Valganciclovir hydrochloride preparation method

A technology of valganciclovir hydrochloride and hydrochloric acid, applied in the field of valganciclovir hydrochloride preparation, can solve the problems of inability to meet industrial production requirements, inability to continuous production, long reaction time, etc., and achieves a high degree of automation, material in and out Convenience and controllable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

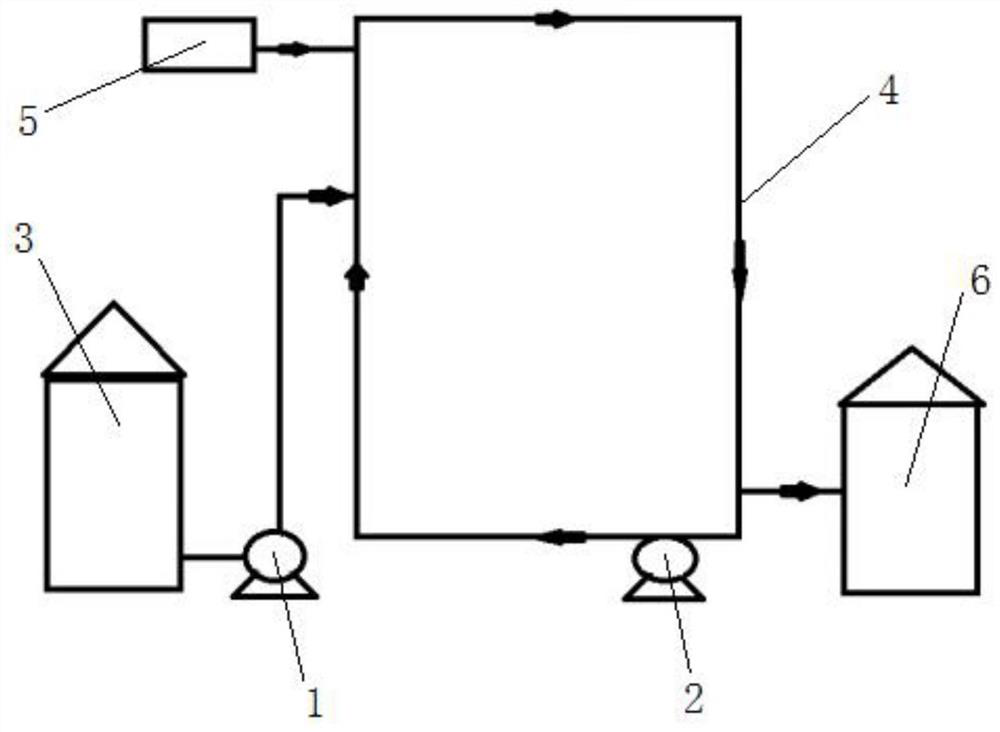

[0032] like figure 1 The shown equipment for preparing valganciclovir hydrochloride includes material tank 3, tubular reactor 4, hydrogen tank 5, receiving tank 6 and reactor (not shown in the figure), and material tank 3 and tube The first pump body 1 is arranged between the reactors 4, and the second pump body 2 is arranged on the tubular reactor 4. The inlet and outlet of the tubular reactor 4 adopt 316 steel high-quality check valves, which are stable and safe.

[0033] use as figure 1 Shown equipment prepares a kind of valganciclovir hydrochloride, comprises the steps:

[0034] S1, loading catalyst: before loading the catalyst, the tubular reactor 4 is checked, and the reactor is required to be unimpeded, clean, free of debris, and replaced with nitrogen gas (purging and drying with nitrogen gas), and then 15kg 5% Pd / C is filled in tubular reactor 4 (tubular reactor 4 adopts conventional horizontal tubular reactor, model JHF-1, Nantong Walchi Petrochemical Engineering ...

Embodiment 2

[0045] use as figure 1 Shown equipment prepares a kind of valganciclovir hydrochloride, comprises the steps:

[0046] S1, loading catalyst: before loading the catalyst, the tubular reactor 4 is checked, and the reactor is required to be unimpeded, clean, free of debris, and replaced with nitrogen gas (purging and drying with nitrogen gas), and then 205kg 5% Pd / C is filled in tubular reactor 4 (tubular reactor 4 adopts conventional horizontal tubular reactor, model JHF-1, Nantong Walchi Petrochemical Engineering Co., Ltd.);

[0047] S2, reactant dissolving: put 120kg monoester and 120kg methanol, 20kg concentrated hydrochloric acid into the 500L reactor and stir to dissolve, and put the dissolved material into the material tank 3;

[0048] S3, open the first pump body 1 to pass the material in the material tank 3 into the tubular reactor 4, and then open the second pump body 2, so that the material circulates in the tubular reactor 4;

[0049] S4. Detect the content of oxyge...

Embodiment 3

[0056] based on figure 1 As shown in the equipment for preparing valganciclovir hydrochloride, the receiving tank 6 is communicated with the material tank 3 through a pipeline, and the pipeline is provided with a valve (this pipeline and valve are not shown in the figure).

[0057] Utilize above-mentioned equipment to prepare a kind of valganciclovir hydrochloride, comprise the steps:

[0058] S1, loading catalyst: before loading the catalyst, the tubular reactor 4 is checked, and the inside of the reactor is required to be unimpeded, clean, free of debris, and qualified for replacement with nitrogen (purging and drying with nitrogen), and then 210kg 5% Pd / C is filled in tubular reactor 4 (tubular reactor 4 adopts conventional horizontal tubular reactor, model JHF-1, Nantong Walchi Petrochemical Engineering Co., Ltd.);

[0059] S2, reactant dissolution: put 120kg monoester and 120kg methanol, 24kg concentrated hydrochloric acid into 500L reactor and stir to dissolve;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com