reagent bottle 40;

[0022] S2 power-on initialization: the main controller is powered on, and the number of acquisitions N, trigger value and anti-false trigger time required for the solvent are input on the panel 101 of the main controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com