High-temperature-resistant and high-humidity-resistant water-based box pasting adhesive and preparation method thereof

A box glue, high temperature resistant technology, applied in the direction of adhesives, carboxyl rubber adhesives, polymer adhesive additives, etc., can solve the problems of not being able to adapt to high humidity, high temperature and high humidity performance improvement, etc., to prevent the problem of glue opening , Satisfying the effect of high and low temperature resistance and high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides the preparation method of above-mentioned water-based box glue, and this preparation method comprises the following steps:

[0031] Step 1, adding the weighed polyacrylate emulsion into the container;

[0032] Step 2. Add the weighed carboxylated styrene-butadiene latex, vinyl acetate-ethylene copolymer emulsion, water-based tackifying resin, water-based one-component crosslinking agent, wetting agent, and defoaming agent to the container in sequence under the stirring action of the disperser. agent and preservative, stirring for 20min under the condition of 300~500r / min;

[0033] Step 3. Continue to add thickener to the container until the viscosity of the system reaches 8000-13000mPa·s;

[0034] Step 4, using a filter screen to filter to obtain water-based box glue.

[0035] Wherein, in step 1, the container is a beaker, and the weighing tool is an electronic balance; in step 2, the disperser is a stirring sand mill disperser; in ...

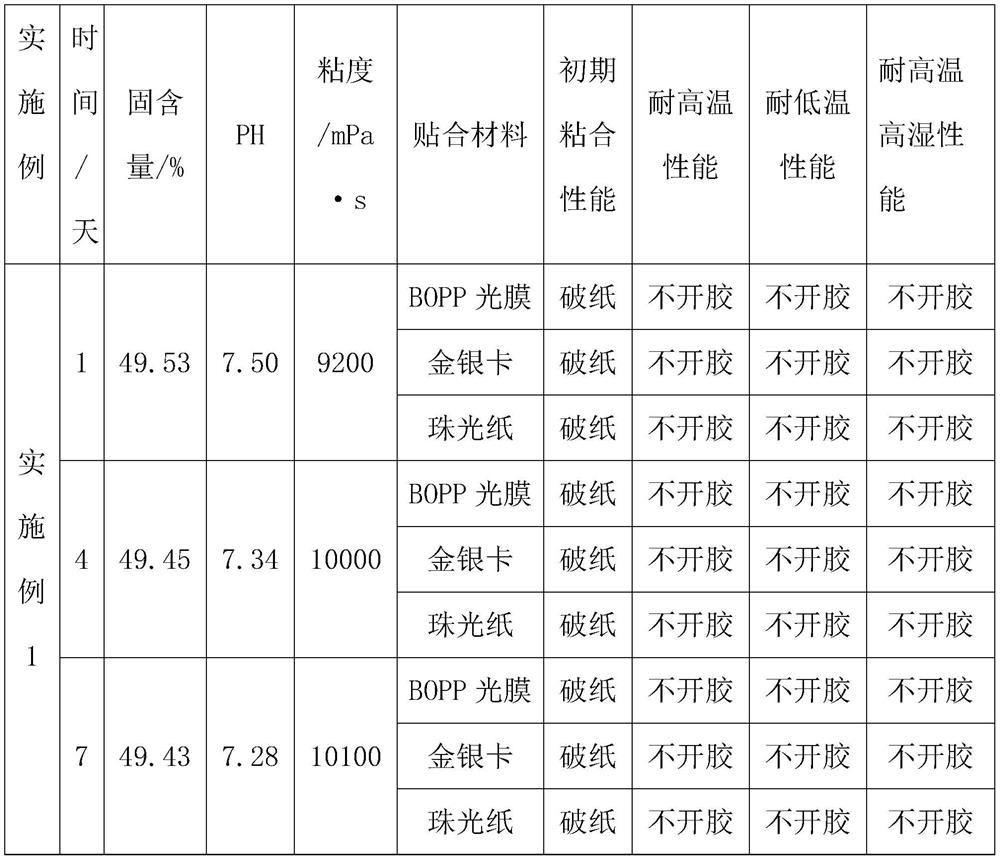

Embodiment 1

[0048] In this embodiment, the water-based box glue includes the following components: 80 parts of water-based polymer, 20 parts of water-based tackifying resin, 2.5 parts of water-based one-component crosslinking agent, 0.3 parts of defoaming agent, 0.2 parts of wetting agent, 0.1 part of preservative, 0.8 part of thickener. Among them, the water-based polymer is a mixture of polyacrylate emulsion, carboxylated styrene-butadiene latex and vinyl acetate-ethylene copolymer emulsion, and the ratio of polyacrylate emulsion, carboxylated styrene-butadiene latex and vinyl acetate-ethylene copolymer emulsion is 40:20 : 20; the water-based tackifying resin is rosin polyol resin; the water-based one-component crosslinking agent is a mixture of ionic crosslinking agent and multifunctional adhesion promoter, and the ratio of ionic crosslinking agent and multifunctional adhesion promoter For: 1.0:1.5; defoamer is mineral oil defoamer; wetting agent is sodium sulfosuccinic acid diester; p...

Embodiment 2

[0050] In this example, the composition of the water-based box glue is similar to that of Example 1, except that it is different from Example 1: 80 parts of water-based polymer, polyacrylate emulsion, carboxylated styrene-butadiene latex and vinyl acetate-ethylene copolymer The ratio of the emulsion is: 30:30:20; the ratio of the water-based one-component cross-linking agent is 2.5 parts, and the ratio of the ionic cross-linking agent and the multifunctional adhesion promoter is: 1.5:1.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com