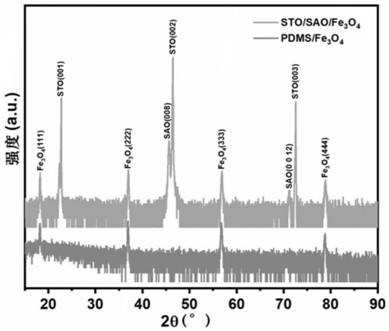

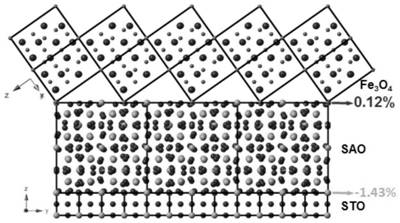

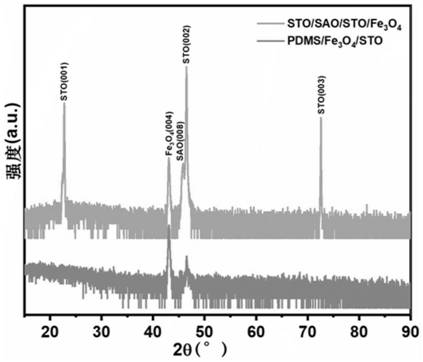

Preparation of flexible self-supporting single crystal Fe3O4 thin film material capable of self-regulating growth orientation, thin film material, and single crystal structure

A technology of growth orientation and thin film materials, which is applied in the field of growth orientation of flexible self-supporting crystal structures, can solve the problems of narrow application range of thin films, and achieve the effects of promoting production, expanding applications, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A flexible self-supporting single crystal Fe with self-regulated growth orientation 3 o 4 The preparation method of film material, comprises the following steps:

[0071] (1) Select the STO (001) substrate and preprocess it, including the following steps:

[0072] a. Immerse the STO (001) substrate in acetone, and ultrasonically clean it at 60°C for 10 minutes;

[0073] b. Then immerse the STO (001) substrate in absolute ethanol, and ultrasonically clean it for 5 minutes;

[0074] c. Then immerse the STO (001) substrate in deionized water and ultrasonically clean it for 5 minutes;

[0075] d. Finally, dry the STO (001) substrate with nitrogen.

[0076] (2) The single crystal SAO layer, STO layer and Fe 3 o 4 Thin film material specifically comprises the following steps:

[0077] (a) Paste the STO (001) substrate pretreated in step (1) on the SiC heat conduction sheet with silver paste, and then heat and dry;

[0078] (b) Place the SiC heat conduction sheet paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell parameters | aaaaa | aaaaa |

| Cell parameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com