Silica-based cement-based porous material and preparation method thereof

A technology of silica and porous materials, which is applied in the field of building materials, can solve the problems of weakening of the mechanical properties of cement-based porous materials and the reduction of mechanical properties of porous materials, and achieve the benefits of material strength, increasing the proportion of nanopores, and strengthening the microstructure. Effect

Active Publication Date: 2022-05-31

SOUTHWEAT UNIV OF SCI & TECH

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

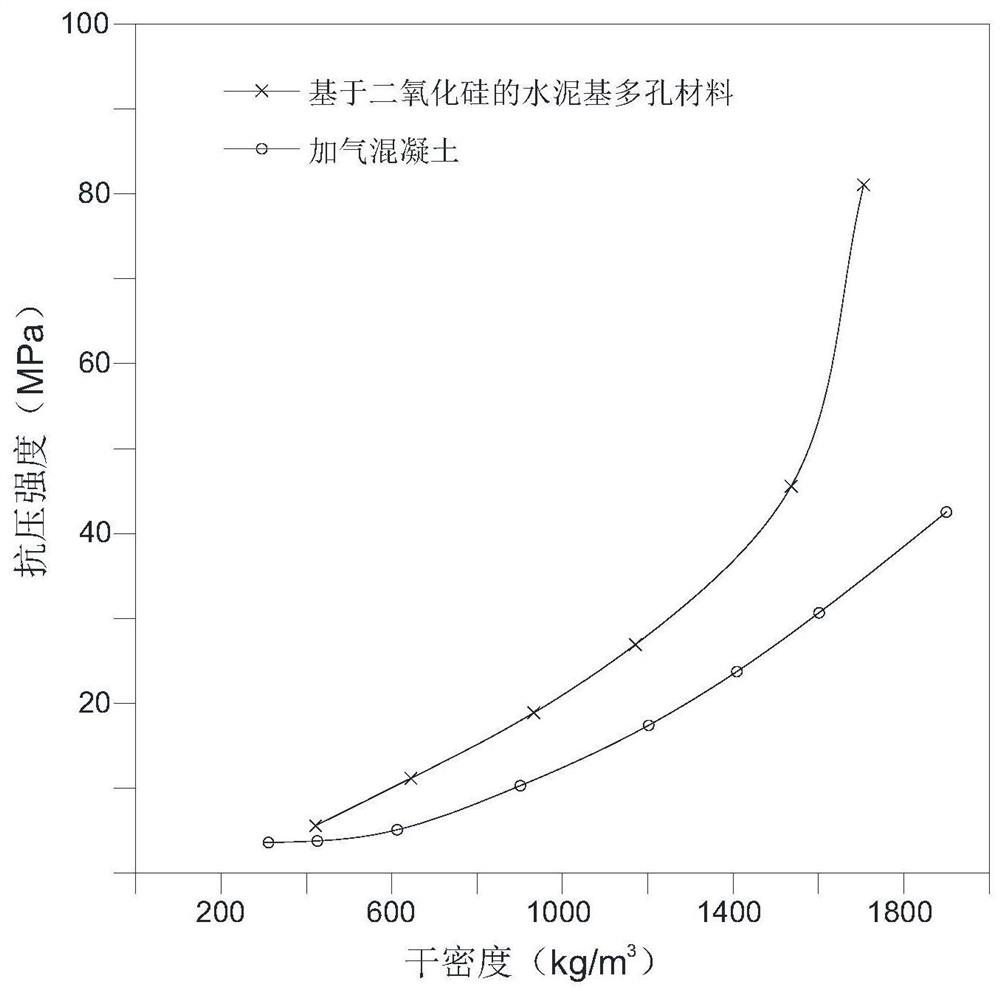

[0003] Introducing more pore structures into cement-based materials can achieve ultra-lightweight materials and further improve their thermal insulation performance, but at the same time, the introduction of pores will also lead to a significant weakening of the mechanical properties of cement-based porous materials, especially when the pore size is 0.1 μm The higher the pore content above, the mechanical properties of the porous material will decrease significantly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] S4, the intermediate slurry is molded and maintained, and then dried to obtain a cement-based porous material.

Embodiment 2

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of building materials, and discloses a silica-based cement-based porous material and a preparation method thereof. The cement-based porous material is mainly composed of cement, admixtures, water, admixtures, and a silica dispersion, and then hardened by coagulation Obtain; wherein the silica dispersion is a dispersion system formed by dispersing silica particles in water. In the present invention, because the cement hydration reaction fails to completely consume the introduced water, a large amount of capillary space is formed, and the cement hydration product reacts with spherical silica on the surface of the silica, and the cement hydration product grows on the silica, The overlapping of each other can refine and divide the capillary space, and build a large number of nanopore spaces in the capillary space, increasing the proportion of nanopores in the cement composite porous material; at the same time, through the construction of the capillary space by the nanopore structure, the strength of the material is strengthened. The microstructure is conducive to the development of material strength and improves the mechanical properties of cement-based porous materials.

Description

Silica-based cement-based porous material and preparation method thereof technical field The present invention relates to the technical field of building materials, be specifically related to the cement-based porous material based on silica and its preparation. preparation method. Background technique Cement-based porous materials are used as building thermal insulation materials due to the advantages of simple process, low cost, safety and fire prevention. There is a huge potential in the field of cement-based porous materials. It is prepared by entraining air inside the material to form pores or carrying the cellular structure into the cement-based material through prefabricated foam, lightweight aggregate, etc. Cement-based materials with rich pore structure. Introducing more pore structures into cement-based materials can achieve ultra-lightweight materials and further improve its retention. Thermal insulation performance, but at the same time the introductio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/00C04B28/04C04B38/00C04B14/06

CPCC04B28/00C04B28/04C04B38/00C04B2201/20C04B2201/50C04B2201/52C04B18/141C04B18/08C04B18/146C04B2103/0068C04B20/0048C04B14/06C04B2103/302C04B2103/22C04B2103/12C04B38/0054C04B38/0067C04B38/0074Y02W30/91

Inventor 蒋俊李军卢忠远

Owner SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com